Why Your Business Needs Strategic Inventory Management

Every growing business faces the same inventory nightmare: too much of what customers don’t want and not enough of what they do. Stockouts kill sales, excess inventory kills cash flow, and manual spreadsheets kill productivity.

NetSuite demand planning solves this by helping businesses predict future inventory needs based on historical demand, seasonality, and sales forecasts. The result is optimized stock levels and a more efficient supply chain.

As Tomei Thomas, CEO of Beekman 1802, puts it: “Demand planning is a big aspect of what we do. It really comes from looking at historical data. NetSuite allows us to understand the historical velocity of any one product.”

The cost of poor planning is massive. It locks up working capital in dead stock while customers abandon orders for out-of-stock items. Teams waste hours updating disconnected spreadsheets that are instantly outdated.

NetSuite’s demand planning module transforms this chaos into a competitive advantage. It automates data collection and provides accurate forecasts that drive smarter inventory decisions, helping companies open up millions in working capital while eliminating stockouts.

Key NetSuite Demand Planning Capabilities:

- Four projection methods: Linear regression, moving average, seasonal average, and sales forecast

- Multi-location inventory management with real-time visibility

- Automated supply plan generation from demand forecasts

- Integration with sales, procurement, and production

- Cash flow optimization by reducing excess inventory

- Exception management with real-time alerts

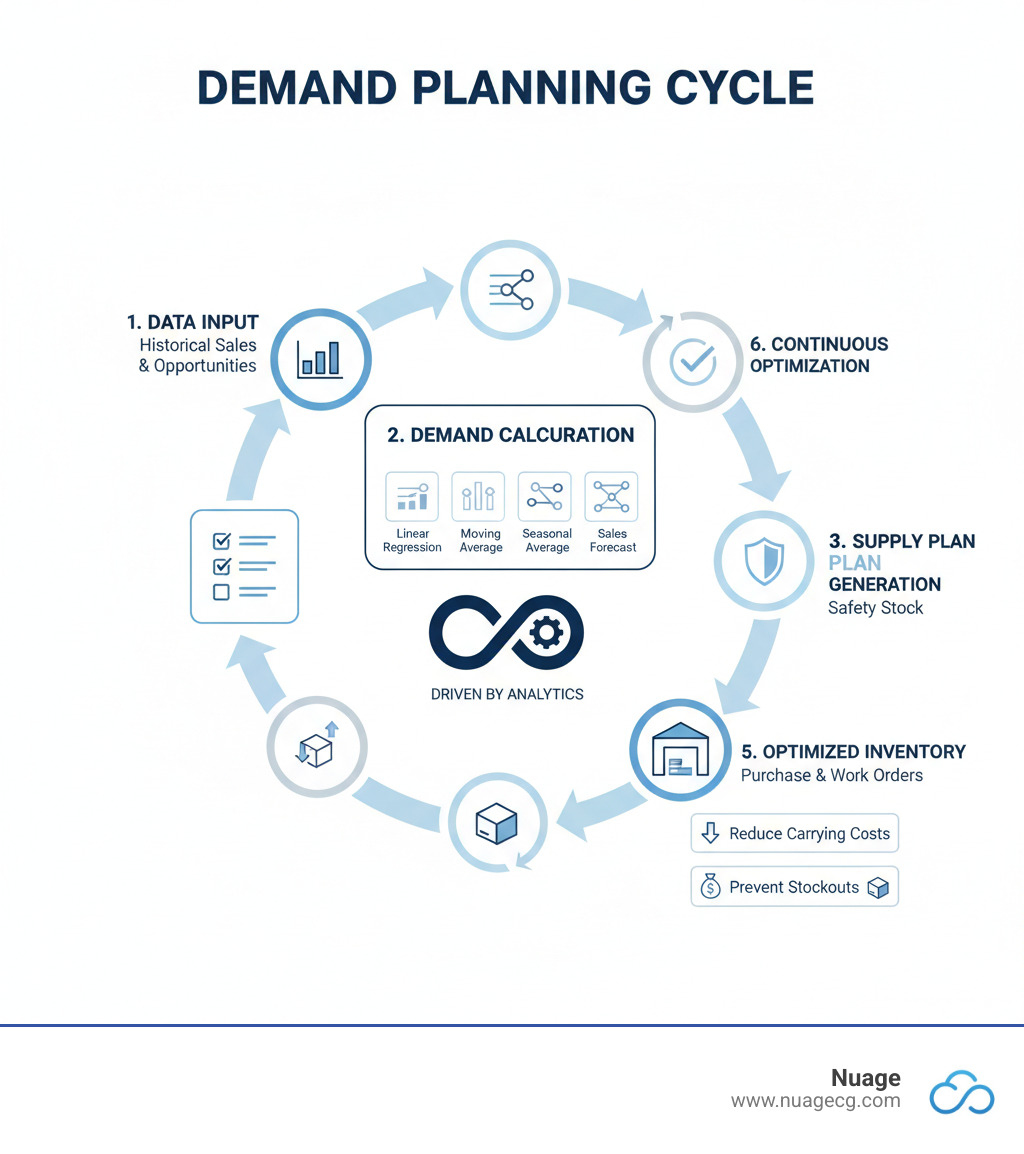

What is Demand Planning and How Does It Work in NetSuite?

Demand planning is the process of predicting what customers will want, when they’ll want it, and how much they’ll need. It’s a cross-functional effort that brings together sales, marketing, operations, and finance to create a unified strategy. This alignment improves supply chain efficiency, boosts financial performance, and optimizes working capital.

