Manufacturing digital transformation: Crucial 2025

Why Manufacturing Digital Change is Your Path to Competitive Survival

Manufacturing digital change is the strategic integration of digital technologies across your entire manufacturing value chain. It’s not just about new software—it’s about rethinking your business model, processes, and culture to maximize revenue, reduce costs, improve quality, and increase flexibility.

Quick Answer: What You Need to Know

- Definition: Applying technologies like AI, IoT, and automation to maximize operational performance.

- Core Goal: Drive measurable business outcomes, not just implement technology for its own sake.

- Key Benefits: Potential for 30-50% reductions in downtime and 10-30% throughput increases.

- Investment Scale: Global spending is projected to reach $3.4 trillion by 2027.

- Success Rate: While 89% of large companies have initiatives, they’ve only captured 31% of the expected revenue lift.

The stakes are high. Unplanned downtime costs manufacturers $50 billion annually, and the gap between thriving and falling behind often comes down to how effectively you leverage your technology.

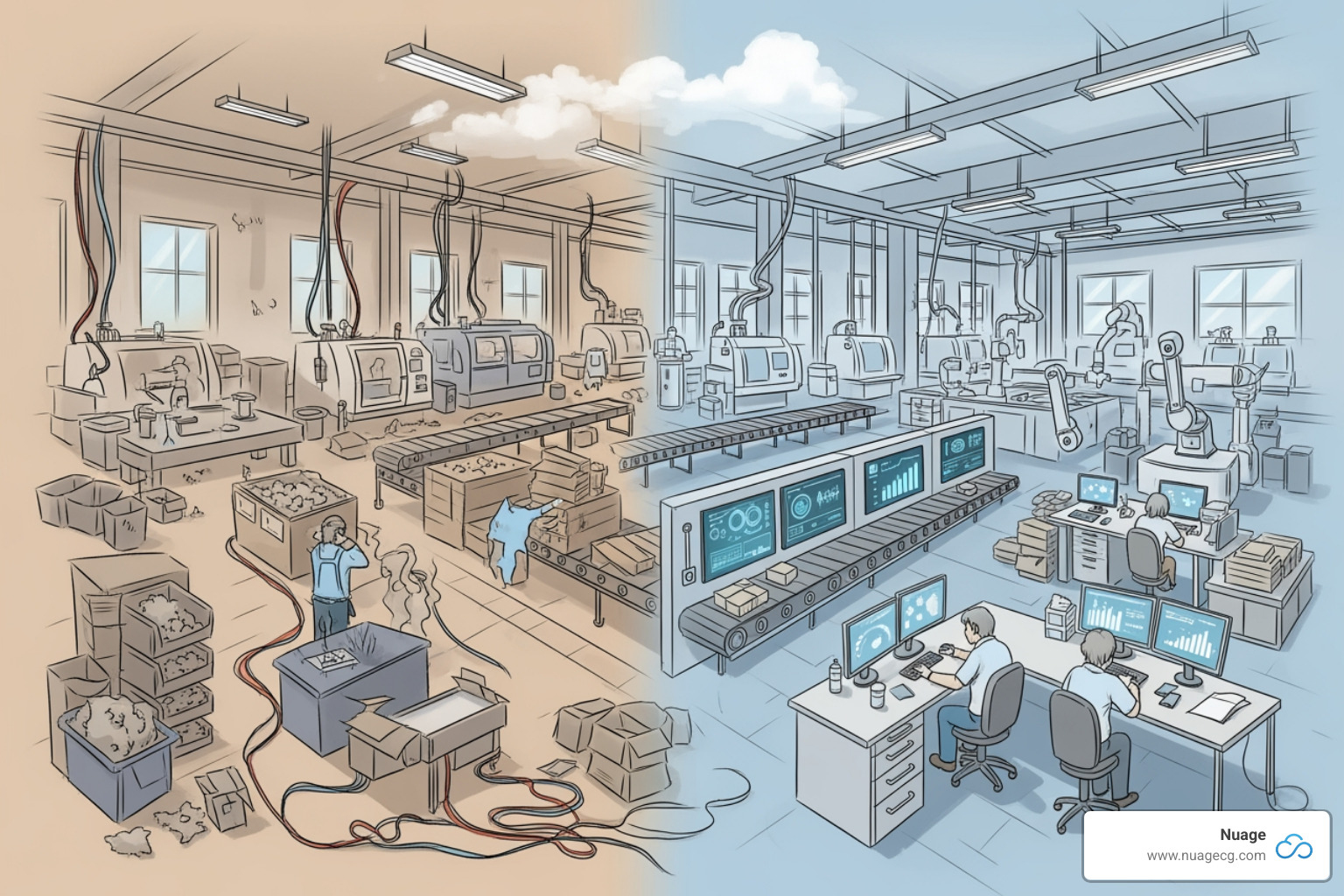

Many manufacturers have invested in powerful systems like NetSuite ERP but are only scratching the surface of their capabilities. Data remains siloed, processes are manual, and the promise of real-time visibility feels out of reach. This isn’t a technology problem—it’s a strategy problem. The path forward requires a harmony of People, Process, and Technology.

I’m Louis Balla, and for over 15 years, I’ve helped manufacturers bridge the gap between digital investments and business results. Through my work as CRO at Nuage and host of the Beyond ERP podcast, I’ve seen how the right approach—optimizing systems like NetSuite and focusing on strategic integration—transforms operations into industry leaders.

Manufacturing digital change terms to learn:

- what is advanced manufacturing

- NetSuite Advanced Manufacturing

- netsuite advanced manufacturing user guide

What is Manufacturing Digital Change and Why is it Crucial?

Manufacturing digital change is about weaving digital systems into your traditional processes to drive real performance improvements like efficiency gains and quality improvements. It’s not an IT project; it’s a business initiative that uses technology as a powerful enabler to overhaul production, decision-making, and your entire value chain.

