What is Advanced Manufacturing and Why It Matters

What is advanced manufacturing is a critical question for modern businesses. In short, it is the use of innovative technologies to improve products and processes. It integrates cutting-edge tools like robotics, AI, and data analytics to create more efficient, precise, and customizable production systems.

Key characteristics of advanced manufacturing include:

- Technology Integration: Uses AI, robotics, IoT sensors, and automation

- Data-Driven Operations: Leverages real-time analytics and digital twins

- Customization Focus: Enables mass customization vs. mass production

- Sustainability: Reduces waste through precision and circular manufacturing

- Workforce Evolution: Requires skilled technicians vs. traditional manual labor

This represents a fundamental change from traditional, manual-heavy manufacturing. The economic impact is staggering: American manufacturers contribute over $2.35 trillion to the U.S. economy, and every dollar spent in manufacturing adds $2.79 to the economy—the highest multiplier of any sector.

Modern manufacturers are shifting from isolated processes to interconnected, real-time systems. This enables faster market response, lower costs, and innovative product creation.

I’m Louis Balla, CRO and partner at Nuage. With over 15 years in digital change and supply chain optimization, I’ve seen how understanding advanced manufacturing transforms businesses, especially when maximizing their NetSuite implementations.

What is Advanced Manufacturing and How Does It Differ from Traditional Methods?

When we ask what is advanced manufacturing, we’re talking about a reimagining of how things get made. It uses innovative technology to boost competitiveness by optimizing the entire value chain, from product conception to end-of-life. This is achieved by integrating information and communication technology (ICT) into all manufacturing and business operations.

This philosophy combines information, automation, computation, software, sensing, and networking to create highly efficient and responsive operations, making it a necessity for staying competitive in today’s global market.

The Purpose of Advanced Manufacturing

The core goal of advanced manufacturing is to make better products, faster, and at a lower cost than competitors, without sacrificing quality.

- Better quality is achieved through precision manufacturing, real-time monitoring, and advanced materials.

- Faster production results from automation, data-driven insights, and streamlined processes that cut lead times.

- Lower costs are realized through reduced waste, smart resource allocation, and predictive maintenance.

The key is market responsiveness. Flexible systems allow for quick pivots and customization without high costs. Sustainability is another benefit, as optimized energy use and minimal waste improve both environmental impact and the bottom line. This all adds up to improved competitiveness and long-term growth.

Traditional Manufacturing in Contrast

Contrasting advanced manufacturing with traditional methods highlights its significance. While traditional manufacturing built modern industry, it operates on different principles, relying on mass production, standardization, and sequential assembly lines. Its workforce is often trained on the job, and investment focuses on physical assets like machinery.

Advanced manufacturing prioritizes customization and flexibility through integrated, data-driven systems. It requires a highly skilled, tech-proficient workforce in “new collar” jobs, capable of critical thinking and continuous learning.

| Feature | Traditional Manufacturing | Advanced Manufacturing |

|---|---|---|

| Production Strategy | Mass production, standardization | Customization, flexibility, rapid prototyping, agile production |

| Labor & Skills | Manual labor, specialized but often semi-skilled, on-the-job training | Highly skilled, tech-proficient, critical thinking, continuous learning, “new collar” jobs |

| Investment Focus | Physical infrastructure (factories, machinery) | Digital infrastructure (IT, software, data systems), R&D, workforce training |

| Logistics | Traditional channels (trucks, rail), local supply chains | Global supply chain management, real-time tracking, optimized routes |

This shift demands sophisticated business systems to manage complexity, connect data, and provide the real-time visibility needed for success.

