Why Modern Manufacturers Are Turning to Advanced ERP

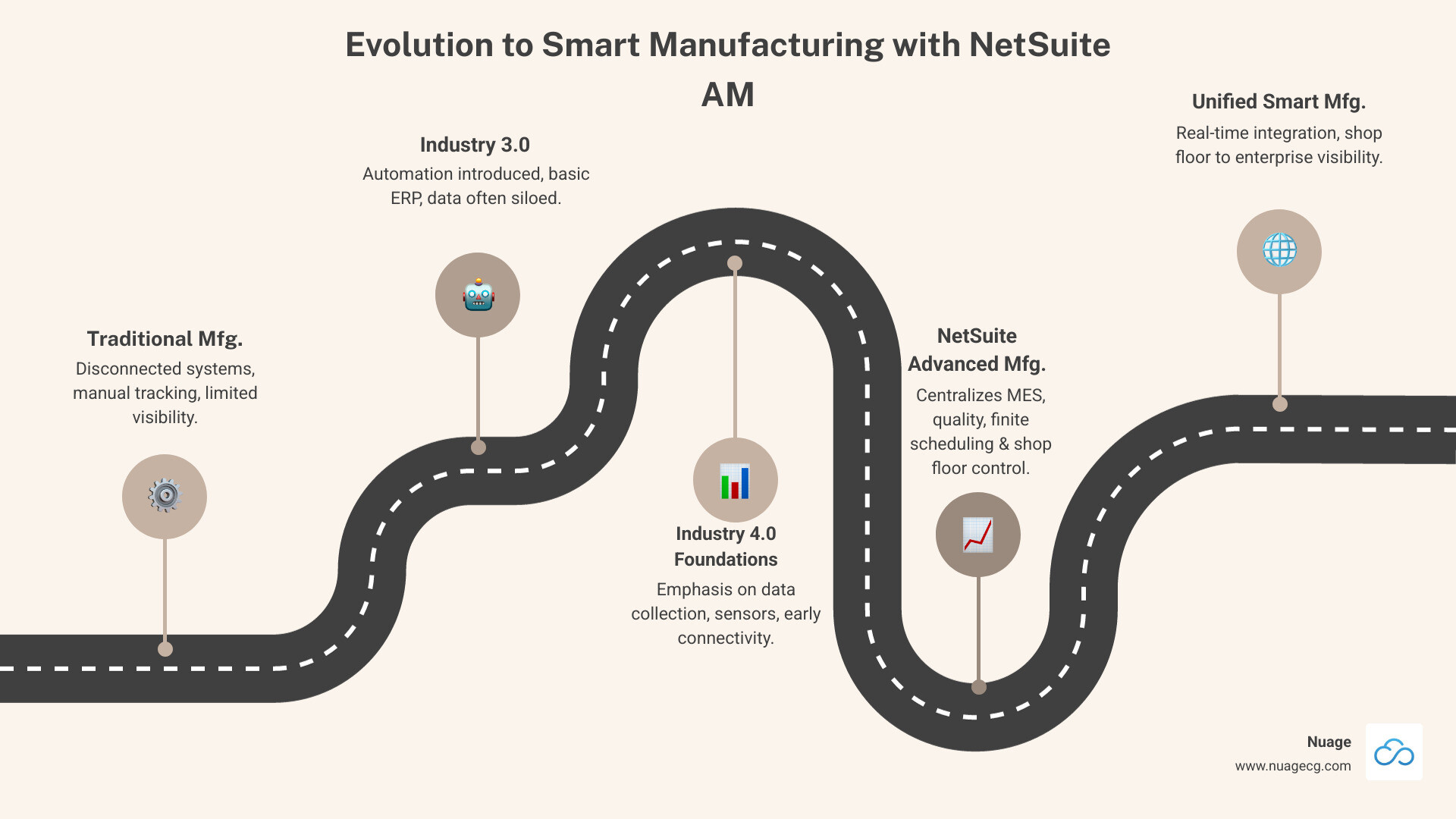

Manufacturing is tougher than ever, with persistent supply chain disruptions, labor shortages, and the challenge of juggling disconnected systems. The shift toward Industry 4.0 requires unifying all manufacturing data in one place, connecting the shop floor to the top floor for real-time visibility and control.

NetSuite advanced manufacturing is a comprehensive SuiteApp that extends NetSuite’s core ERP to provide this control. It delivers full Manufacturing Execution System (MES) capabilities, batch control, and real-time integration between shop floor and enterprise systems.

Key capabilities include:

- Finite capacity scheduling to optimize resources

- Mobile shop floor control for paperless operations

- Manufacturing Work Bench for centralized management

- Quality management with inspection workflows and traceability

- Support for both discrete and batch manufacturing

As one specialty bakery owner put it: “With NetSuite Advanced Manufacturing we have a flagship business and manufacturing system. The integrated solution is seamless and is the best that I have worked with including the largest Tier 1 solutions.”

