NetSuite Advanced Manufacturing: The Complete 2025 Guide

Opening up Manufacturing Excellence with a Unified System

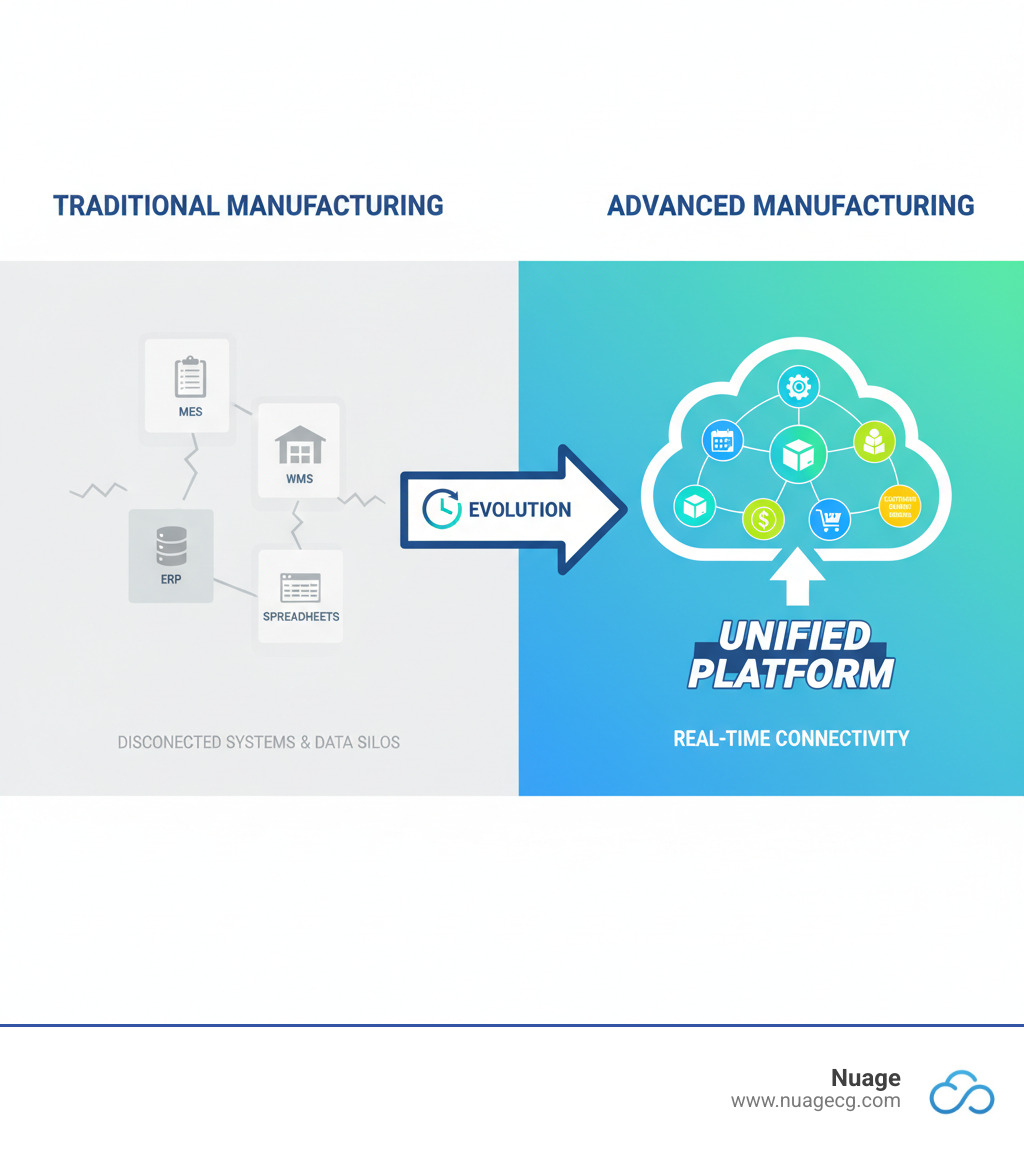

If your company struggles with manual data entry, delayed reporting, and disconnected systems, you’re losing visibility and efficiency. NetSuite Advanced Manufacturing solves this by replacing disparate systems with a single, cloud-based platform that integrates production planning, shop floor control, and financials.

