NetSuite inventory optimization: 3 Advanced Steps

Why NetSuite Inventory Optimization Matters Now More Than Ever

NetSuite inventory optimization helps businesses balance supply and demand using real-time data and advanced forecasting. It reduces carrying costs, prevents stockouts, improves cash flow, increases accuracy, and improves decision-making through integrated KPIs.

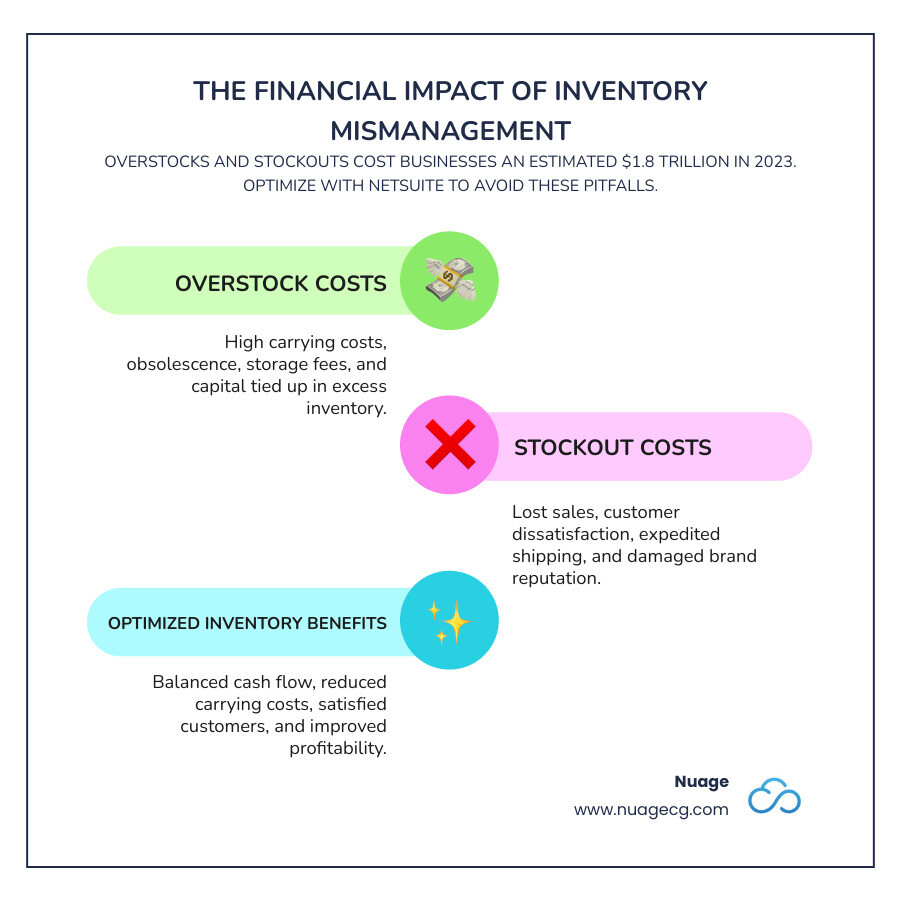

The stakes are high. Research firm IHL estimates that the cost of overstocks and stockouts worldwide neared $1.8 trillion in 2023. Companies are losing money because their inventory systems can’t handle modern supply chain complexity.

Most businesses using NetSuite only scratch the surface of its capabilities. They track quantities but miss the automation and intelligence that transforms inventory from a cost center into a competitive advantage. The gap is enormous: it’s the difference between firefighting stock issues and having a system that anticipates demand, automates reordering, and provides complete visibility.

I’m Louis Balla, and with over 15 years in digital change and supply chain, I’ve helped businesses open up NetSuite’s full potential for inventory optimization. This guide shares the advanced techniques that separate companies merely using NetSuite from those truly optimizing with it.

NetSuite inventory optimization vocab to learn:

The Foundation: Why Inventory Optimization is Critical

Managing inventory today is a complex balancing act. Disconnected data across different systems means sales, warehouse, and purchasing teams are out of sync. Decisions are often based on outdated spreadsheets, leading to costly errors.