For a deeper dive into the fundamentals, check out this insightful video:

What is Demand Planning? (Video)

Instead of juggling disconnected spreadsheets, NetSuite demand planning automatically collects data from your entire operation. Inventory levels, sales forecasts, and procurement schedules are integrated into a single view. This helps you reduce excess inventory and avoid stockouts that send customers to your competitors.

The Difference Between Demand Planning and Demand Forecasting

While related, forecasting and planning are distinct processes.

- Demand Forecasting: This is the analytical process of using historical data and statistical models to predict future customer demand. It answers the question, “What will customers want?”

- Demand Planning: This is the strategic process of using those forecasts to make decisions. It answers the question, “How will we meet that demand?” This involves resource allocation, production scheduling, and procurement decisions.

NetSuite’s integrated platform makes this connection seamless. Forecasts automatically feed into demand plans, which then trigger supply plans, keeping your operation aligned with customer needs.

Core Benefits for Your Business

Implementing NetSuite demand planning delivers a cascade of benefits that directly impact your bottom line:

- Increased inventory turns: Move inventory efficiently based on actual sales patterns, improving cash flow.

- Optimized inventory levels: Order precisely what you need, when you need it, which dramatically reduces overhead costs from storage and obsolescence.

- Improved profitability and ROI: Have adequate stock to fill orders without carrying excess that requires discounting.

- Improved customer satisfaction: Ensure products are available when customers want them, building loyalty through reliable delivery.

By changing inventory management into a strategic advantage, you can achieve significant operational improvements. To see how other businesses have succeeded, read our customer stories.

