Why Modern Warehouses Need Cloud-Based Inventory Control

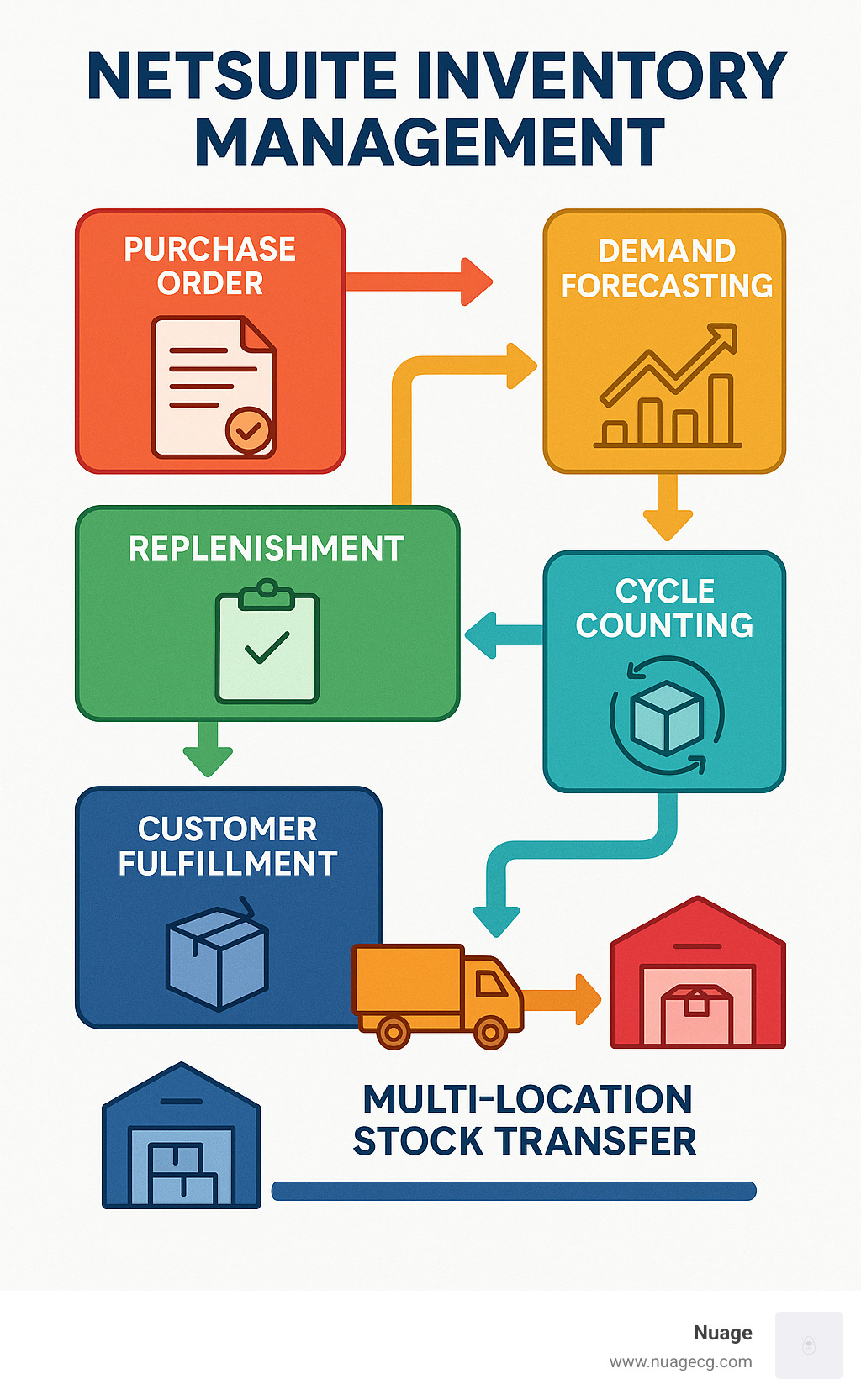

NetSuite inventory management provides real-time visibility across all locations, automates replenishment decisions, and eliminates the manual errors that cost manufacturers millions each year. For businesses managing complex supply chains, it’s the difference between reactive firefighting and proactive optimization.