I’m Louis Balla, CRO and partner at Nuage. With over 15 years in digital change and supply chain operations, I’ve seen how moving to a truly integrated manufacturing system like NetSuite advanced manufacturing open ups significant operational improvements.

Essential netsuite advanced manufacturing terms:

What is NetSuite Advanced Manufacturing?

NetSuite Advanced Manufacturing is a complete manufacturing toolkit that sits on top of your core NetSuite ERP. As a SuiteApp, it integrates seamlessly to transform your ERP into a full-fledged manufacturing command center. Instead of juggling separate systems for production planning, shop floor tracking, and quality control, everything lives in one place. Your production team sees the same real-time data as your finance team, creating a single source of truth.

This plant-to-enterprise integration drives profitability. It reduces operating costs by optimizing inventory and improves supply chain management by unifying demand signals and production constraints. You can make better decisions faster, catching problems before they become expensive and knowing what’s happening in your operation right now, not yesterday.

Want to dive deeper into how NetSuite can transform your operations? Learn more about the NetSuite platform.

How it Differs from Standard Manufacturing Modules

NetSuite offers three tiers of manufacturing functionality, providing a clear growth path without forcing you to buy everything upfront.

Work Orders & Assemblies is the starting point, ideal for light assembly, kitting, or basic manufacturing. It allows you to create Bills of Material and issue work orders, but it lacks work-in-process (WIP) tracking, labor costing, and detailed shop floor control.

WIP & Routings adds more advanced capabilities. It introduces work centers, detailed production routings, and tracking for labor and machine costs. It also provides a Gantt chart for scheduling based on infinite capacity, which assumes unlimited resources. This is useful for planning but doesn’t reflect real-world constraints.

Advanced Manufacturing is the complete suite. It includes all features from the lower tiers and adds critical capabilities like finite capacity scheduling, which accounts for actual machine and labor availability. It delivers a full Manufacturing Execution System (MES) for real-time shop floor data collection via tablets, integrated quality management, and batch control for process manufacturers. The Manufacturing Work Bench provides a centralized dashboard for total production visibility.

| Feature / Module | Work Orders & Assemblies | WIP & Routings | Advanced Manufacturing |

|---|---|---|---|

| Primary Use | Basic assembly, light manufacturing | More complex production, tracking WIP | Full manufacturing control, complex processes |

| Work-in-Process (WIP) Tracking | No | Yes (basic) | Yes (detailed) |

| Routings & Work Centers | No | Yes | Yes (improved) |

| Labor Costing | No | Yes | Yes (detailed) |

| Capacity Scheduling | None (basic infinite) | Infinite | Finite (with MES) |

| Shop Floor Control | Basic work order completion | Limited data collection | Comprehensive MES, mobile data collection |

| Quality Management | No | No | Yes (optional, integrated) |

| Batch/Process Mfg. Support | No | No | Yes (recipe management, lot control) |

| Detailed Work Instructions | No | Basic | Yes |

| Gantt Chart Scheduling | No | Yes | Yes (improved) |

At Nuage, we help manufacturers determine the right tier for their current and future needs. NetSuite’s scalable approach allows you to upgrade as you grow, bringing your existing configurations with you without complex data migration or reimplementation projects.

Core Capabilities and Key Features

NetSuite Advanced Manufacturing is a complete system designed to transform production operations by delivering improved operational effectiveness, reduced production costs, and increased revenue. It provides granular control and real-time visibility into every aspect of the manufacturing process. A key feature is variance management, allowing you to compare actual costs and performance against standards in real-time to spot issues early and protect margins.

The Manufacturing Work Bench and Shop Floor Control

The Manufacturing Work Bench is the mission control for your production floor. This centralized hub extends NetSuite’s routing into an interactive interface for managing the entire production process.

- Centralized work order management: Create, release, and track orders from a single dashboard.

- Real-time visibility: Monitor production progress, material consumption, and labor allocation as it happens.

- Standardized work instructions: Ensure consistency and reduce quality issues by providing operators with accessible, detailed instructions.

- Shop floor travelers: Use bar-code enabled documents that accompany work orders to provide information and collect data.

- Precise routing definitions: Specify the exact work centers, operations, and resources needed for each product.

- Downtime tracking: Capture the reasons for production slowdowns (e.g., maintenance, material shortages) to identify and eliminate bottlenecks.

- Material loss tracking: Record waste with specific reasons (e.g., spoilage, scrap) to drive cost reduction efforts.

- Labor codes: Ensure only qualified personnel are assigned to specific tasks, improving safety and minimizing errors.

Advanced Planning and Scheduling

NetSuite Advanced Manufacturing excels at complex scheduling by using finite capacity scheduling. Unlike systems that assume unlimited resources, it considers the actual availability of your machines and labor to create realistic production plans.