The Core Technologies Driving the Revolution

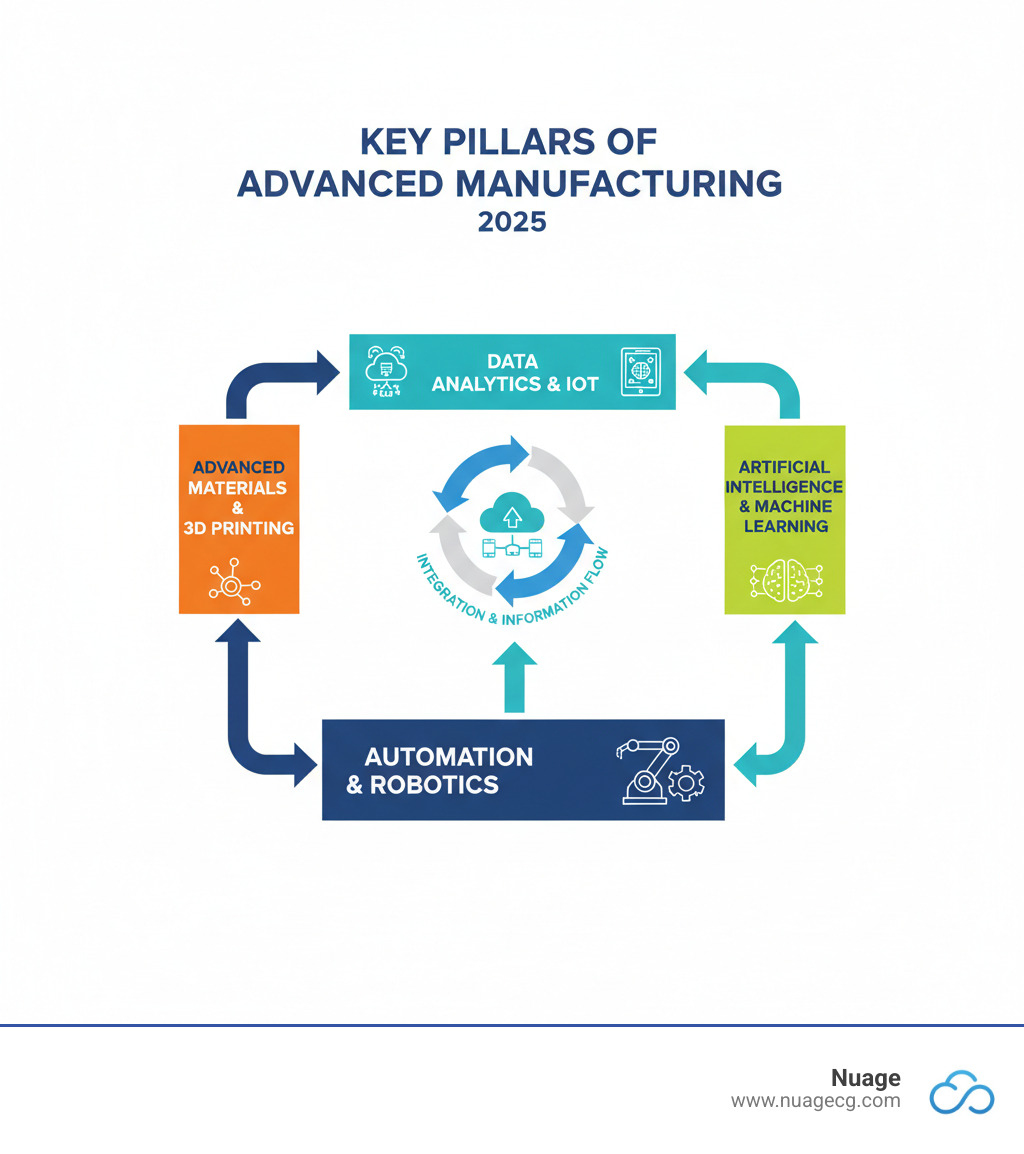

The answer to what is advanced manufacturing lies in how its core technologies work together. It’s the integration of digital and physical systems, often called Industry 4.0 or the “smart factory,” creating intelligent, interconnected ecosystems where machines, systems, and people collaborate.

This complexity requires robust business systems. Many companies struggle when back-office systems can’t handle the data and integration demands. At Nuage, we help clients leverage platforms like NetSuite to connect every piece of their advanced manufacturing puzzle (see the official site at NetSuite.com). Explore our NetSuite services

Let’s explore the technologies making this revolution possible.

Additive Manufacturing (3D Printing)