Key NetSuite Inventory Management Capabilities:

– Real-time tracking across warehouses, 3PLs, and drop-ship locations

– Automated replenishment using demand forecasting and seasonality data

– Multi-location fulfillment with intelligent transfer suggestions

– Complete traceability through lot and serial number tracking

– Cycle counting without operational disruption via Smart Count

– Integrated costing supporting FIFO, LIFO, and weighted average methods

The statistics tell the story: 79% of supply chain leaders have implemented dashboards for end-to-end visibility, while 48% cite warehouse costs as their biggest inflationary challenge. Companies like LovelySkin handled a 300% order increase seamlessly thanks to NetSuite’s smart inventory systems.

Traditional spreadsheet-based inventory creates data silos and leaves manufacturers vulnerable to stockouts, overstocking, and obsolete inventory. NetSuite’s cloud-native approach connects every aspect of your supply chain—from purchase orders to customer fulfillment—in one unified platform.

I’m Louis Balla, and over my 15 years in digital change and supply chain optimization, I’ve seen how NetSuite inventory management transforms warehouse operations from cost centers into competitive advantages. My experience building and installing third-party NetSuite applications gives me deep insight into the real-world challenges manufacturing teams face when scaling their inventory operations.

Basic NetSuite inventory management terms:

– NetSuite ERP implementation

– NetSuite data migration

– NetSuite software optimization

NetSuite Inventory Management: Features That Matter

When you’re running a manufacturing or food & beverage operation, inventory management isn’t just about counting boxes—it’s about keeping cash flowing and operations humming. NetSuite inventory management brings together the features that actually move the needle on profitability, eliminating the daily headaches that come with spreadsheet-based tracking.

The magic happens with real-time visibility across your entire operation. While your old system required manual updates and constant reconciliation, NetSuite’s inventory management automatically captures every transaction as it happens. From the moment a purchase order arrives to when products ship to customers, you see everything in one unified view.

The Item 360 Dashboard becomes your command center, pulling together all the KPIs, stock projections, and alerts you need in one place. Our clients tell us this single feature saves hours of daily reconciliation work that used to eat up their mornings. No more hunting through multiple spreadsheets to figure out what’s really happening with inventory levels.

Smart Count changes the game for cycle counting by letting you count inventory without shutting down operations. The system automatically alerts counters when live transactions happen during counts, keeping everything accurate while your team stays productive. This has been a lifesaver for our food & beverage clients who need to maintain compliance without grinding operations to a halt.

For businesses dealing with regulated products, NetSuite’s traceability capabilities track every lot and serial number with complete audit trails. Whether you’re dealing with FDA requirements in food processing or pharmaceutical manufacturing, the system keeps you compliant without extra paperwork.

Multi-Location Fulfillment & Transfer Orders

Managing inventory across multiple warehouses, 3PLs, and drop-ship vendors gets complicated fast. NetSuite inventory management keeps everything coordinated by showing real-time stock levels at each location while suggesting smart transfer orders to prevent stockouts and reduce obsolete inventory.

The multi-location fulfillment engine acts like having a logistics expert making decisions 24/7. It automatically picks the best shipping location based on your rules—considering shipping costs, available inventory, and delivery times. With warehouse costs being the biggest headache for nearly half of logistics managers today, this intelligent fulfillment directly impacts your bottom line.

Transfer order suggestions use smart analysis to recommend when and where to move stock. If your West Coast warehouse is overflowing while your East Coast facility hits reorder points, the system flags the opportunity to balance things out. It’s like having a crystal ball for inventory optimization.

Inter-company transfers become seamless when you’re managing subsidiaries through NetSuite OneWorld. The system handles all the accounting implications automatically, ensuring proper cost allocation without manual journal entries that eat up your finance team’s time.

We’ve seen manufacturing clients reduce total inventory investment by 15-20% while improving fill rates through better stock allocation. That’s the kind of improvement that makes CFOs smile.

Demand-Based Replenishment & Forecasting

Static reorder points based on gut feelings and outdated formulas are inventory killers. NetSuite inventory management transforms replenishment through demand-based calculations that actually consider seasonality, trends, and real-world demand patterns.

The demand planning module becomes your forecasting powerhouse, analyzing historical sales patterns with trend analysis, seasonal variations and cyclical demand, lead time variability from suppliers, and safety stock requirements based on your service level targets. This algorithmic approach prevents the inventory disasters we’ve seen with manual planning.

One air conditioning manufacturer we worked with avoided a massive winter surplus by incorporating seasonality adjustments that their old spreadsheet system couldn’t handle. The system automatically generates purchase order suggestions when items hit calculated reorder points, streamlining procurement workflows.

