Why Manufacturing Leaders Turn to NetSuite Advanced Manufacturing

The NetSuite Advanced Manufacturing user guide is your roadmap to changing disconnected production systems into a unified, real-time manufacturing operation. Here’s what you need to know:

Quick Access to NetSuite Advanced Manufacturing Resources:

- Official User Guide: Available in NetSuite Help Center under Manufacturing Guides section

- Key Documentation: Covers Administration Settings, Production Planning, and Shop Floor Management

- Prerequisites: NetSuite ERP subscription with Work Orders & Assemblies and WIP & Routings modules

- Installation: Advanced Manufacturing SuiteApp extends your existing NetSuite manufacturing capabilities

- Support: Requires collaboration with NetSuite Professional Services for optimal setup

Manufacturing is a high-stakes balancing act. Raw materials, production schedules, supply chains, and customer demands all need to move in sync – and if one piece falls out of place, the ripple effects can be costly.

Most manufacturers today rely on disconnected systems that create data silos, making it nearly impossible to get real-time insights into production performance. When you can’t see what’s happening on your shop floor in real-time, you’re essentially flying blind.

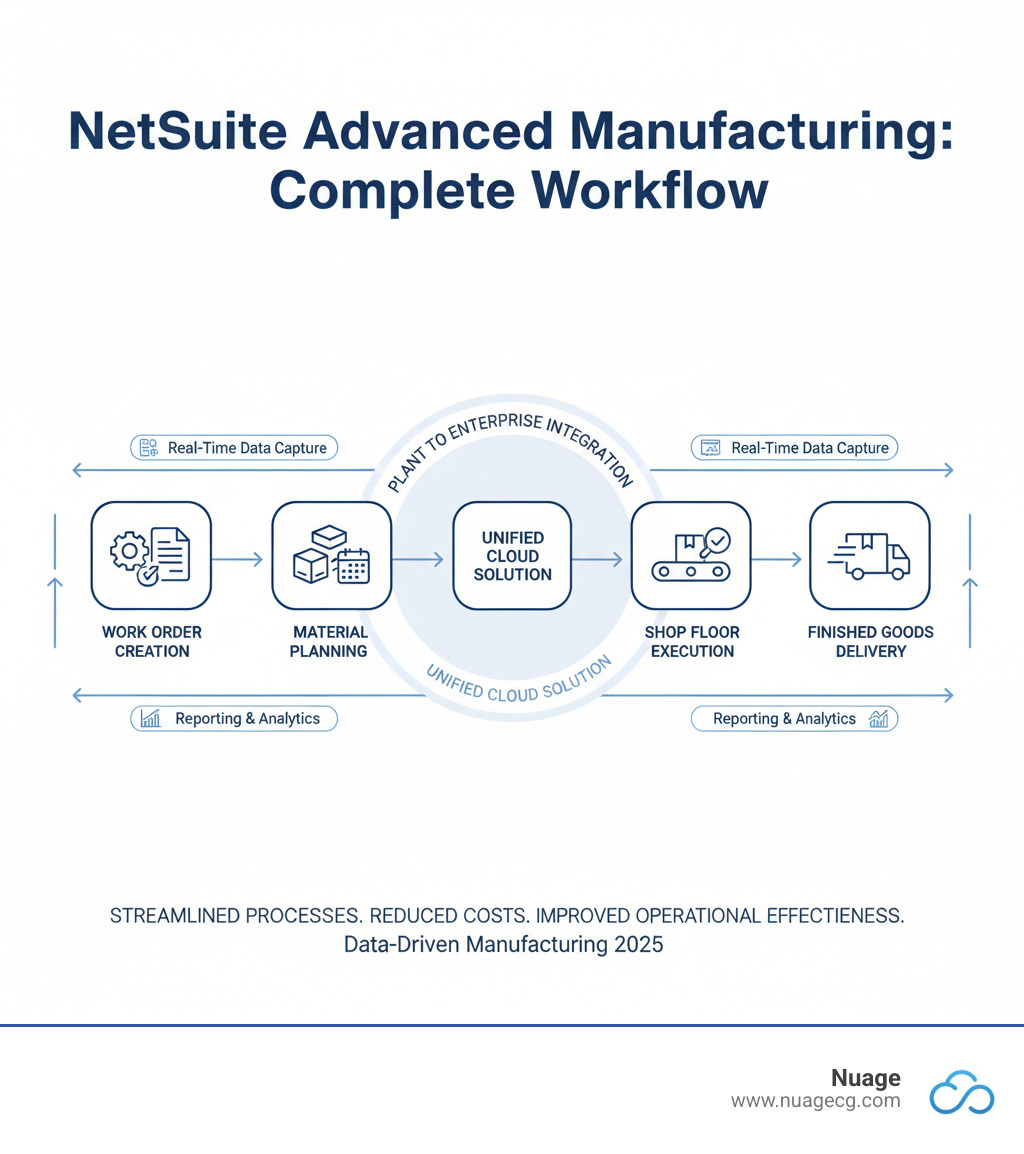

NetSuite Advanced Manufacturing delivers a single integrated cloud solution that replaces these disconnected systems. It extends your existing NetSuite manufacturing capabilities with advanced planning, finite capacity scheduling, and comprehensive shop floor control.

The platform helps manufacturers streamline production processes, reduce costs, and improve operational effectiveness by providing one version of the truth across your entire operation. From work order creation to finished goods, everything connects seamlessly.

I’m Louis Balla, CRO and partner at Nuage, with over 15 years of experience in digital change and supply chain optimization. Having overseen the building and installation of third-party apps for NetSuite, I understand the challenges teams face when navigating the NetSuite Advanced Manufacturing user guide and implementing these powerful manufacturing capabilities.

What is NetSuite Advanced Manufacturing?

Think of NetSuite Advanced Manufacturing as the missing piece that transforms your existing NetSuite ERP into a complete manufacturing powerhouse. Rather than juggling multiple disconnected systems – one for inventory, another for scheduling, and yet another for production tracking – this unified cloud solution brings everything together under one roof.