Key capabilities include:

- Single integrated system to eliminate data silos.

- Real-time visibility connecting the shop floor to enterprise reporting.

- Three scalable deployment tiers from basic assembly to full MES.

- Mobile-ready operations with barcode scanning for production tracking.

- Finite capacity scheduling to optimize resource use.

Using disconnected ERP, MES, and WMS systems can increase error rates by up to 40%. The solution is a unified source of truth connecting every step from order to shipment. While the technology exists to improve productivity by 30-50%, many companies face internal problems. The challenge is bridging the gap between your current state and what’s possible.

I’m Louis Balla, and with 15 years in digital change and supply chain management, I’ve helped manufacturers implement NetSuite Advanced Manufacturing to eliminate bottlenecks and achieve measurable ROI. My experience with NetSuite and third-party applications ensures the solution is custom to your specific operational needs.

What is NetSuite Advanced Manufacturing?

Think of NetSuite Advanced Manufacturing as the central nervous system for your production operations. It’s a cloud-based solution that replaces the frustrating patchwork of spreadsheets and disconnected software many manufacturers use daily.

Instead of juggling multiple systems, you get a single source of truth for everything from production schedules to financial reports, all updated in real-time. When a work order is completed, inventory adjusts automatically. When materials are issued, costing updates instantly. This eliminates end-of-month surprises and manual data reconciliation.

Because it’s built on the NetSuite ERP platform, your manufacturing processes connect seamlessly to financials, customer orders, and your supply chain. You can trace an order from creation through production to shipment without switching systems. For a quick visual walkthrough, Oracle offers a helpful video: Introducing Advanced Manufacturing.

At Nuage, we focus on finding ERP Solutions for Manufacturing that fit how you work. The goal is to reduce operating costs and gain control over production, not just implement software. Our NetSuite ERP for Manufacturing guide explores these options in more detail.

Differentiating NetSuite’s Manufacturing Tiers

NetSuite offers three manufacturing tiers, allowing you to start with what you need and scale as your operations grow more complex.

- Work Orders & Assemblies: The entry point for light assembly and kitting. It manages component tracking for standard configurations but lacks WIP tracking and detailed routing.

- WIP & Routings: Adds a middle layer of sophistication. This tier lets you define how products move through work centers, with labor costing, basic WIP tracking, and an infinite capacity scheduler. It’s ideal for coordinating multiple production stages without complex capacity constraints.

- NetSuite Advanced Manufacturing: The complete solution. It includes all features from the other tiers plus finite capacity scheduling, full MES capabilities, batch manufacturing support, and mobile data collection. It’s designed for manufacturers needing deep visibility and real-time control.

| Feature/Module | Work Orders & Assemblies | WIP & Routings | NetSuite Advanced Manufacturing |

|---|---|---|---|

| Primary Use Case | Light assembly, kitting | Basic production with work centers and labor | Complex, high-volume, or process-driven manufacturing |

| WIP Tracking | No | Yes (basic) | Yes (advanced, with granular control) |

| Routings | No | Yes (infinite capacity) | Yes (finite capacity, detailed work instructions) |

| Scheduling | Basic | Infinite capacity scheduling (Gantt chart) | Finite capacity scheduling, dynamic schedule codes |

| Shop Floor Control | No | Limited (manual reporting) | Full MES capabilities, mobile data collection |

| Costing | Standard | Basic labor/overhead costing | Advanced variance management, activity-based costing |

| Batch/Process Mfg. | No | No | Yes (recipe/formulation, co-products, lot traceability) |

| Mobile Capabilities | No | No | Yes (barcode scanning, real-time MES reporting) |

| Work Bench | No | No | Yes (Advanced Manufacturing Work Bench) |

| Complexity Handled | Simple | Moderate | High |

| Upgrade Path | To WIP & Routings | To Advanced Manufacturing | N/A (top tier) |

The tiered approach ensures you’re never locked in. You can upgrade as your business grows without needing to reimplement. Our NetSuite Manufacturing Guide 2025 breaks down these tiers with specific use-case scenarios.