Your purchasing managers get alerts with recommended order quantities based on economic order quantity calculations and supplier minimum requirements. For businesses with complex bill-of-materials structures, the system calculates component requirements across all production schedules, ensuring raw material availability without tying up unnecessary cash in inventory.

This intelligent approach to replenishment turns inventory from a necessary evil into a competitive advantage, keeping your cash flowing while ensuring you never disappoint customers with stockouts.

From Visibility to Action: Automation & Optimization

Having real-time visibility into your inventory is powerful, but it’s only half the battle. The magic happens when NetSuite inventory management turns that visibility into automated actions that keep your operations running smoothly without constant manual intervention.

Think about it this way: knowing you’re running low on a critical component is helpful, but having the system automatically generate a purchase order based on your supplier lead times and demand forecasts? That’s where you start saving real money and avoiding costly stockouts.

Barcode and RFID integration transforms how your team handles inventory transactions. Instead of manually typing item numbers and quantities (and dealing with the inevitable typos), workers simply scan items during receiving, picking, and shipping. NetSuite supports both passive RFID tags with 40-foot read ranges for standard tracking and active tags extending to 300 feet for automated inventory monitoring throughout larger facilities.

Bin management takes location tracking to the next level. Rather than having workers hunt through warehouses looking for items, the system guides them to specific bin locations for both picking and putaway operations. This granular tracking works seamlessly with serialized and lot-numbered items, ensuring complete traceability for regulated industries.

The real game-changer is workflow automation that handles repetitive tasks without human intervention. The system can automatically generate purchase orders when items hit reorder points, trigger cycle counts based on transaction volume, send alerts for slow-moving inventory, and adjust safety stock levels based on demand patterns.

For our food and beverage clients, these automated workflows have been particularly valuable. NetSuite’s inventory control capabilities include quality management features that support inspection processes and quarantine procedures—essential for maintaining FDA compliance without slowing down operations.

Inventory Costing & Cash-Flow Impact

Here’s where NetSuite inventory management really impacts your bottom line. Accurate inventory costing isn’t just an accounting exercise—it directly affects your gross margins and cash flow decisions.

NetSuite supports multiple costing methods to match your business needs. FIFO (First-In, First-Out) assumes your oldest inventory sells first, giving you current market values for remaining stock. This works great for businesses with perishable products or rapidly changing costs. LIFO (Last-In, First-Out) does the opposite, matching current costs against current revenues—something many manufacturers prefer during inflationary periods.

Weighted average costing smooths out cost fluctuations by calculating average costs across all inventory receipts. This approach works well for commodity-like products with stable pricing. For manufacturers who need detailed cost control, standard costing uses predetermined costs for planning and variance analysis.

Landed cost calculations capture the true cost of inventory by including shipping, customs duties, handling fees, and other acquisition costs. This comprehensive approach enables accurate margin analysis and helps you make informed pricing decisions.

| Manual Spreadsheet Approach | NetSuite Automation |

|---|---|

| Daily manual counts required | Automated cycle counting |

| Email-based report distribution | Real-time dashboard access |

| Manual reconciliation of orders/shipments | Automated transaction processing |

| Error-prone data entry | Barcode/RFID integration |

| Limited cost method support | Multiple costing methods |

| No real-time visibility | Company-wide real-time data |

The system automatically adjusts inventory values when purchase orders are received, eliminating manual journal entries while maintaining complete audit trails for financial compliance. This automation prevents the month-end scrambles we’ve seen with manual systems, where accounting teams spend days reconciling inventory transactions.