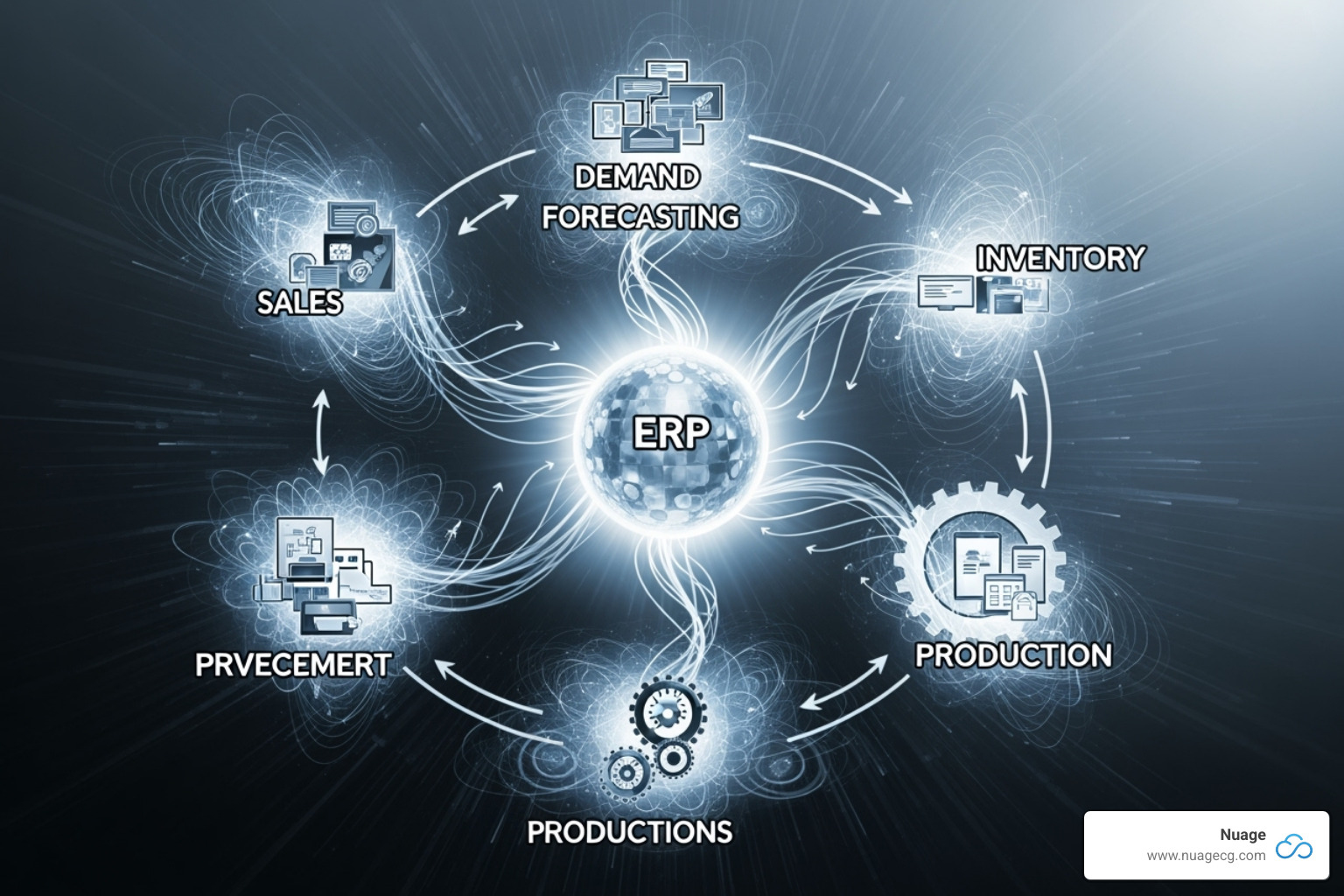

Key Features of NetSuite Demand Planning

NetSuite demand planning replaces spreadsheets and guesswork with a single, integrated ERP platform. Because it’s built into NetSuite’s cloud system, your sales data, inventory levels, and financials are automatically connected and always current. The platform collects and analyzes information in real-time, with customizable dashboards for each role, from sales managers to warehouse staff.

For complete technical details, see the Official NetSuite Demand Planning Software Page.

Forecasting Methods to Improve Accuracy

NetSuite provides four projection methods to improve forecast accuracy for different product types:

- Linear Regression: Projects future sales based on a consistent, predictable growth trend. Ideal for established products.

- Moving Average: Smooths out short-term fluctuations by calculating an average over a set number of past periods, revealing underlying demand trends.

- Seasonal Average: Uses historical data from specific times of year to forecast demand for products with predictable seasonal patterns, like winter coats or summer goods.

- Sales Forecast: Incorporates your current sales pipeline—including open opportunities, quotes, and sales orders—for a forecast based on real-time sales activity.

These methods combine historical data with real-time pipeline information for forecasts that reflect what’s actually happening in your business.

Multi-Location Inventory Management

NetSuite demand planning simplifies inventory management across multiple warehouses or retail stores. Key capabilities include:

- Real-time visibility: Get an instant, accurate view of stock levels across all locations, eliminating the guesswork of manual checks.

- Automated inter-location transfers: The system can automatically create transfer orders to move stock from a location with a surplus to one that is running low.

- Intelligent supply allocation: Prioritize which orders and locations get fulfilled first during a shortage, ensuring your most important customers are served.