Most manufacturers we work with come to us frustrated by data silos. Their inventory system doesn’t talk to their production scheduler, which doesn’t sync with their financial reports. It’s like trying to conduct an orchestra where half the musicians can’t hear the conductor. NetSuite Advanced Manufacturing solves this by creating real-time connectivity throughout your entire operation.

The beauty lies in its Plant to Enterprise (P2E) integration. Your shop floor data flows seamlessly to executive dashboards, giving everyone from machine operators to the C-suite access to the same accurate, up-to-date information. This “one version of the truth” eliminates the guesswork and finger-pointing that often happens when systems don’t align.

By replacing those disparate systems with a single, integrated platform, you’re not just simplifying your tech stack – you’re creating the foundation for smarter, faster decision-making across your entire manufacturing operation. For more details about how NetSuite solutions can transform your business processes, our team can help you explore the possibilities.

Discrete vs. Batch Manufacturing Support

Here’s where NetSuite Advanced Manufacturing really shines – it doesn’t force you into a one-size-fits-all approach. Whether you’re assembling complex machinery or mixing chemical formulations, the system adapts to your specific manufacturing style.

For discrete and assembly manufacturers, the platform offers parameterized configuration by location. This means you can customize production processes for different facilities or product lines without creating entirely separate systems. The system handles complex assembly workflows while giving you granular control over each step of your production process.

Batch and process manufacturers get specialized tools that understand their unique challenges. The Recipe and Formulation Management feature lets you maintain precise control over ingredients and processes, including managing alternate assets and co-products. When you’re dealing with perishable materials or strict quality requirements, the FIFO material issuance ensures your oldest materials get used first.

The system also generates automatic Batch Lot IDs and creates bar-code enabled Batch Travelers for full lot traceability. This isn’t just convenient – it’s essential for regulatory compliance and quality control. Whether you’re manufacturing semiconductors or food products, you’ll have complete visibility into every component that goes into your finished goods.