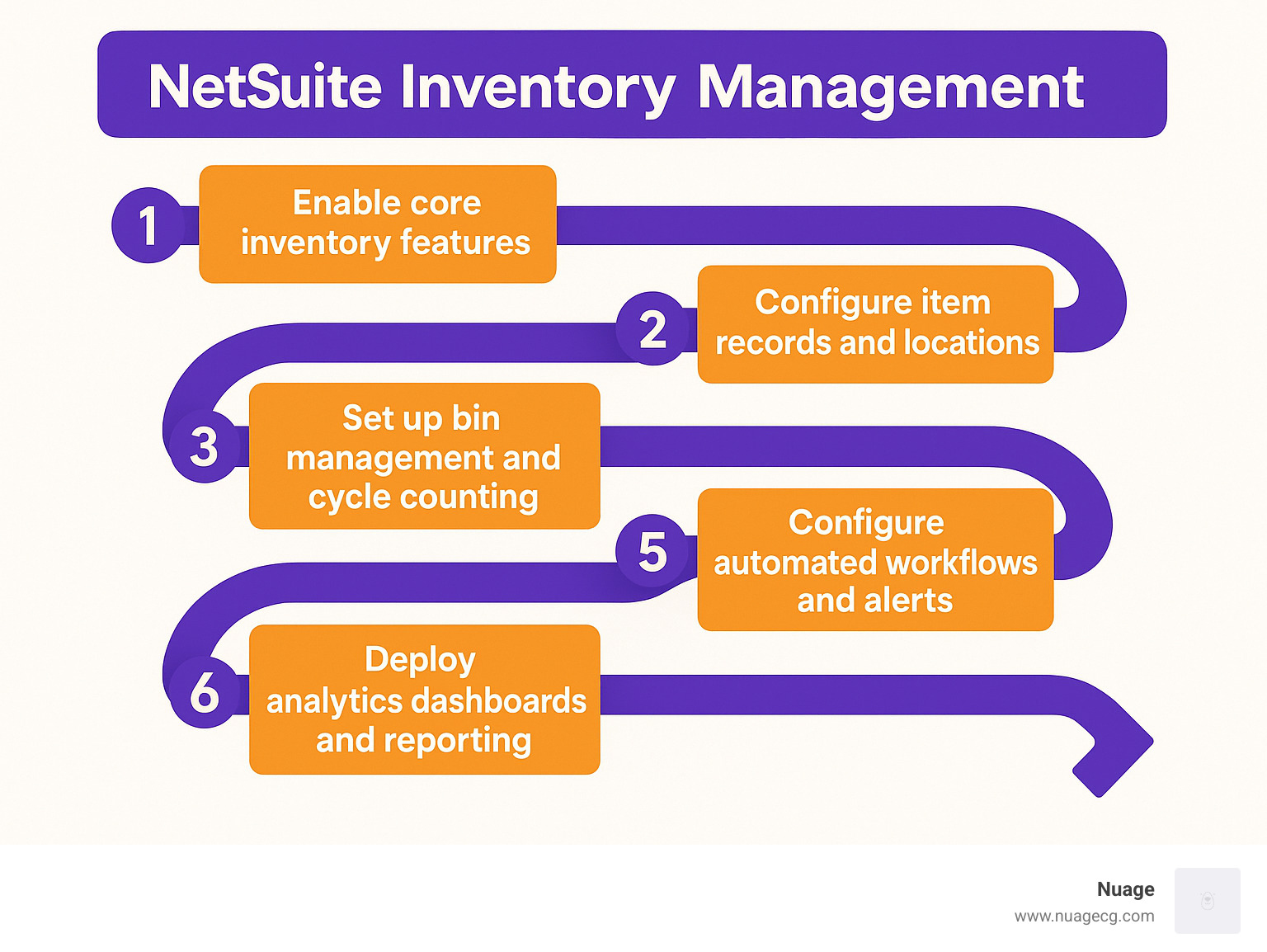

Setting Up NetSuite Inventory Management for Success

Getting NetSuite inventory management up and running smoothly isn’t rocket science, but it does require some thoughtful planning. After helping hundreds of manufacturers and food companies through this process over the past 20 years, we’ve learned that the secret sauce is taking it step by step and getting the foundation right from day one.

Your journey starts in the Setup menu under Company > Enable Features. Think of this as flipping the light switches in your new digital warehouse. You’ll want to turn on Multi-Location Inventory if you’re tracking stock across different facilities, Bin Management for those detailed location controls, and Advanced Bin/Numbered Inventory Management when you need lot and serial tracking. Don’t forget Inventory Count for cycle counting and Inventory Status for handling quarantine situations.

Here’s where many companies stumble: they try to configure everything at once. Instead, start with your top 20% of items—your highest-velocity products that generate the most revenue. Get their item records dialed in perfectly with the right units of measure, costing methods, and replenishment settings. Once you’ve validated that these work smoothly, expanding to your full catalog becomes much easier.

Location setup is where the rubber meets the road. Your warehouse and bin structure needs to mirror how your team actually works, not some theoretical ideal. We’ve seen too many implementations fail because someone designed a beautiful location hierarchy that made no sense to the people picking orders every day.