With over 90% of manufacturing leaders believing digital change is vital for success, the question isn’t if you should transform, but how to do it effectively. Several powerful forces are driving this shift:

- Competitive Pressure: Two-thirds of manufacturers believe their competitors are ahead in digital maturity. In today’s market, someone is likely using digital tools to operate faster, cheaper, and more reliably than you.

- Customer Expectations: B2B customers now expect B2C experiences—customization, real-time updates, and self-service portals. Failing to deliver this responsiveness means losing business.

- Supply Chain Resilience: Recent global disruptions proved that digital tools are crucial for visibility and agility, allowing you to see problems coming and adjust before they become catastrophes.

- Labor Shortages: With skilled workers hard to find, digital tools like automation and AI can augment your existing workforce, making your team more effective and productive.

At Nuage, we see these drivers daily. Successful manufacturers apply the right technologies to maximize revenue, reduce costs, improve quality, and increase flexibility across their entire operation.

The Core Benefits for Modern Manufacturers

The payoff for manufacturing digital change is tangible and measurable. Key benefits include:

- Reduced Costs: Digitalization cuts operational expenses, minimizes waste, and optimizes resource allocation. One manufacturer saw a 20% sales increase and a 50% jump in eCommerce after implementing a new digital portal.

- Increased Throughput and Efficiency: McKinsey research shows manufacturers can achieve 10-30% throughput increases and 15-30% improvements in labor productivity.

- Improved Quality: AI algorithms and real-time monitoring lead to consistent, high-quality production, drastically reducing rework and associated costs.

- Data Visibility and Predictability: Integrating systems like your NetSuite ERP with shop floor tools creates a single view of your operation, enabling informed decisions and predictive maintenance.

- Improved Safety: Digital tools improve training and enable real-time monitoring, leading to fewer workplace accidents.

- Sustainability: Digital change helps reduce material and energy waste, enabling circular economy practices that are good for the planet and demanded by customers.

The bottom line is that companies with higher digital maturity report higher net profit and revenue growth. Being digital pays off.