How it Extends Core NetSuite Manufacturing

NetSuite takes a smart, tiered approach to manufacturing that grows with your business. Most companies start simple and add complexity as they expand – and the platform supports this journey seamlessly.

You might begin with Work Orders & Assemblies for basic item builds, then graduate to WIP & Routings when you need work centers, labor costing, and capacity planning. But NetSuite Advanced Manufacturing represents the full evolution of these capabilities.

This isn’t just about adding WIP & Routings – it’s about gaining full MES and MOM capabilities that give you complete control over your production environment. The Manufacturing Workbench becomes your command center, providing real-time shop floor visibility and management tools that go far beyond basic work orders.

The real advantage? You get a seamless upgrade path from your current NetSuite manufacturing setup. No disruptive migrations, no data loss, no starting from scratch. Your existing processes continue working while you gradually open up more sophisticated capabilities.

To see how all these pieces work together, check out this helpful overview: Introducing Advanced Manufacturing. It demonstrates how the NetSuite Advanced Manufacturing user guide principles translate into real-world production control.

Core Features for Total Production Control

Picture having complete visibility and control over every aspect of your manufacturing operation. That’s exactly what NetSuite Advanced Manufacturing delivers through its comprehensive suite of production management tools.

The Manufacturing Workbench acts as your mission control center, bringing together all the moving pieces of your production environment in one intuitive dashboard. From here, you can seamlessly manage Work Orders, create detailed Routings, and track Labor Requirements with precision that would make a Swiss watchmaker proud.

But this isn’t just about pretty dashboards. The real power lies in shop floor control and variance management. You can compare actual costs against your standards in real-time, spotting inefficiencies before they become expensive problems. Every step, every material, and every minute of labor gets tracked, helping you define clear work instructions and establish realistic start and end times that your team can actually meet.

Advanced Planning and Scheduling

Remember the days of crossing your fingers and hoping your production schedule would somehow work out? Those days are officially over. Advanced planning and scheduling in NetSuite Advanced Manufacturing brings scientific precision to what used to be educated guesswork.

The system combines shop floor planning with both Rough Cut Capacity Planning and Finite Capacity Scheduling. Think of Rough Cut as your 30,000-foot view – it quickly tells you if you have enough overall capacity to meet demand. Finite Capacity Scheduling then zooms in to ensure work orders only get released when the specific machines and skilled workers are actually available.

The visual Gantt view with drag-and-drop functionality makes schedule adjustments feel almost effortless. Need to shift a production run because a machine went down? Just drag it to a new time slot. The system automatically considers resource utilization and machine and labor availability, preventing those dreaded over-commitments that create bottlenecks and stressed-out production managers.

Managing Work Centers and Resources

Every efficient manufacturing operation starts with well-organized Work Centers – think of them as the building blocks of your production floor. NetSuite Advanced Manufacturing helps you define these centers and track the resources that make them tick.

For each Work Center, you can monitor available hours, head count, and machine count, giving you crystal-clear visibility into your resource capacity. This isn’t just helpful for today’s planning – it’s essential for accurate reporting and future capacity decisions.

But let’s be realistic: things don’t always go according to plan. Machines break down, materials get damaged, and sometimes your star operator calls in sick. The system handles these realities through detailed downtime tracking using predefined Downtime Categories and Downtime Reasons. An operator can quickly log “Machine Breakdown” under a “Maintenance” category, often using simple barcode scanning.

Similarly, Material Loss tracking helps you identify where waste occurs and why. By capturing these events in real-time, you gain the insights needed to reduce inefficiencies and make data-driven improvements to your processes.

Batch Management and Compliance

For manufacturers working with batch and process operations, maintaining consistency and meeting regulatory requirements isn’t optional – it’s survival. NetSuite Advanced Manufacturing delivers robust recipe and formulation management that gives you precise control over every ingredient and process step.

The system automatically generates Batch Lot IDs, creating an unbroken chain of traceability from raw materials to finished products. This full lot traceability becomes invaluable when you need to investigate quality issues, manage recalls, or satisfy auditors who want to see exactly where every component came from.