Core Benefits for Modern Manufacturers

The real question isn’t what the software does, but what it means for your business. We’ve seen manufacturers cut production costs by 30% and reduce time-to-market by weeks. Here’s how:

- Improved operational effectiveness: Eliminates friction by capturing data once at the source, removing manual entry, errors, and delays.

- Reduced production costs: Real-time visibility into material, labor, and overhead costs helps you spot and fix problems instantly, minimizing waste.

- Faster time-to-value: A closed-loop system connecting design, production, and feedback can reduce time-to-market by over 20%.

- Improved quality control: Move from reactive to systematic quality control by monitoring metrics in real-time, automating inspections, and tracking corrective actions within the system.

- Variance management: Automatically compare actual costs and times against standards to immediately see and investigate budget or schedule deviations.

- Plant-to-Enterprise integration: Connects the shop floor directly to the executive dashboard, ensuring everyone works from a single version of the truth. This is the foundation of a successful Digital Transformation for Manufacturers.

Core Functionalities of NetSuite Advanced Manufacturing

The power of NetSuite Advanced Manufacturing lies in its ability to unify production control, resource optimization, and complete visibility from the shop floor to the executive suite. It provides a clear, real-time window into your entire manufacturing operation.

Custom Solutions for Discrete and Batch Manufacturing

NetSuite Advanced Manufacturing adapts to your production style, whether you build individual products or produce goods in large batches.

For discrete and assembly manufacturers (e.g., electronics, machinery), the module offers parameterized configurations for product variations, configurable work order completion logic, and improved operations routings with detailed work instructions.

For batch or process manufacturing (e.g., food, chemicals, pharmaceuticals), it provides specialized features for ERP for Batch Manufacturing and ERP for Process Manufacturing. Key capabilities include recipe and formulation management, co-product and by-product handling, FIFO material issuance to ensure inventory rotation, and complete lot traceability for quality control and regulatory compliance.