The Current State of Digital Change in Manufacturing

The industry landscape is a mixed bag. A surprising 42% of manufacturers have not yet started their manufacturing digital change journey, creating a significant opportunity for those who act decisively to leapfrog competitors.

Investment is pouring into the sector. IDC predicts global digital change spending will hit $3.4 trillion by 2027, with discrete manufacturing leading all industries. However, there’s a major challenge: the “value capture gap.” While 89% of large companies have digital initiatives, they’ve only captured 31% of the anticipated revenue lift and 25% of expected cost savings.

This gap highlights the need for effective, strategic execution focused on business outcomes. This is where Nuage excels. We help manufacturers bridge this gap by optimizing existing systems, like a NetSuite implementation, to capture the value other companies are leaving on the table. The data is clear: companies with higher digital maturity win, not by spending more, but by deploying technology smarter.

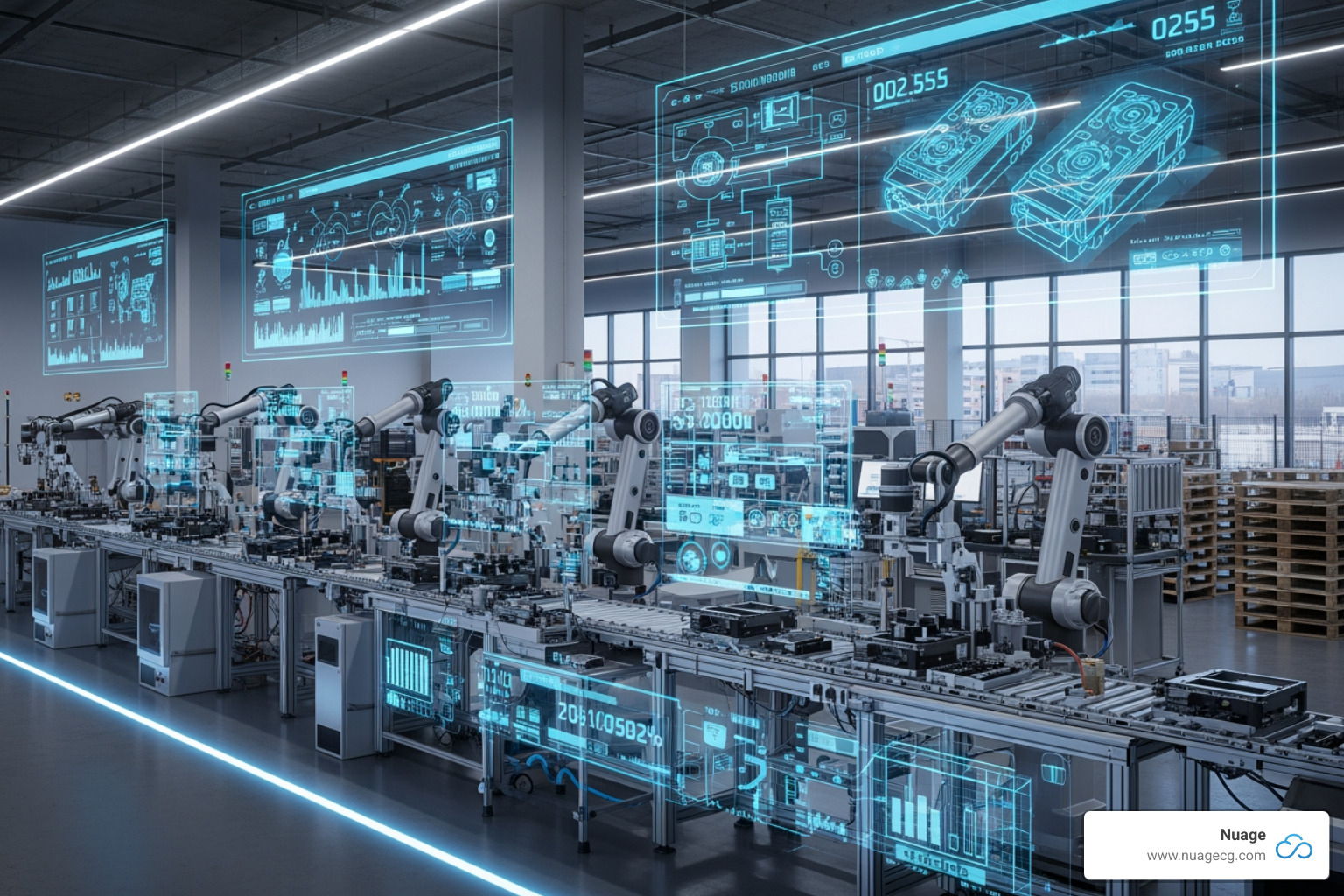

The Technology Powering the Smart Factory

Manufacturing digital change is powered by a collection of technologies that are reshaping factory floors today. The smart factory is an interconnected ecosystem where every machine and system communicates seamlessly.

- Industrial Internet of Things (IIoT) connects equipment and collects real-time data, providing unprecedented visibility into operations.

- Artificial Intelligence (AI) and Machine Learning (ML) analyze this data to spot patterns, predict outcomes, and optimize production.

- Digital Twins are virtual replicas of your factory or equipment, allowing you to simulate process changes and test workflows without disrupting physical operations.

- Robotics and Automation have evolved to include collaborative robots (cobots) that work alongside humans, handling repetitive tasks with precision.

- Augmented Reality (AR) and Virtual Reality (VR) are changing worker training and maintenance, overlaying instructions onto equipment or providing safe virtual practice environments.

- Cloud Computing provides the scalable infrastructure to store data, host applications, and enable remote collaboration.

Watch: NetSuite Manufacturing overview video

Foundational Systems: The Role of ERP

Many manufacturers invest in exciting technologies but fail to see value because their foundational systems are inadequate. Your Enterprise Resource Planning (ERP) system is the central nervous system of your operation. Without a robust ERP, other digital technologies operate in silos.