Improved material issuance controls reduce errors and ensure the right materials end up in the right batches every time. While the specific compliance features vary by industry, having detailed, accurate records within a single system makes supporting regulatory requirements much more manageable.

When audit time comes around (and it always does), you’ll appreciate having all this information organized and accessible through your NetSuite Advanced Manufacturing user guide rather than scattered across multiple systems and paper trails. For more details about how NetSuite can transform your manufacturing operations, visit our comprehensive NetSuite solutions page.

Streamlining Shop Floor Operations in Practice

The true test of any manufacturing system happens where the rubber meets the road – on your shop floor. This is where NetSuite Advanced Manufacturing transforms from a sophisticated planning tool into a practical powerhouse that drives real results. When your production teams can access real-time data and make informed decisions instantly, you’ll see dramatic improvements in throughput while reducing your cost-to-produce.

The beauty of this system lies in its practical applications. Instead of relying on outdated paper trails and manual processes, your team gains access to mobile capabilities that turn every interaction into valuable data. This real-time data reporting creates a feedback loop that continuously improves your operations.

The Role of Work Order Travelers and Labor Codes

Think of Work Order Travelers as your production team’s GPS system. These comprehensive documents guide workers through every step of the manufacturing process, ensuring nothing gets missed along the way. When you generate these travelers from NetSuite Advanced Manufacturing, you’re creating more than just instructions – you’re building a roadmap to consistent quality.

Each traveler includes customizable information that’s specific to your operation. Process steps are clearly outlined, work instructions are detailed, and all required materials are listed. The real game-changer? These documents come with barcode-enabled functionality that eliminates guesswork and manual data entry.

But having the right instructions is only half the battle. You also need the right people doing the right jobs. That’s where Labor Codes become essential. These codes ensure skill alignment by matching workers with tasks that match their expertise and training level. When you align the right skills with the right operations, you’re not just reducing errors – you’re creating a more efficient and safer work environment.

Mobile Data Capture for Real-Time Insights

Gone are the days when shop floor data lived on clipboards and got entered into systems hours later. With NetSuite Advanced Manufacturing, your team can use wireless tablets to capture information as it happens, changing your shop floor into a connected, intelligent workspace.

Barcode scanning becomes second nature when workers can simply point and scan to record MES activities. Whether they’re reporting labor hours, tracking machine time, or logging unexpected downtime, everything flows directly into your system. This means you’re always working with current information instead of yesterday’s data.

The impact on decision-making is immediate. When a machine goes down, you know about it instantly rather than finding it during the next shift meeting. When production is running ahead of schedule, you can adjust resources in real-time to maximize the opportunity. For detailed information about NetSuite’s mobile capabilities, check out the Official NetSuite for Mobile documentation.

Performance Reporting and Analysis

Data without insights is just noise. NetSuite Advanced Manufacturing excels at turning your shop floor information into actionable intelligence through comprehensive operational performance reports. These reports don’t just tell you what happened – they help you understand why it happened and what you can do about it.

Comparing actual vs. standard production becomes straightforward when all your data flows into one system. You can see exactly where your processes are exceeding expectations and where they’re falling short. This data-driven process refinement approach takes the guesswork out of continuous improvement.

The real power comes from identifying inefficiencies before they become major problems. When you can spot patterns in downtime, material waste, or labor variances, you can address root causes rather than just symptoms. Cost variance analysis gives you the financial perspective you need to prioritize improvements and measure their impact on your bottom line.

This level of visibility transforms how you manage your operation. Instead of reacting to problems after they’ve impacted your schedule or budget, you can proactively optimize your processes based on real performance data.

Getting Started: Your NetSuite Advanced Manufacturing User Guide

Taking the first steps with NetSuite Advanced Manufacturing doesn’t have to feel overwhelming. Think of it as upgrading your manufacturing toolkit – you’re building on what you already have, not starting from scratch.

Before diving into the NetSuite Advanced Manufacturing user guide, let’s make sure you have the right foundation. You’ll need an active NetSuite ERP subscription as your starting point. The Advanced Manufacturing SuiteApp isn’t a standalone solution – it’s designed to extend your existing NetSuite manufacturing capabilities, which means you’ll typically need the Work Orders and Assemblies module and the WIP and Routings module already in place.