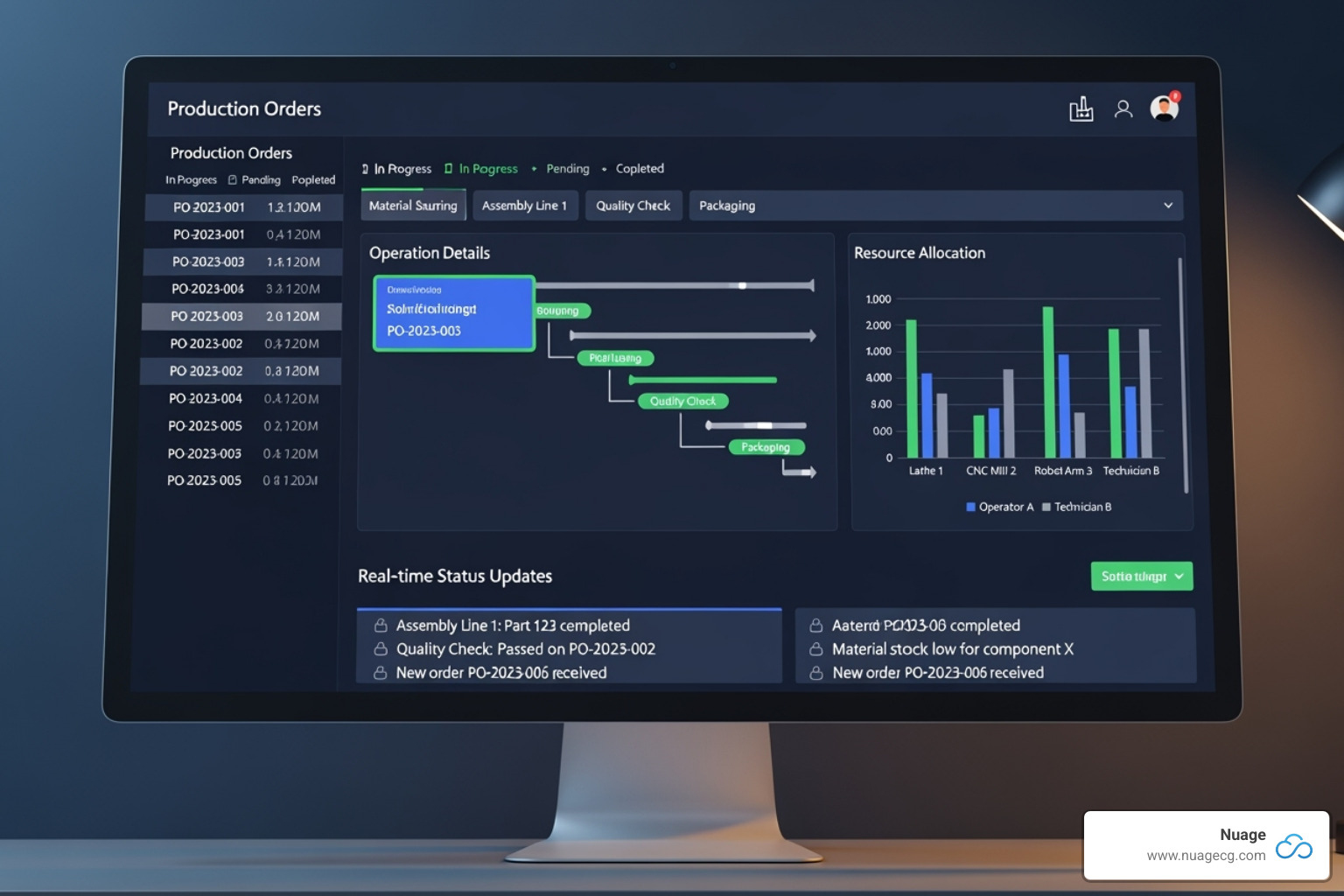

The Advanced Manufacturing Work Bench and MES

The Advanced Manufacturing Work Bench is your command center where planning meets execution. It transforms standard manufacturing routing into an interactive, powerful environment. Here, you can define work instructions, associate material usage with tasks, plan resources, and set planned start and end times for each operation.

The integrated Manufacturing Execution System (MES) brings active, real-time control to your shop floor. It provides live production progress, downtime tracking to identify inefficiencies, and accurate labor reporting against specific operations. The Work Bench and MES create a continuous feedback loop: shop floor data refines planning, and better planning improves shop floor performance.

Planning, Scheduling, and Execution Engine

NetSuite Advanced Manufacturing provides intelligent scheduling tools that respect your operational constraints.

Rough-Cut Capacity Planning (RCCP) acts as a reality check, allowing you to test the feasibility of your master production schedule against available resources and spot bottlenecks early.

Finite Capacity Scheduling is a key differentiator. Unlike systems that assume infinite resources, it works with your actual machine, labor, and tooling constraints. This creates realistic, achievable schedules that optimize throughput and minimize idle time. You can use dynamic schedule codes to prioritize orders and adjust on the fly. The engine ensures your plan stays accurate by incorporating real-time updates from the shop floor.

This comprehensive engine helps you make the right product at the right time with the right resources, directly impacting your bottom line. For more details, see NetSuite’s resource on What Is Advanced Manufacturing?

Implementation and Best Practices

Implementing NetSuite Advanced Manufacturing is a strategic journey, not just a software installation. Successful rollouts treat it as an ongoing evolution. Based on our experience with ERP Implementation Manufacturing Industry, a smooth transition depends on getting the fundamentals right upfront.