This comprehensive approach ensures products are available when and where customers need them. To understand how these features fit into the broader system, Learn the basics with our NetSuite 101 guide.

How NetSuite Demand Planning Manages Cash Flow

Poor inventory planning is a silent cash killer. NetSuite demand planning addresses this by:

- Minimizing excess stock: Accurate forecasts prevent you from ordering products that will sit unsold, freeing up cash.

- Reducing carrying costs: By optimizing inventory levels, you lower expenses for warehousing, insurance, and obsolescence, which can cost 20-30% of your inventory’s value annually.

- Avoiding unnecessary preordering: Clear visibility into future needs allows you to order materials with confidence, preventing the cash squeeze from paying for inventory too early.

- Aligning procurement with demand: Every purchase order is based on real demand signals, creating a just-in-time approach that keeps cash working efficiently.

The result is more working capital available for growth, marketing, and other strategic initiatives.

A Practical Guide to Implementing and Using NetSuite

Getting started with NetSuite demand planning is a step-by-step process. With over 20 years of experience in digital change, our team at Nuage has learned that a proper setup is the foundation for success. Here’s a high-level look at the process.

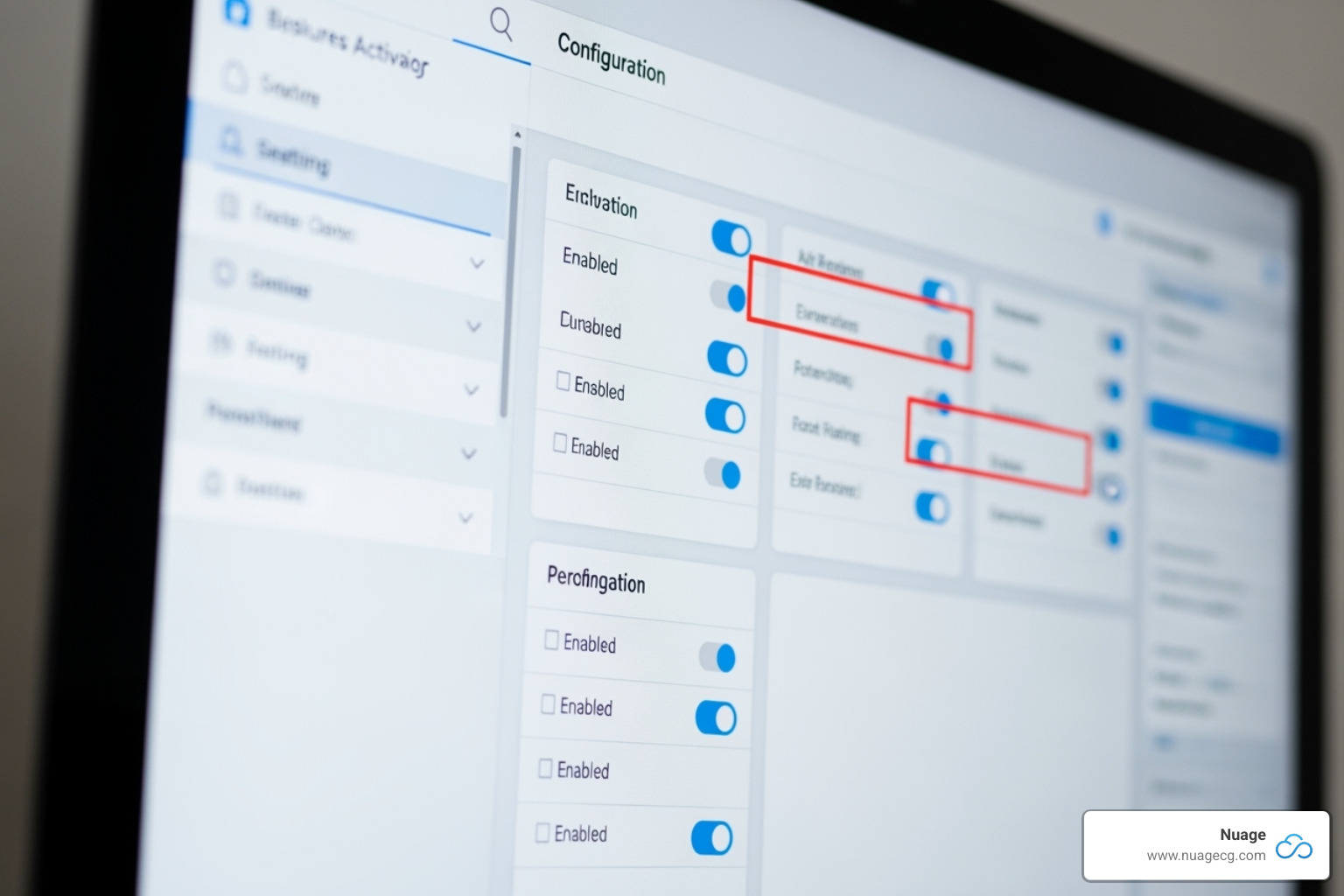

Setting Up and Configuring the Module

Proper configuration ensures NetSuite works for your specific business needs.

- Enable Features: In

Setup > Company > Enable Features, turn on ‘Demand Planning,’ ‘Advanced Inventory Management,’ and ‘Work Orders’ (for assembly items) under the Items & Inventory subtab. - Set Preferences: Under

Setup > Accounting > Preferences > Inventory Management Preferences, choose whether to base demand calculations on ‘Orders’ or ‘Actual Sales’ to define how NetSuite views demand. - Configure Item Records: For each item, set a Replenishment Method (e.g., Reorder Point for steady demand, Time Phased for seasonal items). Use the ‘Alternate Source Item’ feature to forecast new products based on similar existing ones.

- Set Time Fences: On item records, define ‘Demand Time Fence’ and ‘Planning Time Fence’ values to create buffers that prevent last-minute changes from disrupting your plans.

For detailed instructions, refer to the official setup documentation.

Integration with Your Supply Chain

NetSuite demand planning connects every part of your supply chain for a unified operation.

- Inventory Management: Demand plans are tied to real-time stock levels across all locations.

- Procurement: NetSuite automatically suggests purchase orders based on demand plans, giving your team clear guidance on what and when to buy.