Without real-time visibility, you’re flying blind. You might have excess stock in one location while customers face backorders in another. Manual tracking errors, like a simple typo, can cascade into major issues. As Techweez points out, managing inventory levels is a delicate balancing act that requires precision.

This is where a centralized ERP like NetSuite becomes essential. It acts as a single source of truth for your entire operation, providing real-time data accessible to everyone.

What is NetSuite Inventory Optimization?

NetSuite inventory optimization means having the right amount of inventory in the right place at the right time. It’s not just about tracking numbers; it’s about minimizing costs and waste while maximizing sales.

This is achieved through a unified system connecting inventory with sales, purchasing, and accounting. When a sale occurs, inventory levels update instantly. When stock is low, purchase orders can be generated automatically. This real-time visibility across all channels and locations allows for data-driven decisions based on actual demand, not guesswork. Automation handles fulfillment, replenishment, and reporting, freeing your team for more strategic work. You can learn more on the official NetSuite Inventory Management page.

Common Inventory Mistakes NetSuite Helps Avoid

Even smart businesses make costly inventory mistakes. NetSuite inventory optimization helps you sidestep these common pitfalls:

- Overstocking and obsolescence: NetSuite’s forecasting tools use historical data and trends to predict demand more accurately, preventing you from buying too much inventory based on optimistic projections.

- Understocking and lost sales: Automated replenishment and real-time visibility ensure you maintain optimal stock levels, so you don’t lose customers to competitors when you’re out of stock.

- Poor demand forecasting: NetSuite incorporates advanced analytics that factor in seasonality, trends, and promotions for more accurate predictions than simply looking at last year’s numbers.

- Inefficient warehouse utilization: NetSuite’s warehouse management features, including bin management, optimize how you organize and locate inventory, reducing search and picking times.

- Lack of traceability: Lot and serial number tracking provides complete traceability, which is critical for recalls, warranty management, and compliance.

- Manual reconciliation errors: NetSuite’s integrated system automatically updates all records with each transaction, eliminating the manual data entry errors that plague spreadsheet-based systems.

Core Features for NetSuite Inventory Optimization

When people talk about NetSuite inventory optimization, they’re really talking about a powerful suite of interconnected tools working together. It’s not just one magic button—it’s a comprehensive system designed to give you complete control and visibility over your inventory, no matter how complex your operations get.

The beauty of NetSuite is how it brings everything together in one place. You gain real-time visibility across every warehouse, retail store, and third-party logistics partner. The platform handles multi-channel management and automated fulfillment seamlessly, reducing errors and speeding up the order-to-cash cycle. The Item 360 Dashboard acts as a mission control for each product, centralizing KPIs, inventory counts, and automated alerts. Explore more on the Advanced Inventory Management Features and Benefits page.

Demand Planning and Forecasting

Here’s where NetSuite inventory optimization really starts to shine. NetSuite’s demand planning tools analyze historical data, sales forecasts, and seasonality trends. Its predictive analytics engine then generates automated purchase order suggestions to help you maintain optimal stock levels. This data-backed approach dramatically reduces the guesswork that leads to costly overstocks or stockouts, shifting your inventory management from reactive to proactive.

Multi-Location and Multi-Channel Management

NetSuite eliminates the chaos of managing inventory across multiple locations with a centralized view of stock. You get a real-time snapshot of inventory across all warehouses, retail stores, 3PLs, and drop-shippers. The system also enables automated stock transfers between locations to balance inventory. This enterprise-wide inventory availability means your sales team can check stock across the entire network to save a sale, rather than losing a customer.

Advanced Item and Fulfillment Control

True optimization requires granular control. NetSuite provides this through several key features:

- Lot and serial number tracking: Delivers detailed traceability for compliance and recalls, and enables strategies like First Expiring, First Out (FEFO) to minimize waste.

- Matrix items: Simplifies management of products with variations (like size and color). You manage a single parent item, and NetSuite handles all the child SKUs, saving time and reducing errors.

- Bin management: Tracks items to their exact physical location in the warehouse, speeding up picking and packing operations.