A modern ERP like NetSuite integrates data from procurement, production, sales, and finance into a single source of truth. This eliminates data silos and empowers your team to make better, faster decisions based on accurate information.

Key ERP functions include:

- Process Automation: Automating routine tasks like production scheduling and warehouse management reduces manual errors and saves time.

- Scalability: A cloud-based ERP grows with your business, whether you’re expanding into new markets or adding product lines, without requiring massive new investments.

- Financial Visibility: By consolidating financial data, your ERP provides a real-time view of your financial health, helping you identify cost-cutting opportunities and optimize cash flow.

- Supply Chain Management: Modern ERPs offer powerful tools for demand forecasting, inventory optimization, and logistics coordination to ensure production continuity.

We’ve spent years helping manufacturers optimize their NetSuite environments. Learn more about NetSuite ERP solutions and how a properly configured ERP can transform your operations. CRM platforms like Salesforce can also be integrated to connect customer demand and service with production and finance, extending visibility across the entire lead-to-cash lifecycle.

High-Impact Technologies for a Competitive Edge

Beyond a foundational ERP, certain technologies deliver immediate, measurable benefits. We recommend focusing initial investments in these areas:

- Predictive Maintenance: Addresses the $50 billion annual cost of unplanned downtime. IIoT sensors and AI monitor machine health to predict failures before they happen, allowing you to schedule maintenance proactively.

- AI-Powered Quality Control: Vision systems with AI algorithms inspect products with superhuman precision, catching defects early to reduce rework and improve customer satisfaction.

- Automation of Repetitive Processes: Collaborative robots can handle dangerous or dull tasks, freeing your skilled workforce to focus on problem-solving and creativity.

- Digital Performance Management & Real-Time Monitoring: Live dashboards provide immediate visibility into production metrics, quality, and equipment performance. This enables an agile response to changing conditions, preventing small issues from becoming major disruptions.

Building Your Roadmap: A Strategic Approach to Digital Change

Jumping into manufacturing digital change without a roadmap is a recipe for wasted time and money. Successful digital change isn’t about the technology itself; it’s about having a clear, value-driven strategy that aligns every initiative with real business outcomes. Sometimes, you need to slow down to go fast, taking time upfront to plan carefully and save months of wheel-spinning later.