- Production Control: For manufacturers, NetSuite creates work orders for assembly items and plans for all necessary raw materials, preventing production delays.

- Sales Data: A Salesforce NetSuite Connector can pull sales pipeline data directly into NetSuite, making forecasts more accurate.

Best Practices for NetSuite Demand Planning

To get the most out of the tool, follow these best practices:

- Make it a continuous process: Weave demand planning into daily operations rather than treating it as a monthly task.

- Standardize data inputs: Clean data is the foundation of accurate forecasting. Remove outliers and anomalies.

- Segment your products: Group items by demand patterns, financial impact, and supplier reliability to apply the right planning strategy to each.

- Foster stakeholder collaboration: Use NetSuite’s role-based dashboards to give sales, marketing, operations, and finance access to the same real-time data.

- Regularly update demand plans: Keep plans current with market realities. Monthly updates are a good start, but volatile products may need more frequent attention.

- Leverage alternate source items: For new products without sales history, base forecasts on a similar, existing item.

From Manual Chaos to Automated Control

Many businesses still rely on a maze of spreadsheets for demand planning, a process that’s prone to error, wastes time, and costs money. This manual chaos leads to reactive decisions based on outdated data and gut feelings.

At Nuage, we’ve helped countless companies move from this scramble to the proactive control offered by integrated ERP solutions like NetSuite. The change is immediate and impactful.

Common Challenges Solved by NetSuite

Manual inventory management creates several profit-killing challenges that NetSuite demand planning directly solves:

- Obsolete Inventory: NetSuite’s data-driven forecasting ensures you stock what sells, not what you guess might sell, preventing warehouses from filling with products nobody wants.

- Lost Sales from Stockouts: By accurately predicting demand spikes, NetSuite helps keep your best-selling items in stock, turning missed opportunities into sales.

- High Overhead Costs: Right-sizing your inventory levels eliminates waste from excess storage, insurance, and capital costs, freeing up cash for growth.

- Production Delays: NetSuite coordinates material availability with production schedules, ensuring your manufacturing lines keep running without costly shutdowns.

- Data Silos: An integrated platform gives all departments—sales, purchasing, and operations—access to the same real-time data, ending the “which spreadsheet is right?” debate.