- Fill Rate Optimization: Uses intelligent logic to calculate how to fulfill the largest number of complete orders on time when inventory is tight, maximizing customer satisfaction. This is part of the advanced functionality in the NetSuite Applications Suite.

Advanced Strategies for Peak Performance

Getting NetSuite’s inventory features up and running is just the beginning. The real change happens when you optimize these tools for peak performance through strategic data management, smart automation, and a commitment to getting better every day.

At Nuage, we’ve learned that successful NetSuite inventory optimization rests on clean data, engaged users, and continuous refinement. Technology alone isn’t enough; you need accurate information and a team that understands the ‘why’ behind the new processes. A powerful tool for this is NetSuite Smart Count, which allows for continuous inventory verification without freezing operations.

Automating Replenishment with AIM and Dynamic Reorder Points

NetSuite’s Advanced Inventory Management (AIM) transforms replenishment into a proactive, intelligent process. AIM analyzes historical data to automatically calculate optimal reorder points and preferred stock levels. We configure the system to factor in lead time, safety stock levels, and seasonal variations in demand. The NetSuite Applications Suite then suggests or generates purchase orders at precisely the right moment.

This demand-based replenishment approach uses dynamic reorder points that adjust as your business conditions change, ensuring you maintain ideal stock levels without tying up excess capital.

Practical Steps for NetSuite Inventory Optimization

Achieving peak performance with NetSuite inventory optimization requires a thoughtful, structured approach. Here are the practical steps we recommend:

- Define clear KPIs: Know what success looks like before you start. As Gartner emphasizes that clearly defined KPIs are essential for measuring the success of any technology implementation, this is a critical first step.

- Cleanse your item master data: Verify that units of measure, lead times, and ABC classifications are correct. The old adage “garbage in, garbage out” is especially true here.

- Configure cycle counting using ABC analysis: Maintain accuracy without the disruption of full physical counts by counting high-value ‘A’ items more frequently.

- Standardize your workflows: Document how receiving, transfers, and fulfillment should work. Consistency reduces errors and simplifies training.

- Provide comprehensive training: Explain the “why” behind new processes to drive user adoption and turn your team into advocates.

- Refine and monitor: Assign replenishment methods per SKU, set appropriate safety stock, run MRP routinely, monitor inventory turnover, and enforce vendor lead-time accountability.

Leveraging Analytics for Continuous NetSuite Inventory Optimization

The real power of NetSuite is in the insights you gain from analyzing transactions. This is where continuous NetSuite inventory optimization becomes possible.

We help businesses harness inventory turnover reports to understand how quickly products move and aging reports to flag slow-moving or obsolete stock. Sales velocity analysis provides a window into product popularity and helps predict future demand.

With custom dashboards, managers can see inventory health at a glance, enabling proactive adjustments. This creates a continuous feedback loop: monitor, identify, adjust, and measure. Over time, your inventory strategy becomes increasingly refined and effective.

Open uping Business Value: The Benefits of Optimization

When you invest the time and effort into NetSuite inventory optimization, you’re not just tweaking settings in a software system. You’re fundamentally changing how your business operates, and the results show up where it matters most—your bottom line, your team’s productivity, and your customers’ experience.

The benefits are tangible: reduced operational costs from eliminating overstocking and rush orders, and improved cash flow as capital is freed from excess inventory. Improved customer satisfaction follows when products are consistently in stock, and increased productivity comes from automating manual tasks. Finally, the system provides effortless scalability, growing with you as you add products, locations, or channels. NetSuite is built for growth.

Integrating Inventory with Financials for True Oversight

NetSuite’s native integration between inventory and financials provides true business oversight. Every inventory transaction automatically updates the general ledger in real-time. This eliminates tedious month-end reconciliation and the manual errors that distort your financial picture.

NetSuite helps you calculate the true cost of carrying inventory, including storage, insurance, and capital costs. Landed cost tracking is another game-changer, capturing all ancillary expenses like freight and duties. This gives you an accurate picture of product profitability, helping you make smarter pricing and stocking decisions.