- Rough-cut capacity planning (RCCP): Get a high-level assessment of your master production schedule’s feasibility.

- Resource management: Track machine and labor utilization in detail to balance capacity with demand.

- Gantt chart view: A visual, drag-and-drop interface makes schedule adjustments straightforward.

- Dispatch lists: Provide prioritized work orders for each work center to guide shop floor execution.

This level of planning reduces lead times and improves on-time delivery, which are critical metrics for customer satisfaction. Want to see it in action? Watch a video on Advanced Manufacturing.

Mobile Data Collection and MES

The mobile application digitizes shop floor operations, moving you beyond slow, error-prone paper systems. Designed for manufacturing environments, it enables paperless operations by eliminating manual data entry.

- Real-time data entry: Operators record production completions, material consumption, scrap, and downtime directly on the factory floor.

- Barcode scanning: Streamline material issuance, component tracking, and work order completion for greater speed and accuracy.

This mobile app is a key component of your Manufacturing Execution System (MES), providing real-time reporting of production events, labor, and machine hours. It also supports lite WMS transactions like PO receipts, material issuance, and pick, pack, and ship operations. The result is comprehensive performance reports that help you identify bottlenecks using data you can trust. For more on how mobile capabilities integrate with warehouse management, explore mobile manufacturing execution solutions.

Who Benefits Most from NetSuite Advanced Manufacturing?

NetSuite Advanced Manufacturing is built to handle real-world complexity, adapting to specific production needs across various industries, from automotive plants to food processors.

For Discrete and Assembly Manufacturers

Discrete manufacturers produce items that can be counted and assembled, like cars, electronics, or medical equipment. NetSuite Advanced Manufacturing handles the full spectrum of discrete production strategies:

- Make-to-stock (MTS): Optimizes scheduling and material planning for standard products built for inventory.

- Assemble-to-order (ATO): Manages custom configurations for products assembled after a customer order is placed.

- Engineer-to-order (ETO): Provides the flexibility to handle complex Bills of Material (BOMs) and custom routings for unique, designed-from-scratch products.

The advanced BOM capabilities support multi-level and phantom assemblies, while routing management allows for primary and alternate production paths with finite planning. A key feature is component yield tracking, which builds expected scrap rates into material planning to prevent mid-production shortages.

Industry Use Cases:

- Automotive: Manage thousands of vehicle configurations while maintaining quality traceability.

- High-Tech: Automate configure-to-order workflows and manage engineering change orders.

- Industrial Equipment: Handle ETO customization and integrate field service data.

- Medical Devices: Provide the batch and serial tracking needed for regulatory compliance and product recalls.

For Batch and Process Manufacturers

Process manufacturing involves mixing, blending, or formulating products that cannot be disassembled, such as food, chemicals, or pharmaceuticals. NetSuite Advanced Manufacturing addresses this through specialized recipe and formula management.

The system accurately tracks co-products and by-products — multiple outputs from a single production run — ensuring inventory and costing remain aligned with reality. Lot traceability is critical, providing automatic batch lot ID assignment and full track-and-trace capabilities. This is essential for quality control, regulatory compliance, and managing potential recalls.

Other key features include batch control for precise management of production quantities and FIFO material issuance to ensure older, shelf-life-sensitive ingredients are used first.

Industry Use Cases:

- Food and Beverage: Manage batch ticket workflows, manufacturing date control, and warehouse quality inspections.

- Chemicals: Steer complex regulatory requirements with integrated financials and complete traceability.

- Pharmaceuticals: Provide the stringent quality control and documentation needed to satisfy regulators.

Implementation, Integration, and Best Practices

Implementing NetSuite Advanced Manufacturing is a strategic investment that requires careful planning and execution to maximize its value. Success depends on proper setup, smart integration, and understanding system best practices.

Essential Setup and Prerequisites for netsuite advanced manufacturing

A solid foundation is critical. The initial setup is complex, which is why engaging NetSuite Professional Services, like our team at Nuage, is highly recommended.

- Install the SuiteApp: The Advanced Manufacturing SuiteApp must be installed in your NetSuite account.

- Configure Core Features: The underlying infrastructure must be set up correctly from day one.

- Define Work Centers: These represent your physical machines or resource groups. It’s critical to maintain a 1-to-1 mapping between Advanced Manufacturing Work Centers and NetSuite Work Centers, with matching names.

- Set Administration Settings: These rules govern how the module operates within your NetSuite instance.

- Configure Items and Routings: Define your assembly items and the detailed sequence of operations required to produce them.

- Set Employee Permissions: Grant the right access levels to ensure security and usability.

Post-implementation setup is primarily for administrators. For technical details, see the NetSuite Advanced Manufacturing User Guide.