Key Setup and Administrative Considerations

Proper setup is critical for a smooth-running system. Here are the foundational steps:

- SuiteApp Installation: Ensure the Advanced Manufacturing SuiteApp is installed in your NetSuite account.

- Admin Console Configuration: Use the Advanced Manufacturing Admin Console to set up core behaviors and workflows.

- Work Center Mapping: Your Advanced Manufacturing Work Centers and standard NetSuite Work Centers must have identical names and matching statuses. This 1-to-1 mapping is essential for accurate scheduling.

- User Roles and Permissions: Configure roles to give everyone from operators to managers the appropriate level of access to do their jobs securely.

Navigating these setup tasks can be complex. Our team at Nuage specializes in NetSuite ERP Implementation and can save you weeks of trial and error.

Leveraging Mobile for Shop Floor Data Collection

Mobile capabilities bring real-time data collection to the shop floor, eliminating clipboards and manual entry. Operators can use barcode scanning on wireless tablets to instantly record material issuance, work order completions, and labor. Data flows into NetSuite the moment it’s captured, ensuring your inventory and schedules are always current.

The NetSuite Manufacturing Mobile SuiteApp provides fully integrated barcode scanning for true MES reporting. Solutions like NetSuite Advanced Manufacturing Solution – RF-SMART can improve this with even more sophisticated shop floor management tools.

Best Practices and Common Pitfalls

Avoid common headaches by following these best practices we’ve learned from years of implementations:

- Bill of Materials (BOM) Management: When marking an item inactive, you must manually remove it from any BOM Revision records before creating new work orders. To account for waste, check the ‘Use Component Yield’ box on both the assembly BOM record and the Bill of Materials page.

- BOM Revisions: The ‘Issued Step’ and ‘Auto-Issue’ columns on a BOM only populate when a work order is first created, not when edited. Finalize BOMs before generating work orders.

- Work Order Status: For end-to-end scheduling to work, work orders must be in ‘Released’ status. ‘Planned’ work orders will not schedule correctly.

- Scheduling Limitations: The system does not support scheduling for non-WIP or WIP-enabled non-routing work orders. Keep this in mind when designing production flows.

- Traveler Customization: Adding fields to traveler templates often requires XML expertise. This is a task best handled by NetSuite Professional Services or an experienced partner like Nuage.

- Bulk Traveler Generation: If you encounter a ‘SSSUSAGELIMIT_EXCEEDED’ error when printing travelers for large work orders, increase the script yield limit to 500 on the script deployment record to prevent timeouts.

Our NetSuite Optimization Services help you steer these nuances to ensure your system runs at peak performance from day one.