McKinsey’s research on successful Industry 4.0 changes highlights several key principles: communicate a clear vision, secure leadership buy-in, formalize the value at stake, and design a multi-year roadmap. These principles work because they treat digital change as a business initiative, not an IT project.

Step 1: Define a Clear, Value-Driven Strategy

The foundation of your journey is a strategy focused on creating measurable value. Start by aligning every digital initiative with your core business goals, whether it’s reducing costs, improving quality, or speeding up time-to-market.

Next, conduct a network scan—a systematic review of your value chain to identify where digital solutions can deliver the most impact. These high-leverage areas become your priorities. Avoid “pilot purgatory” by focusing on two or three high-value use cases that you can implement fully before moving on.

This process requires securing leadership buy-in from the start. Digital change needs champions who can communicate the vision and maintain commitment. A lack of leadership support is a key reason why many companies have only captured 31% of expected revenue lift from digital transformation. Finally, develop a three- to five-year vision to ensure today’s decisions support your long-term goals.

Step 2: Overcoming Common Implementation Pitfalls

Even with a solid strategy, the path is filled with predictable obstacles. Knowing what to watch for is key to avoiding them:

- Siloed Implementation: Avoid implementing different, disconnected systems across plants. True value comes from integrated systems where data flows freely.

- Lack of Adaptation: Don’t force a one-size-fits-all solution. The best implementations customize a proven framework to fit your unique operational reality.

- Technology-Driven Approach: Deploy solutions to solve real business problems, not because they are trendy. Link every investment to a measurable outcome.

- Analysis Paralysis: Don’t wait for perfect information. “Accurate-enough” insights are usually sufficient to move forward and adjust as you learn.

- Poor Change Management: New systems require new workflows and skills. Without comprehensive training and clear communication, even the best technology will be underused.

Encouragingly, successful implementations can span just a few months when they are focused on specific, value-driven initiatives.

Step 3: Measuring Success and ROI

You can’t improve what you don’t measure. To know if your manufacturing digital change is working, you must track Key Performance Indicators (KPIs) that flow directly from your strategic goals.

Essential manufacturing KPIs include:

- Overall Equipment Effectiveness (OEE): A core productivity measure combining availability, performance, and quality.

- Downtime Reduction: Even modest improvements here create substantial value, given that unplanned downtime costs manufacturers $50 billion annually.

- Cost Savings: Track reductions in operational expenses, waste, energy, and rework.

- Throughput Increases: Measure if you are producing more with the same resources.

- Customer Satisfaction: Monitor improvements in delivery times, quality, and responsiveness.

Everything comes down to Return on Investment (ROI). Digital change is an investment that must deliver measurable financial returns. Rigorous ROI calculation and continuous monitoring are critical for success. At Nuage, we help optimize NetSuite implementations to make measuring these metrics straightforward, ensuring your digital investments pay off.

Navigating the Challenges on Your Journey

The path to manufacturing digital change is rarely smooth. There are significant obstacles that must be faced head-on to succeed.

Common challenges include:

- Legacy Systems: Integrating modern digital tools with decades-old machinery is a major barrier.

- Data Management: The explosion of data from IIoT can be overwhelming, often sitting in silos where it can’t be used effectively.

- Cybersecurity: As we connect more systems, we create new vulnerabilities that require robust protection for intellectual property and operational data.

- Skills Gap: Technology is evolving faster than many teams can adapt, creating a need for new skills in data analytics, AI, and digital operations.

- Budget Constraints: Justifying upfront investment can be tough, especially when the ROI isn’t clearly articulated.

These challenges are substantial, but they are not impossible. Every successful manufacturer has faced them; the difference lies in their approach.

Integrating Legacy Systems, Not Replacing Them

You don’t have to rip everything out and start from scratch. The most successful digital changes often happen in existing “brownfield” environments. The key is strategic integration, not wholesale replacement.