The real magic happens when you get your inventory dashboards configured properly. SuiteAnalytics transforms all that transaction data into actionable insights without requiring a computer science degree. Your team can finally see what’s happening in real-time instead of waiting for yesterday’s reports.

Best Practices & Compliance

When you’re dealing with regulated industries, NetSuite inventory management becomes your compliance safety net. We work with a lot of food and beverage companies who need to sleep well at night knowing they can trace any ingredient back to its source in minutes, not days.

The FDA and FSMA requirements that keep food safety managers up at night are built right into the lot tracking functionality. Forward and backward traceability isn’t just a checkbox—it’s comprehensive documentation that can save your company’s reputation when recalls happen. And they do happen, even to the best companies.

Expiration date tracking goes beyond basic compliance. The system helps you implement first-expiring-first-out strategies that minimize waste and keep your customers happy. Nobody wants to receive products that expire next week when they ordered them for next month’s production run.

Quality management workflows turn inspection processes from paperwork nightmares into streamlined digital workflows. Whether you’re managing quarantine procedures or tracking certificates of analysis, the system handles the documentation while your team focuses on actually ensuring quality. This proves invaluable for ISO 9001, SQF, or BRC certifications where documentation gaps can derail entire audits.

Every inventory transaction gets logged with complete audit trails—who did what, when they did it, and why. This isn’t just about satisfying auditors (though it definitely does that). It’s about having the transparency to actually understand what’s happening in your operation and make informed decisions about improvements.

Sustainability reporting has moved from nice-to-have to must-have for many of our clients. The system tracks inventory waste, obsolescence, and environmental impact metrics that increasingly influence both customer purchasing decisions and regulatory requirements. Your sustainability story becomes data-driven rather than guesswork.

Product Roundup & Licensing Snapshot

When evaluating NetSuite inventory management for your business, understanding the licensing structure helps you build the right solution without overpaying for features you don’t need yet. Over our 20 years of ERP implementations, we’ve learned that smart licensing decisions can save thousands while ensuring room to grow.

The core NetSuite license provides solid inventory fundamentals that work well for most small to mid-sized manufacturers. You get multi-location tracking, standard costing methods, and basic reporting—everything needed to move beyond spreadsheets into real-time inventory control. Many of our clients start here and expand as their operations grow.

Advanced Inventory Management becomes essential when you need lot and serial number tracking. Food and beverage companies especially benefit from the improved bin management and sophisticated cycle counting capabilities. The traceability features alone justify the investment for any business facing regulatory requirements or customer demands for product history.

For high-volume operations, Warehouse Management System (WMS) integration transforms NetSuite into a comprehensive warehouse execution platform. The advanced picking, putaway, and labor management capabilities handle the complexity that comes with scaling operations. We’ve seen this add-on eliminate bottlenecks that were choking growth for expanding manufacturers.

Smart Count deserves special mention because it solves one of the biggest headaches in inventory management—cycle counting without stopping operations. The system automatically alerts counters when live transactions affect items being counted, maintaining accuracy while preserving productivity. The labor savings and improved accuracy typically pay for this feature within months.

SuiteAnalytics Connect opens up advanced reporting and dashboard capabilities that turn data into actionable insights. Custom KPI tracking and sophisticated inventory analysis help you spot trends and optimize performance. This becomes crucial as your business grows and requires deeper visibility into inventory patterns.

Sandbox environments cost a fraction of your total licensing fees but provide invaluable testing space for configuration changes and user training. We always recommend sandbox access for businesses planning customizations or wanting to test new processes safely.

NetSuite’s comprehensive inventory features work seamlessly with other modules, creating workflows that eliminate the disconnects plaguing multi-system environments. The integration with NetSuite order management creates particularly smooth processes from customer orders through fulfillment.

At Nuage, we help you steer these options to build the right solution for your current needs while planning for future growth. Our experience with both NetSuite and other ERP platforms means we recommend solutions, not just sell software.

Frequently Asked Questions about NetSuite Inventory Management

How does NetSuite prevent stockouts and overstocking?

The biggest nightmare for any warehouse manager? Running out of your best-selling product while sitting on mountains of slow-moving inventory. NetSuite inventory management tackles both problems with smart automation that learns from your business patterns.

For stockout prevention, the system goes way beyond simple reorder points. It analyzes your historical sales data, spots seasonal trends, and factors in how long your suppliers actually take to deliver (not just what they promise). When inventory hits the calculated reorder point, NetSuite automatically generates purchase order suggestions—no more relying on gut feelings or sticky note reminders.