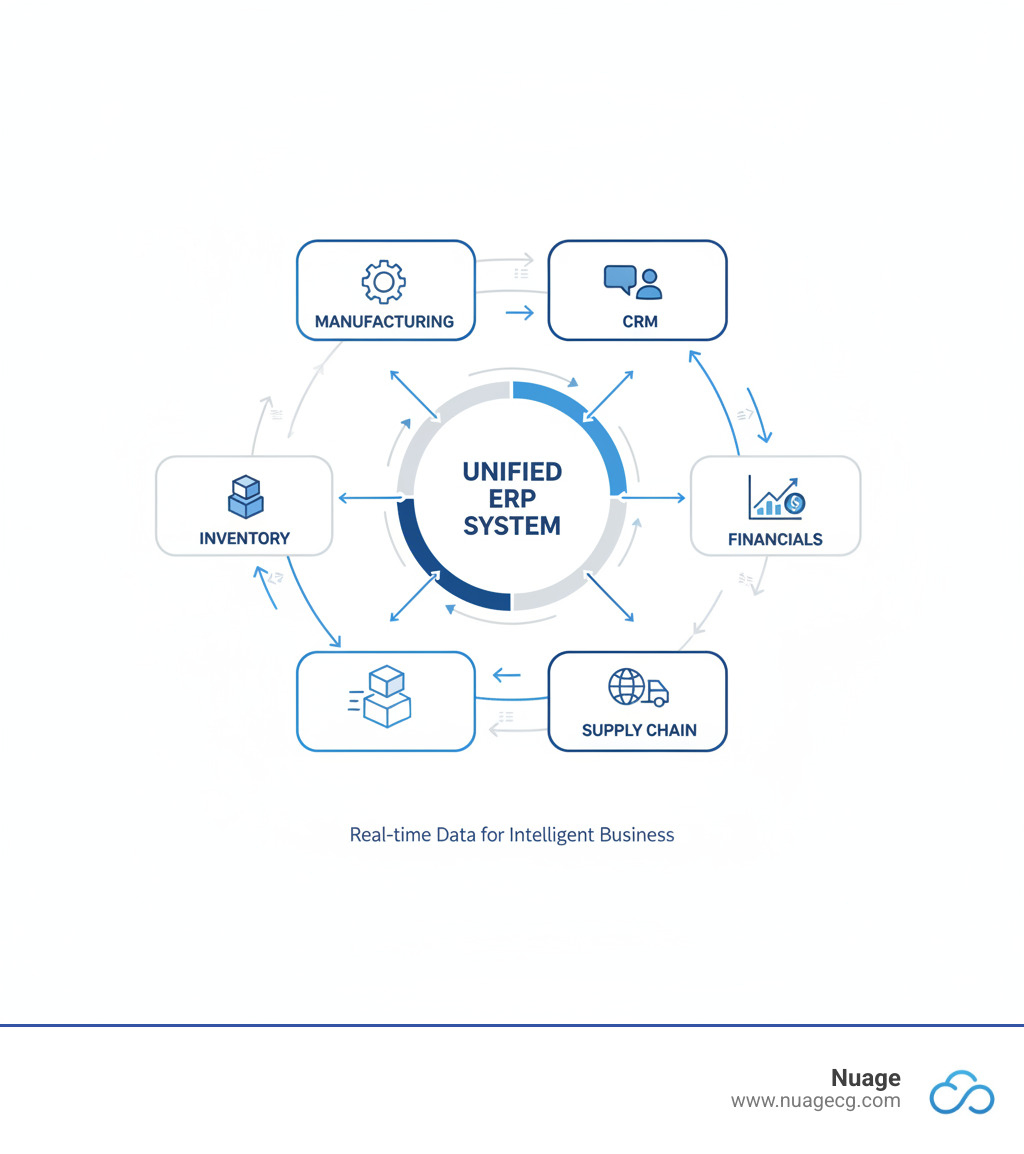

Creating a Unified Business with NetSuite

The true power of NetSuite Advanced Manufacturing is how it unifies your entire business. When manufacturing, financials, inventory, and sales all operate from the same data, you can make smarter, faster decisions.

This integration breaks down the walls between departments. Your sales team knows exactly when an order will be ready, and your production team understands the financial impact of their decisions. It creates a complete, real-time view of operations.

Integration with the Broader NetSuite ERP Ecosystem

Because NetSuite Advanced Manufacturing is built into the NetSuite platform, data flows automatically and in real time across your business:

- Financials: Production costs appear as they occur, enabling real-time variance analysis and accurate profitability reporting.

- Sales & CRM: Customer service teams can see the exact status of any order, leading to better communication and customer satisfaction.

- NetSuite Inventory Management: Stock levels are always accurate as materials are consumed and finished goods are completed, with seamless lot and serial traceability.

- Supply Chain: Gain full visibility from procurement to distribution, helping you manage lead times and optimize material flow.

- Order-to-Cash: The entire process accelerates as each step—from customer order to invoicing—is connected and automated.

Our NetSuite ERP Integration services ensure these connections are optimized for your specific business processes.

Advantages Over Disconnected Systems

Moving to a unified system like NetSuite Advanced Manufacturing offers a fundamental shift in how your business operates:

- Eliminate Data Silos: Everyone from the shop floor to the C-suite works from a single, accurate source of truth. No more conflicting spreadsheets or outdated reports.