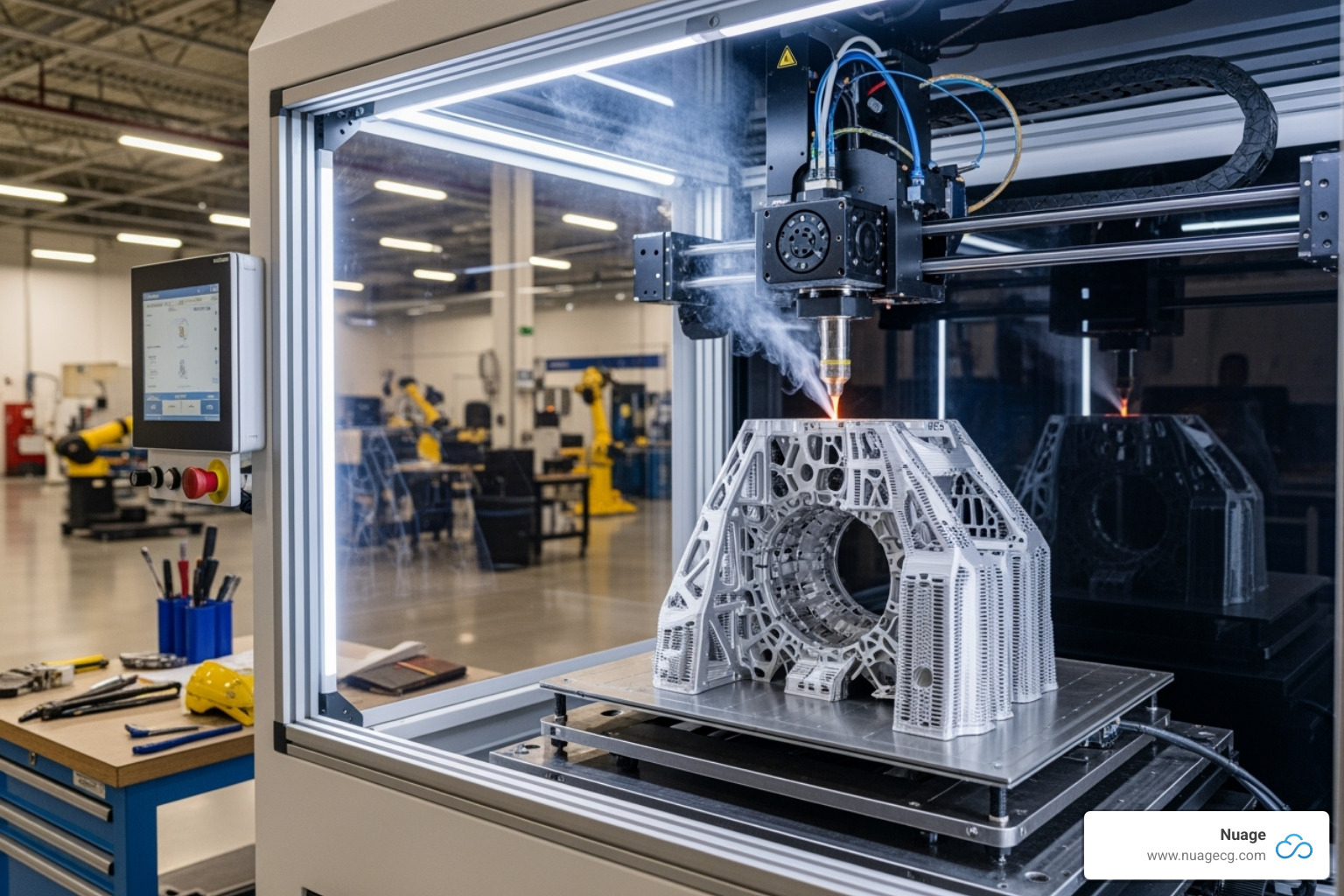

Additive Manufacturing (3D printing) reverses traditional subtractive methods. Instead of cutting material away, it builds objects layer by layer from a digital design. This enables rapid prototyping, the creation of complex geometries impossible with traditional machining, and strong, lightweight parts that use significantly less material.

The process drastically reduces waste and allows for cost-effective customized products without retooling, opening up new niche markets. The U.S. government supports this technology through initiatives like America Makes, the National Additive Manufacturing Innovation Institute. Visit the America Makes website

Artificial Intelligence (AI) & Machine Learning (ML)

AI and Machine Learning (ML) give manufacturing systems the ability to learn and make autonomous decisions.

- Predictive maintenance is a key application. AI analyzes sensor data to predict equipment failure, reducing costly unplanned downtime.

- Quality control automation uses AI vision systems to spot defects with superhuman speed and accuracy.

- Process optimization uses ML to continuously fine-tune production for maximum efficiency.

- Demand forecasting analyzes vast datasets to create production schedules that align with real market demand.

Managing these data flows requires tools like Salesforce NetSuite Connectors to ensure insights reach decision-makers. For CRM and sales automation, many manufacturers rely on Salesforce as an authoritative platform.