These aren’t just technical requirements; they’re the stepping stones that make Advanced Manufacturing so powerful. Each module builds naturally on the last, creating a seamless upgrade path that grows with your business needs.

The setup process does require some collaboration with NetSuite Professional Services or an experienced implementation partner. This isn’t a limitation – it’s actually a strength. These experts ensure your system is configured to match your unique business processes, not some generic template. When you’re ready to explore your options, our NetSuite Pricing page can help you understand the investment involved.

Accessing the Official NetSuite Advanced Manufacturing User Guide

Finding the official documentation is straightforward once you know where to look. The NetSuite Advanced Manufacturing user guide lives in the NetSuite Help Center, and it’s your most comprehensive resource for detailed instructions and explanations.

The guide is thoughtfully organized into key sections that take you from setup through daily operations. You’ll find Prerequisites that ensure your NetSuite environment is ready, Administration Settings for initial configuration, and detailed sections on Assemblies and Routings to set up your production processes. The guide also covers Record Creation for manufacturing-specific records, Production Planning to strategize your output, and Production Scheduling to organize your timeline.

What makes this guide particularly valuable are the practical sections on Shop Floor Management and Data Collection. These provide real-world advice for managing day-to-day operations and capturing crucial performance data. The Report Management section ties it all together, showing you how to generate and analyze the reports that drive better decisions.

You can access this invaluable resource directly here: Advanced Manufacturing User Guide.

Key Differences: A Quick NetSuite Advanced Manufacturing User Guide Comparison

Understanding where NetSuite Advanced Manufacturing fits in NetSuite’s manufacturing ecosystem helps you make informed decisions about your upgrade path. NetSuite designed a progressive approach that lets you adopt functionality as your business grows, rather than forcing you into an all-or-nothing decision.

| Feature | Work Orders & Assemblies | WIP & Routings | Advanced Manufacturing |

|---|---|---|---|

| WIP Tracking | No | Yes | Yes |

| Work Centers | No | Yes | Yes |

| Routings | No | Yes | Yes |

| Labor Costing | No | Yes | Yes |

| Capacity Scheduling | No | Infinite Capacity | Finite Capacity |

| Gantt View | No | Yes (Drag-and-Drop) | Yes (Drag-and-Drop) |

| MES Capabilities | No | Limited | Full |

| Batch Management | No | No | Yes |

| Lot Traceability | Basic | Basic | Advanced |

| Mobile Data Capture | No | Limited | Yes (Real-time) |

| Work Order Control | Basic | Standard | Advanced |

The beauty of this tiered approach is that each option builds naturally on the last. Work Orders & Assemblies handles basic manufacturing needs, WIP & Routings adds work centers and scheduling capabilities, and Advanced Manufacturing delivers the full suite of MES capabilities, batch management, and real-time mobile data capture.

What’s particularly impressive is the seamless upgrade path between these options. You’re not locked into a decision – you can start where it makes sense for your business today and grow into more advanced capabilities as your needs evolve.

Frequently Asked Questions about NetSuite Advanced Manufacturing

When businesses start exploring NetSuite Advanced Manufacturing, we hear the same thoughtful questions time and again. These are the ones that matter most to decision-makers who want to understand exactly what they’re getting into.

What is the pricing for NetSuite Advanced Manufacturing?

NetSuite Advanced Manufacturing follows a module-based pricing structure, which means it’s an add-on to your existing NetSuite subscription rather than a standalone product. The beauty of this approach is that you’re building on what you already have, not starting from scratch.

Pricing varies based on several factors that make sense when you think about it. Your total user count plays a role, as does your existing NetSuite configuration and contract terms. Rather than throwing out numbers that might not apply to your specific situation, we always recommend getting a custom quote that reflects your actual business needs.

This is where working with an experienced NetSuite partner becomes invaluable. We can help you understand not just the cost, but how the investment fits into your broader digital change goals and what kind of return you can expect.