- Reduce Manual Errors: Automation replaces manual data entry, reducing mistakes, rework, and time spent hunting for discrepancies.

- Accelerate Decisions: Real-time information allows you to respond to issues immediately, not days later when they’ve become costly problems.

- Lower Total Cost of Ownership (TCO): A single cloud solution eliminates multiple software licenses, servers, and complex integrations, potentially reducing TCO by 50% or more.

- Improve Productivity: Your team can focus on value-added work instead of chasing data or fighting system limitations. This is a core advantage of Cloud-based ERP Solutions for Manufacturing.

Frequently Asked Questions about NetSuite Advanced Manufacturing

Here are answers to the most common questions we hear from manufacturers evaluating NetSuite Advanced Manufacturing.

How does Advanced Manufacturing handle outsourced production?

NetSuite manages outsourced production by tracking subcontracted processes as part of your overall production flow. You can generate purchase orders for outsourced services, integrating external partners into your vendor management system. This provides visibility into the status and costs of outsourced work, ensuring it aligns with your production schedule and financial reporting. While direct MES integration with a third party may require custom work, the core capability to manage and track outsourced assemblies is built-in.

Can you customize shop floor travelers and reports?

Yes. Customizing standard reports, creating saved searches, and building dashboards in NetSuite is highly flexible and does not require deep technical knowledge. Customizing shop floor travelers, however, can be more complex. While basic changes are possible, adding specific fields often requires XML expertise. This is where an experienced partner can help tailor outputs to your exact needs. Our team has deep experience in NetSuite ERP Customization to assist with these modifications.