Internet of Things (IoT) & Big Data

The Internet of Things (IoT) is the nervous system of advanced manufacturing, embedding smart sensors into equipment to collect and share data. Big Data is the brain that processes this information. With 74% of manufacturers adopting Industrial IoT, this technology is now fundamental.

This real-time data collection provides unprecedented operational visibility for proactive problem-solving. Digital twin technology improves this by creating virtual replicas of physical assets for simulation and optimization, enabling massive performance gains.

Supply chain visibility is also improved by tracking materials in real-time, leading to significant savings. Making sense of this data is a challenge, which is why integrated ERP systems are crucial for turning raw data into actionable insights, as explained in our NetSuite 101 guide.

Robotics and Automation

Robotics and automation are highly visible, yet often misunderstood. The goal is not to replace humans, but to create partnerships where technology handles repetitive tasks, freeing people for more complex work.

- Repetitive task automation is a primary use, as robots excel at physically demanding or monotonous jobs.

- Increased precision is essential for industries with tight tolerances, like electronics.

- Worker safety improves dramatically when robots handle hazardous tasks.

- Collaborative robots (cobots) are designed to work safely alongside people, acting as sophisticated tools that assist with tasks.

With over 4 million industrial robots in use worldwide, productivity gains are significant. The Advanced Robotics for Manufacturing (ARM) Institute is focused on advancing this technology and developing the workforce.

Key Benefits and Real-World Industry Applications

When discussing what is advanced manufacturing, executives are often amazed by the tangible benefits already being realized. The results extend far beyond the factory floor.

Companies see increased efficiency from streamlined, data-driven processes. Improved productivity gains can reach 30-50%, while significant cost reduction comes from less waste, optimized labor, and predictive maintenance. Advanced manufacturing also delivers improved product quality through precision and real-time monitoring, leading to faster time-to-market.

These benefits span multiple industries.

Aerospace and Defense

The aerospace industry uses advanced manufacturing to meet its extreme precision and performance requirements. Lightweight composite materials have revolutionized aircraft design, improving fuel efficiency. 3D printing enables complex geometries, allowing for single-piece, high-precision components that reduce assembly time and failure points. NASA is even developing in-space manufacturing capabilities, which could revolutionize long-duration space missions. NASA’s work in advanced manufacturing

Automotive

Advanced manufacturing is central to the automotive industry’s shift toward electric and autonomous vehicles. Electric vehicle (EV) production relies on advanced materials and processes for batteries, motors, and lightweight structures. Modern automated assembly lines use AI to adapt to different vehicle configurations, ensuring precision and quality. Rapid prototyping with 3D printing dramatically accelerates innovation, allowing engineers to test new components in days.

Pharmaceutical and Medical

In healthcare, advanced manufacturing enables personalized medicine and helps address drug shortages. 3D printing allows for patient-specific implants and surgical guides customized to an individual’s anatomy, improving outcomes. The FDA supports continuous manufacturing for drugs, a method that improves quality and reduces costs. Bioprinting, the 3D printing of biological materials, has the potential to create tissues and organs for research and transplantation. The pandemic also highlighted the agility of 3D printed medical devices in filling supply chain gaps. FDA’s perspective on advanced manufacturing

Electronics and Semiconductors

In the electronics industry, advanced manufacturing pushes the boundaries of “smaller, faster, cheaper.” Nanotechnology enables the manipulation of matter at the atomic level, creating materials with new properties for tiny, high-performance components. Laser machining offers the extreme precision required for delicate electronics. Advanced processes also enable the production of flexible electronics, such as bendable displays and wearable sensors. Recognizing the sector’s strategic importance, the U.S. government invests in its growth through agencies like NIST. NIST awards for semiconductor manufacturing

The Impact on the Workforce and National Initiatives

Advanced manufacturing is creating exciting workforce changes. Rather than replacing jobs, it’s creating new career paths that blend technical expertise with creative problem-solving. This shift lifts workers into partners with intelligent systems, moving them from repetitive tasks to roles requiring critical thinking and data analysis, which often come with better pay and job satisfaction.

How is what is advanced manufacturing changing the workforce?

The modern factory floor is transformed. Workers now program robots, analyze data, and troubleshoot automated systems. This has created “new collar” jobs that prioritize technical skills over traditional degrees, a shift acceptd through skills-based hiring.

The World Economic Forum highlights fast-growing emerging roles in manufacturing, including AI and machine learning specialists, data analysts, and digital change specialists. Essential skills include robotics programming, machine learning, AI applications, additive manufacturing, IoT, data management, and CAD/CAM proficiency. Soft skills like critical thinking, adaptability, and communication are equally vital.