How does Advanced Manufacturing integrate with NetSuite WMS?

The integration between NetSuite Advanced Manufacturing and NetSuite’s Warehouse Management System is one of those “it just works” situations that makes your life easier. Everything flows together seamlessly, which is exactly what you want when you’re trying to run efficient operations.

When materials get consumed on the shop floor or finished goods roll off the production line, your warehouse inventory updates automatically in real-time. No more manual reconciliation at the end of the day or week. No more wondering if your inventory numbers are accurate.

The system also streamlines material picking for work orders and ensures that component consumption is tracked accurately. This means improved inventory accuracy from the shop floor all the way to the warehouse. It’s like having one brain managing your entire operation instead of multiple systems trying to talk to each other.

What are the main prerequisites for implementation?

Getting started with NetSuite Advanced Manufacturing requires a few building blocks to be in place first. You’ll need an active NetSuite ERP subscription, which makes sense since this is an extension of your existing system.

The NetSuite Advanced Manufacturing user guide typically requires that you have the Work Orders and Assemblies module already enabled in your NetSuite instance. You’ll also need the WIP and Routings module, as these provide the foundation that Advanced Manufacturing builds upon.

But here’s the thing – the technical prerequisites are just part of the story. The most successful implementations happen when you work closely with an experienced implementation partner who understands manufacturing. We take the time to learn your unique processes and configure the system to work the way you do business, not the other way around.

This collaborative approach means you’re not just installing software – you’re optimizing your entire manufacturing operation from day one. That’s the difference between a technical installation and a true digital change.

Optimize Your Production with an Expert Partner

The journey through the NetSuite Advanced Manufacturing user guide reveals incredible possibilities for changing your production operations. We’ve explored how this powerful platform can increase efficiency, reduce costs, and give you the kind of operational control that makes a real difference in your bottom line.

But here’s the thing – having access to great software is just the beginning. The real change happens when you have the right partner to guide you through implementation and optimization.

At Nuage, we’re not your typical software vendor. We don’t push one-size-fits-all solutions or rush you into decisions. Instead, we take the time to understand your unique manufacturing challenges and help you determine the right approach. Think of us as your NetSuite Optimization Engine – we’re here to ensure every feature works hard for your business.

Our team brings over 20 years of digital change experience to the table. We’ve seen manufacturers struggle with disconnected systems, and we’ve celebrated with them as they gained control through integrated solutions like NetSuite Advanced Manufacturing. We know the common pitfalls, the hidden opportunities, and the best practices that make implementations successful.

What sets us apart is our commitment to being true partners in your success. We’re not just here for the implementation – we stick around to provide ongoing support as your business grows and evolves. Whether you’re dealing with complex batch processes, managing multiple work centers, or trying to achieve better shop floor visibility, we’ve got the expertise to help you succeed.

Our locations in Manhattan Beach, CA, and Ponte Vedra and Jacksonville, FL, position us to serve manufacturers across the country. But more importantly, our experience with NetSuite solutions means we understand both the technical capabilities and the business impact of Advanced Manufacturing.

Ready to see how NetSuite Advanced Manufacturing can transform your operations? We’d love to help you assess your current manufacturing landscape and identify the opportunities that matter most to your business. Get a NetSuite Assessment with our team today, and let’s start building a more efficient, more profitable future for your manufacturing operation.

Last Updated: January 3, 2026

Looking for help optimizing your NetSuite? Contact our team for a free consultation.

Optimize Your NetSuite Manufacturing Setup

At Nuage, we specialize in NetSuite Optimization for manufacturing companies. Our team can help you maximize your Advanced Manufacturing module and improve production efficiency.

Watch our interview with Majid Abai, Chairman & CEO of Bay Cities Metal Products, where he shares how they optimized their NetSuite manufacturing processes:

Need ongoing support? Our Managed Services team provides continuous optimization and 24/7 Support for manufacturing operations.

Not sure if your NetSuite is optimized? Take our free NetSuite Scorecard to get a personalized assessment.

Want to see how we’ve helped other companies? Check out our customer success stories.

Last Updated: January 4, 2026