Integration with the NetSuite Ecosystem

A key strength of NetSuite Advanced Manufacturing is its native integration within the NetSuite ecosystem, ensuring data flows seamlessly across your entire business.

- Financials: Production costs, WIP valuation, and inventory adjustments are reflected in the general ledger in real-time.

- Inventory and WMS: Gain real-time visibility into raw materials, WIP, and finished goods. Integration with NetSuite WMS provides even tighter control.

- CRM: The sales team can see actual production capacity and lead times, allowing them to set realistic customer expectations.

This plant-to-enterprise (P2E) integration creates a unified data model, connecting the shop floor to enterprise-level reporting. While native capabilities are robust, NetSuite also integrates with specialized third-party systems like Quality Management Systems (QMS) or via EDI with supply chain partners.

Best Practices and Known Limitations for netsuite advanced manufacturing

Knowing the system’s quirks helps you work with it effectively.

- BOM Revisions: Regularly remove inactive items from BOM Revision records before creating new work orders.

- Component Yield: If using this feature, double-check that the ‘Use Component Yield’ box is checked on the assembly BOM.

- Mobile Tablet Limit: The mobile interface has a hard limit of 45 operations per work order to avoid script timeouts. Long routings may need to be segmented.

- Work Order State: For full scheduling, work orders must be in the ‘Released’ state, not ‘Planned’.

- Lot/Serial Items: The SuiteApp does not automatically issue Lot and Serial items; this requires a manual process or specific configuration.

- Traveler Errors: If you encounter ‘SSSUSAGELIMIT_EXCEEDED’ errors when generating travelers, increase the script yield limit on the deployment record.

- Mobile Data Capture: Use mobile devices for real-time shop floor data capture to generate valuable operational performance reports.

For more details, consult the official Best Practices Guide. Our team at Nuage exists to help you steer these nuances.

Frequently Asked Questions about NetSuite Advanced Manufacturing

How does NetSuite Advanced Manufacturing improve operational efficiency?

NetSuite Advanced Manufacturing improves efficiency by automating manual processes and providing real-time visibility from the shop floor to the top floor. Key features include:

- Finite Capacity Scheduling: Creates realistic production plans by considering actual machine and labor availability, preventing over-allocation and reducing downtime.

- Real-Time Data: Instant visibility into factory floor operations allows managers to spot and address bottlenecks as they happen, not after the fact.

- Resource Utilization: Better visibility into how resources are used helps balance workloads, reduce idle time, and shorten production lead times.

Can it handle complex production environments like engineer-to-order?

Yes. NetSuite Advanced Manufacturing is designed for complexity and provides the flexibility needed for various production strategies, including:

- Engineer-to-order (ETO): Supports multi-level Bills of Material (BOMs), custom routings, and flexible resource requirements for unique products.

- Make-to-order (MTO) and Configure-to-order (CTO): Accommodates diverse product configurations while maintaining control and visibility to ensure on-time delivery.

The system is scalable, adapting to evolving processes and increasing product complexity without requiring a full reimplementation.

How does it improve product quality and compliance?

NetSuite Advanced Manufacturing integrates quality control directly into the production workflow to improve product quality and ensure regulatory compliance.

- Integrated Quality Management: Define inspection plans for any production stage, collect results digitally, and manage non-conformances with documented follow-up.

- Lot and Serial Traceability: Provides full track-and-trace capabilities throughout the production lifecycle, which is non-negotiable for regulated industries like food, pharmaceuticals, and medical devices. This allows for quick and accurate tracing of components and finished goods, which is critical for audits, brand protection, and managing potential recalls.

Conclusion: Driving Manufacturing Excellence with a Unified Solution

NetSuite Advanced Manufacturing is more than a set of features; it’s a strategic platform for navigating today’s complex market. This unified cloud solution transforms operations from reactive firefighting into proactive excellence. The benefits are tangible, with manufacturers often seeing productivity improvements of 30-50% and significant reductions in material waste.

The most critical advantage is real-time visibility across the entire production process. Instead of relying on outdated reports, you make decisions with accurate, up-to-the-minute data flowing from the shop floor to your financial and planning systems. This allows you to adapt quickly to shifting demands, identify bottlenecks before they become crises, and manage costs with precision.

The future of manufacturing belongs to companies that are agile, efficient, and operate from a single source of truth. NetSuite Advanced Manufacturing provides the foundation for this, enabling scalable growth.

At Nuage, we are your NetSuite Optimization Engine. With over 20 years of experience in digital change, we don’t offer one-size-fits-all solutions. We partner with you to determine the right configuration, guide you through implementation, and provide ongoing support. We’re here to help you open up the full potential of your manufacturing operations.

Ready to take the next step? Optimize your manufacturing operations with our NetSuite solutions and see what’s possible when your entire production ecosystem works as one.