The Cloud Advantage: Scalability and Real-Time Access

The fact that NetSuite lives in the cloud isn’t just a technical detail. It’s a strategic advantage that enables:

- Remote access for distributed teams: Your entire team can access the same real-time data from anywhere.

- Real-time data sync across all channels: A sale on your website instantly updates inventory levels for your retail stores and purchasing system.

- Scalability without infrastructure overhead: As your business grows, NetSuite handles the increased load without you needing to invest in servers or IT staff.

- Automatic updates: You always have the latest features and security patches without disruptive, expensive upgrade projects.

- A single platform for growth: As you expand, you activate new modules within the same system, keeping your data unified and processes consistent.

At Nuage, we help businesses configure and optimize NetSuite to transform inventory chaos into a lean, efficient operation. We are your NetSuite Optimization Engine.

Frequently Asked Questions about NetSuite Inventory Optimization

People considering NetSuite inventory optimization usually have similar questions. We’ve answered the most common ones here based on our years of experience helping businesses transform their inventory management.

How much does NetSuite Inventory Management cost?

NetSuite’s core inventory management capabilities are included with the standard NetSuite ERP license. For more complex needs, advanced modules like Advanced Inventory Management (AIM) and Warehouse Management System (WMS) are available as add-ons. Pricing is a subscription model based on your user count, selected modules, and operational complexity. At Nuage, we help you determine the right configuration without overspending on unnecessary features.

How do you implement NetSuite for inventory management?

A successful implementation follows key phases:

- Discovery and Planning: We analyze your current processes and define clear goals and KPIs.

- Configuration and Data Migration: We configure NetSuite to your business rules and migrate your existing data, ensuring its cleanliness.

- Testing: We thoroughly test all inventory workflows to catch issues before they impact your operations.

- Training: We provide comprehensive training so your team understands the ‘why’ behind the new processes, driving user adoption.

- Go-Live and Support: We support you through the launch and provide ongoing assistance for continuous optimization.

Success hinges on clear goals, clean data, and team buy-in. Partnering with an experienced team like Nuage ensures you steer the process successfully.

What is the difference between basic and Advanced Inventory Management (AIM)?

The distinction between basic NetSuite Inventory Management and Advanced Inventory Management (AIM) is like the difference between a calculator and a financial advisor. Both are useful, but one is far more strategic.

- Basic Inventory Management: Included with NetSuite ERP, it provides core functionality for tracking inventory. It answers, “How many do I have and where?” This is often sufficient for businesses with straightforward needs.

- Advanced Inventory Management (AIM): An add-on module that provides sophisticated features for complex supply chains. AIM includes demand-based replenishment, dynamic reorder points, lot and serial number tracking, and multi-location planning. It moves you from reactive tracking to proactive optimization, helping you decide when to order based on intelligent forecasts. For businesses serious about NetSuite inventory optimization, AIM is where the real power lies.

Conclusion: Transform Your Inventory into a Competitive Advantage

The numbers are clear. With inventory mismanagement costing businesses $1.8 trillion globally and a majority of companies scrambling for supply chain visibility, NetSuite inventory optimization is no longer a luxury—it’s essential for survival.

The difference between thriving and merely surviving often comes down to inventory management. Thriving companies use systems to anticipate demand and make data-driven decisions, moving beyond spreadsheets and reactive firefighting.

By leveraging NetSuite’s advanced features—from demand-based replenishment to real-time multi-location visibility—you can achieve reduced operational costs, improved cash flow, and delighted customers. These are the natural outcomes of proper optimization.

Your inventory can be a competitive advantage, not a liability. At Nuage, we’ve spent over 20 years helping businesses with digital change. We know the software is only as good as how you use it. As your NetSuite Optimization Engine, we don’t just sell software; we help you optimize your existing investment to deliver real business value.

Whether you’re starting your NetSuite inventory optimization journey or feel you’re not getting enough from your current setup, we can help. We know the strategies that work in the real world.

Ready to transform your inventory from a cost center into a strategic asset? Explore our NetSuite optimization services to unlock your system’s full potential. Let’s turn a trillion-dollar problem into your competitive edge.