The real magic happens with overstocking prevention. NetSuite identifies when you have excess inventory at one location while another location is running low. The system suggests intelligent transfer orders to move stock where it’s needed most. This redistribution saves money on both storage costs and rush shipping fees.

Safety stock calculations consider how unpredictable your demand really is. If your sales fluctuate wildly, NetSuite builds in more buffer inventory. If demand is steady and predictable, it keeps safety stock lean. The system also generates aging reports that flag slow-moving inventory before it becomes a write-off problem.

Which costing methods are supported out-of-the-box?

Getting inventory costing wrong can wreck your margins and confuse your accountants. Fortunately, NetSuite inventory management supports all the major costing methods without requiring expensive customizations or third-party add-ons.

FIFO (First-In, First-Out) works perfectly for businesses dealing with perishable products or rapidly changing costs. Your oldest inventory gets sold first, keeping your remaining stock valued at current market prices. Food and beverage companies especially appreciate this method for managing expiration dates.

LIFO (Last-In, First-Out) assumes your newest inventory sells first, which matches current costs against current revenues. Some manufacturers prefer this approach during inflationary periods because it provides better cost matching.

Weighted Average smooths out cost fluctuations by calculating average costs across all inventory receipts. This method works well for businesses with stable, commodity-like products where individual purchase costs don’t matter as much.

Standard Costing uses predetermined costs for planning and variance analysis. Manufacturing companies love this for budgeting and identifying when actual costs deviate from expectations.

The system also handles landed cost calculations automatically, including shipping fees, customs duties, and handling charges in your true inventory costs. This comprehensive approach ensures your margin analysis reflects reality, not just the invoice price from suppliers.

What steps are required to integrate barcoding or RFID?

Setting up barcode scanning with NetSuite inventory management is surprisingly straightforward. You’ll first enable the barcode feature in your NetSuite setup, then configure your item records with barcode values. The system supports standard barcode formats and can even generate barcodes automatically based on your item numbers.

Most businesses start with basic barcode scanning for receiving and shipping, then expand to cycle counting and picking operations. The beauty of NetSuite’s approach is that barcoded transactions automatically update your inventory records—no separate data imports or manual reconciliation required.

RFID integration involves a few more steps but delivers powerful automation benefits. You’ll need to enable Advanced Bin/Numbered Inventory Management first, then work with certified NetSuite partners to configure your RFID hardware. The setup includes programming automated workflows that read RFID tags and update inventory records in real-time.

Staff training for both technologies is typically minimal since the scanning integrates seamlessly with existing NetSuite workflows. Workers continue using familiar transaction screens—they just scan instead of typing item numbers. The accuracy improvements and time savings usually justify the investment within the first few months of implementation.

Both barcode and RFID systems work especially well with NetSuite’s bin management capabilities, providing precise location tracking throughout your warehouse operations.

Conclusion

When you’re dealing with inventory challenges that keep you up at night—stockouts, overstocking, or simply not knowing what you have where—NetSuite inventory management offers the comprehensive solution that transforms those headaches into competitive advantages.

The real magic happens when everything connects. Real-time visibility across all your locations, automated replenishment that actually understands your demand patterns, and traceability that keeps regulators happy while streamlining your operations. It’s not just about having better software; it’s about having inventory systems that work as hard as you do.

At Nuage, we’ve spent over 20 years in the trenches with manufacturers and food & beverage companies, helping them steer the complex world of ERP systems. What sets us apart? We’re not here to sell you software—we’re here to solve your problems. Our expertise with both NetSuite and means we recommend the right solution for your specific situation, not whatever happens to be on sale.

The numbers tell the story our clients live every day. Most see 15-20% reductions in total inventory investment while actually improving their customer service levels. That’s the power of having systems that eliminate guesswork and replace it with data-driven decisions.

Whether you’re wrestling with complex manufacturing BOMs, staying ahead of FDA compliance, or coordinating inventory across multiple distribution centers, NetSuite inventory management provides the foundation you need for sustainable growth. No more spreadsheet nightmares, no more manual reconciliations, no more wondering if you can fulfill that big order.

Your warehouse operations deserve better than reactive firefighting. They deserve to be the profit driver they can become with the right systems in place.

Ready to see what’s possible? Learn more about NetSuite ERP and find how our digital change expertise can turn your inventory challenges into your biggest competitive advantage.