A phased integration approach—adding capabilities in stages—reduces risk and minimizes disruption. Digital Twin simulation is a powerful tool here, allowing you to create a virtual replica of your production process to test how new software will interact with legacy equipment before making physical changes. This ensures harmony between old and new systems.

The goal is interoperability, using middleware to create a bridge that lets different systems talk to each other. Your old equipment can communicate with your new NetSuite ERP, and legacy controls can feed data into modern analytics platforms. With the right approach, you can modernize your existing infrastructure without losing its inherent value.

The Human Element: Fostering Buy-in and a Digital Culture

Technology is just a tool; your people are the real engine of change. Without their buy-in, even the most sophisticated systems will fail to deliver their full potential.

Employee resistance is natural, but it can be overcome with clear communication and involvement. When people understand the “why” behind changes and see how new tools will make their jobs safer and more interesting, resistance often turns into enthusiasm. This requires a real investment in your people through comprehensive training and upskilling programs, fostering a culture of continuous learning.

Executive sponsorship is crucial for providing the top-down support that signals digital change is a strategic priority. But ultimately, the goal is to empower your workforce, not replace it. Tools like augmented reality for on-the-job training and digital dashboards for real-time insights help employees feel valued and supported by technology. Your experienced team members aren’t obstacles; they are the key to making digital change work.

The Future Outlook for Digital Change in Manufacturing

The pace of manufacturing digital change is accelerating, leading to fundamental shifts in how factories operate and how humans and machines interact.

Industry 5.0 is emerging, putting people back at the center of the equation. It focuses on creating symbiotic relationships between human creativity and machine precision, combining our adaptability with the tireless accuracy of automated systems. This human-centric approach creates more resilient, flexible, and innovative operations.

Future trends to watch include:

- Hyper-automation: Environments where every possible process is automated by combining AI, machine learning, and RPA. Factories become self-optimizing organisms that learn and adjust in real-time.

- Manufacturing-as-a-Service (MaaS): Similar to cloud computing, MaaS allows manufacturers to access specialized production capacity on demand, offering flexibility without massive capital investment.

- Closed-Loop Manufacturing: Self-correcting systems where sensors detect quality issues, AI identifies the root cause, and machines automatically adjust parameters without stopping production.

- The Industrial Metaverse: Immersive virtual environments used to train robots, simulate complex production scenarios, and enable global collaboration, accelerating innovation as highlighted by McKinsey’s research.

- Sustainability as a Requirement: Digital technologies are key to achieving carbon reduction targets. Smart energy management, digital twins for waste reduction, and transparent supply chains are now core components of a modern digital strategy.

Global digital change spending is projected to reach $3.4 trillion by 2027, signaling that this is the new foundation of competitive manufacturing. These technologies work best together, with a system like NetSuite ERP acting as the central nervous system. The manufacturers who thrive will be those who strategically integrate these innovations to deliver measurable business value.

Conclusion

The landscape of manufacturing digital change is a journey of continuous improvement, not a one-time project. It’s the path from reactive firefighting to predictive operations, and it’s the difference between capturing market share and falling behind.

The winners in this new era are not necessarily those spending the most on technology, but those who are most strategic about its deployment. They focus on measurable business outcomes—reduced costs, increased throughput, and improved quality—by aligning technology with clear goals.

However, technology alone is not enough. The human element is what turns digital investments into business results. Your workforce must be empowered by new tools and equipped with the skills to thrive in a digital environment.

At Nuage, we’ve spent over 20 years helping manufacturers bridge the gap between their technology investments and actual results. We see the frustration when powerful systems like NetSuite are underused and data remains trapped in silos. That’s why we act as your NetSuite Optimization Engine.

We partner with you to align your technology with your strategic goals, break down system walls, and focus on use cases that deliver measurable value. We are there from selection through implementation and beyond to ensure your digital investments pay off.

The future of manufacturing is being built now, with companies investing trillions to stay competitive. The question is whether you’ll capture the full value or join the majority who have realized only a fraction of the expected returns.

Let’s make sure you’re in the winning group. Future-proof your operations with NetSuite.