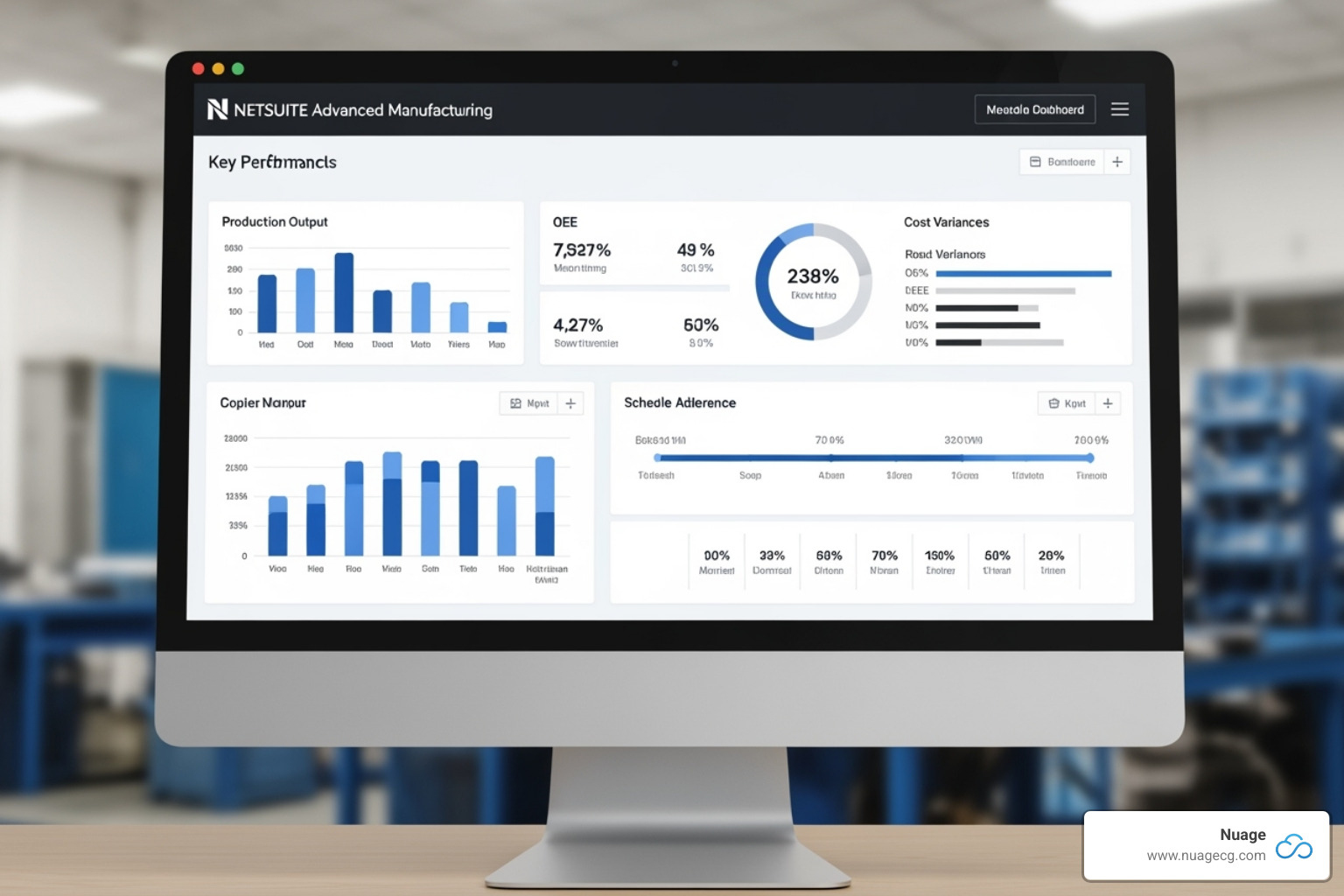

What kind of reporting is available?

NetSuite Advanced Manufacturing offers deep reporting capabilities for complete operational visibility.

- Operational Performance Reports: Track key metrics like production output, efficiency, and schedule adherence on real-time, role-based dashboards.

- Variance Analysis: Compare actual costs and production times against standards to quickly spot discrepancies and identify areas for improvement.

- Detailed Costing Reports: Break down material, labor, and overhead costs for granular profitability analysis by product or work order.

NetSuite also provides a Manufacturing Transaction data source for the SuiteAnalytics Workbook, allowing for advanced custom analysis. Our NetSuite Advanced Reporting Complete Guide explores these options in full detail.

Conclusion: Transform Your Operations with an Optimized Solution

The manufacturing world moves fast. NetSuite Advanced Manufacturing provides the unified data, real-time visibility, and operational control needed to turn good manufacturers into great ones. By integrating your shop floor, planning, inventory, and financials, you can stop fighting fires and start driving strategic growth.

We’ve covered how the solution’s Work Bench, finite capacity scheduling, and mobile capabilities eliminate the lag and errors of manual systems. But powerful software alone isn’t enough. Successful implementation and configuration are what open up true change.

At Nuage, we’ve spent over 20 years helping companies steer digital change. We don’t just sell software; we act as your NetSuite Optimization Engine. We take the time to understand your challenges and help you select, implement, and support the right NetSuite environment to deliver measurable results.

Whether you’re struggling with disconnected systems or inaccurate cost data, we can help. The manufacturers who thrive today are those who leverage data intelligently and accept continuous improvement. NetSuite Advanced Manufacturing provides the foundation; we help you build on it.

Ready to see what’s possible? Let’s discuss your specific needs and how we can transform your operations.

Learn more about our NetSuite solutions

Optimize Your NetSuite Manufacturing Setup

At Nuage, we specialize in NetSuite Optimization for manufacturing companies. Our team can help you maximize your Advanced Manufacturing module and improve production efficiency.

Watch our interview with Majid Abai, Chairman & CEO of Bay Cities Metal Products, where he shares how they optimized their NetSuite manufacturing processes:

Need ongoing support? Our Managed Services team provides continuous optimization and 24/7 Support for manufacturing operations.

Not sure if your NetSuite is optimized? Take our free NetSuite Scorecard to get a personalized assessment.

Want to see how we’ve helped other companies? Check out our customer success stories.

Last Updated: January 4, 2026