Community colleges are crucial for meeting this demand, with programs offering accelerated training for well-paid roles like Maintenance, Process, and Engineering Technicians.

The Role of Government and Federal Initiatives

The U.S. government recognizes advanced manufacturing as essential for economic growth, national security, and supply chain resilience. A strong domestic manufacturing base reduces dependence on foreign suppliers for critical goods and improves military readiness.

Recent disruptions have shown the fragility of global supply chains. Advanced manufacturing offers solutions like localized production and flexible systems that can adapt quickly. The government fosters public-private partnerships like the Manufacturing USA network, whose institutes develop new technologies and train the workforce. Visit the Manufacturing USA network

Federal investment flows through agencies like the Economic Development Administration (workforce grants), the National Science Foundation (research), and the National Institute of Standards and Technology (support for small businesses). These efforts align with the National Strategy for Advanced Manufacturing, aiming to secure U.S. leadership in the sector.

Frequently Asked Questions about Advanced Manufacturing

Having worked with countless manufacturers, I’ve seen the same questions about what is advanced manufacturing come up time and again. Here are answers to the most common inquiries.

What is the difference between smart manufacturing and advanced manufacturing?

These terms are often used interchangeably, but they have a subtle distinction.

- Advanced manufacturing is the broad term for any innovative technology or process—like advanced materials, 3D printing, or robotics—that improves manufacturing. These elements don’t have to be fully interconnected.

- Smart manufacturing is a subset of advanced manufacturing. It specifically refers to systems that are highly interconnected, data-driven, and automated, using AI, IoT, and cloud computing to create self-optimizing environments.

In short, all smart manufacturing is advanced, but not all advanced manufacturing is smart. For example, a factory where machines communicate and self-adjust is ‘smart.’ A factory using standalone 3D printers is ‘advanced’ but not necessarily ‘smart.’

What are the biggest challenges to adopting advanced manufacturing?

Understanding these obstacles can help you plan more effectively.

- High initial investment: Implementing new technologies requires significant upfront capital, which can be a barrier for small and medium-sized manufacturers.

- Workforce skills gap: There is a shortage of workers with the necessary skills in robotics, data analytics, and AI. Finding and retaining talent is a major challenge.

- Data security: Increased connectivity creates more vulnerabilities to cyber threats, making the protection of intellectual property and operational data critical.

- Legacy system integration: Integrating new technologies with older, existing infrastructure is often complex and requires careful planning and custom solutions.

- Organizational culture: Resistance to change and a lack of stakeholder buy-in can slow or prevent adoption.

A comprehensive NetSuite Assessment can be an invaluable first step toward overcoming these challenges.

How does advanced manufacturing contribute to sustainability?

Sustainability is often an inherent benefit of advanced manufacturing.

- Reduced material waste: Technologies like additive manufacturing (3D printing) use only the necessary material, drastically cutting waste compared to traditional subtractive methods.

- More efficient energy use: Smart systems optimize processes, predict maintenance, and monitor energy consumption in real-time, leading to significant energy savings.

- Lighter products: Advanced materials and design optimization lead to lighter products, which improves fuel efficiency in sectors like automotive and aerospace.

- Circular economy: Advanced technologies facilitate designing products for recycling, repair, and remanufacturing, enabling a circular model that minimizes waste.

- Enabling green technology: Advanced manufacturing is essential for producing renewable energy technologies like solar panels, wind turbines, and batteries with the required precision and efficiency.

Conclusion

The journey into what is advanced manufacturing reveals a profound shift from isolated, manual labor to an integrated era of technology, data, and intelligent systems. Today, 3D printers create once-impossible parts, AI predicts machine failures, and real-time sensor data optimizes entire operations.

This is today’s reality. Advanced manufacturing creates new, higher-skilled jobs and strengthens national economic security and supply chain resilience. However, challenges like high investment costs, the skills gap, cybersecurity threats, and legacy system integration are real problems.

With over 20 years of experience, we know success requires more than just machinery. It demands an integrated business system to manage complexity, unify data, and provide real-time insights for smart, fast decisions.

This is where we come in. As your NetSuite Optimization Engine, Nuage helps businesses leverage platforms like NetSuite to connect data, automate processes, and gain the visibility needed to thrive. The future of manufacturing is here.

Let us help you build the foundation for your advanced manufacturing journey.