NetSuite vs. Manual Spreadsheet Planning

The difference between using spreadsheets and NetSuite demand planning is stark. While spreadsheets may seem free, their hidden costs in errors, inefficiency, and lost sales add up quickly.

| Feature | Manual/Spreadsheet Planning | NetSuite Demand Planning |

|---|---|---|

| Accuracy | Prone to human error, limited by manual data entry, outdated data. | High accuracy with statistical models, integrated real-time data, and automated calculations. |

| Efficiency | Time-consuming, labor-intensive, repetitive manual updates. | Highly automated, streamlines data collection and analysis, significant time savings. |

| Scalability | Difficult to scale with business growth, complex as product lines expand. | Scales effortlessly with business growth, handles vast amounts of data and items. |

| Real-time Data | Data quickly becomes outdated, leads to reactive decisions. | Provides real-time visibility across all modules, enables proactive decision-making. |

| Collaboration | Challenging with version control issues, email-based sharing. | Centralized platform, role-based access, fosters cross-departmental collaboration. |

NetSuite shifts your approach from reactive firefighting to strategic planning. Instead of constantly playing catch-up, you stay ahead of demand, working from a single source of truth. This move from manual chaos to automated control allows you to focus on growing your business and serving your customers.

Frequently Asked Questions about NetSuite Demand Planning

Here are answers to some of the most common questions we hear from businesses exploring NetSuite demand planning.

What are the typical costs associated with NetSuite Demand Planning?

NetSuite demand planning is an add-on module within NetSuite’s subscription model. The investment includes:

- Annual License Fee: Covers the core NetSuite platform and your chosen modules.

- Number of Users: The subscription cost scales with the number of users who need access.

- One-Time Implementation Fee: This covers the essential setup, configuration, data migration, and training to ensure a smooth transition.

While pricing varies, the ROI from optimized inventory, reduced carrying costs, and increased sales often means the investment pays for itself within the first year. For a detailed discussion custom to your business, we encourage you to Explore NetSuite Pricing.

How does NetSuite handle seasonal or fluctuating demand?

NetSuite excels at managing seasonality. Its Seasonal Average projection method analyzes historical data to identify and predict recurring demand patterns, whether they occur annually, quarterly, or monthly. The system automatically adjusts forecasts for these peaks and troughs, ensuring stock is available during high-demand periods without overstocking during slow times. When unexpected market changes occur, NetSuite updates forecasts and sends alerts, allowing you to react quickly.

Can I import existing demand data into NetSuite?

Yes, you can bring your historical data into NetSuite without starting from scratch. NetSuite provides several flexible options:

- CSV Import: Ideal for bulk importing historical sales data, forecasts, and demand patterns from spreadsheets.

- Import Assistant: A guided, step-by-step tool that validates your data and ensures it’s mapped correctly within the system.

- Manual Entry: For smaller datasets or specific adjustments, you can enter data directly through the NetSuite interface.

- SOAP Web Services: For complex integrations, this allows for programmatic data transfer from other systems, such as specialized forecasting tools or a CRM.

Future-Proof Your Inventory with Expert Guidance

Moving from manual spreadsheets to the automated precision of NetSuite demand planning transforms inventory management from a reactive chore into a proactive strategic advantage. By anticipating customer needs, you can optimize cash flow, reduce costs, and deliver consistently excellent service.

The benefits are clear: increased inventory turns, lower carrying costs, improved profitability, and higher customer satisfaction. These are the building blocks of supply chain excellence that separate industry leaders from the competition.

At Nuage, our two decades of digital change experience have shown us what works. We don’t just implement software; we partner with you to find the right solutions for your unique challenges. As your NetSuite Optimization Engine, we ignite confidence in the platform across your organization.

Your inventory strategy can be a competitive weapon. With NetSuite demand planning and the right partner, you can drive growth and build sustainable success.

Ready to take control of your inventory future? We’re here to guide you.

Take the next step with a NetSuite Assessment to understand how NetSuite can transform your specific situation.

Explore our NetSuite Solutions to see how we tailor NetSuite’s capabilities to meet your unique business needs.

Last Updated: January 3, 2026

Looking for help optimizing your NetSuite? Contact our team for a free consultation.