Why Inventory Management Optimization Matters More Than Ever

Inventory management optimization is the strategic process of holding the right amount of stock to meet customer demand while minimizing costs. It moves beyond basic tracking to use data analytics, forecasting, and technology for smarter decisions about what to stock, when to reorder, and where to allocate inventory.

Quick Answer: What is Inventory Management Optimization?

- Balance supply and demand – Keep just enough inventory to meet customer needs without overstocking

- Minimize total costs – Reduce holding costs, storage expenses, and waste from obsolescence

- Improve cash flow – Free up working capital tied up in excess inventory

- Improve service levels – Prevent stockouts that lead to lost sales and unhappy customers

- Use data-driven decisions – Leverage forecasting, analytics, and automation to optimize stock levels

The stakes have never been higher. Research firm IHL estimates that the cost of overstocks and stockouts worldwide neared $1.8 trillion in 2023. For most businesses, inventory is one of the largest capital investments. Yet many struggle with unpredictable demand, complex supply chains, and limited visibility.

Behind the scenes of same-day delivery and readily available products lies an incredibly complex inventory management system. The good news? Modern inventory management optimization transforms this complexity into a competitive advantage. By combining proven techniques with advanced technologies like AI and cloud-based ERP systems, businesses can see inventory reductions of 10-35% and significantly improved service levels.

This guide walks you through everything you need to know, from fundamentals and techniques to technology and implementation. You’ll find actionable strategies to turn your inventory into a strategic asset.

I’m Louis Balla, CRO and partner at Nuage. I’ve spent over 15 years helping companies optimize their supply chain operations, particularly through inventory management optimization using platforms like NetSuite. I’ve seen the transformative results when businesses get inventory optimization right.

Understanding the Fundamentals of Inventory Optimization

Inventory management and inventory management optimization are not the same. Inventory management is the tactical process of tracking, storing, and ordering stock. Optimization is the strategic thinking behind those decisions—the how and why that turns inventory into a profit driver.

| Feature | Inventory Management | Inventory Optimization |

|---|---|---|

| Key Differences | Tracking, storing, and ordering inventory | Strategically balancing stock levels for maximum profit and customer satisfaction |

| Strategic vs. Tactical | Tactical: Focus on operational efficiency and control | Strategic: Focus on profit margins, risk mitigation, and competitive advantage |

| Scope | Broader process of ordering, storing, and using inventory | A component of inventory management, specifically focused on finding optimal stock levels |

Inventory management ensures you have products on your shelves. Inventory management optimization ensures you have the right products, in the right quantities, at the right time, and at the right cost.

The Core Goals of Optimizing Your Inventory

Optimizing inventory is like walking a tightrope between having too much stock (which eats up cash) and too little (which leads to frustrated customers). The primary goals are:

- Maximizing profitability: Minimizing carrying costs and avoiding lost sales from stockouts directly boosts your bottom line.

- Minimizing costs: This includes reducing holding costs (storage, insurance) and the hidden expenses of stockouts, like rush shipping or lost customer trust.

- Improving cash flow: Optimization frees up working capital tied up in excess inventory, making your business more agile and financially healthy.

- Improving customer satisfaction: Having the right products available when customers want them builds loyalty and trust.

- Reducing waste and obsolescence: Optimization helps you predict when products might become obsolete, allowing you to sell them before they turn into dead stock.

Key Benefits for Your Business

Effective inventory management optimization creates positive effects throughout your organization:

- Reduced holding costs: Less inventory sitting around means lower overhead for storage, insurance, and security.

- Fewer stockouts: Consistent product availability improves the customer experience and prevents lost sales.

- Increased operational efficiency: Data-driven, automated processes reduce manual errors and free up your team for more strategic work.

- Improved supply chain resilience: Smart inventory buffers and diversified supplier relationships help you adapt quickly to disruptions.

Proper inventory management delivers numerous benefits that lead to long-term growth. Companies using NetSuite ERP systems often see these benefits multiply as their data and processes become more integrated.

Types of Inventory to Consider

A comprehensive strategy considers every form of inventory. Using a soup company as an example:

- Raw materials: The basic ingredients purchased from suppliers (e.g., vegetables, spices, cans). Optimization ensures they are available for production without spoiling.

- Work-in-progress (WIP): Partially finished goods still in production (e.g., soup being cooked or cooled). Optimizing WIP can reduce production bottlenecks.

- Finished goods: Completed products ready for customers (e.g., canned soup in the warehouse). This requires careful balancing to meet demand without overstocking.

- Maintenance, repair, and operating (MRO) supplies: Items that keep operations running but aren’t part of the final product (e.g., cleaning supplies, spare parts for machinery).

Proven Inventory Optimization Techniques and Strategies

Truly optimizing inventory requires practical, battle-tested strategies. Think of these techniques as tools in a toolkit; the most successful companies combine multiple approaches for a comprehensive inventory management optimization system.

- ABC Analysis: This technique categorizes inventory based on value. “A” items are high-value products that represent the largest capital investment. “B” items are mid-range, and “C” items are low-value. Following the 80/20 rule, this method focuses optimization efforts on the most critical items.

- Demand Forecasting: This is the process of predicting what customers will want and when. Without accurate forecasts, businesses are either overstocking and tying up cash or understocking and losing sales.

- Just-in-Time (JIT): A lean approach where goods are ordered and received only when needed for production or sale. This minimizes holding costs but requires reliable suppliers and stable demand.

- Economic Order Quantity (EOQ): A formula that balances holding, ordering, and shortage costs to determine the ideal quantity to order at one time.

- Safety Stock Calculation: This determines the buffer inventory needed to prevent stockouts from unexpected demand spikes or supplier delays.

- SKU Rationalization: A regular review of the product catalog to eliminate underperforming or redundant Stock Keeping Units (SKUs), reducing complexity and costs.

Demand Forecasting: Predicting Customer Needs

If inventory management optimization is a house, demand forecasting is the foundation. It relies on several inputs:

- Historical data analysis: Past sales trends, seasonality, and promotional impacts help identify patterns that are likely to repeat.

- Market trends: Broader economic indicators, industry shifts, and competitive dynamics all influence future demand.

- Predictive analytics: Advanced statistical models and machine learning can generate more accurate forecasts, especially for volatile or new products.

- Seasonality: Accounting for predictable cyclical fluctuations, from obvious ones like winter coats to subtle ones like back-to-school shopping.

The Amazon Effect has shifted consumer expectations toward fast, convenient delivery. This requires incredibly precise forecasts, as there is little room for error. A modern ERP system like NetSuite can integrate these inputs for more accurate, real-time predictions.

Balancing Stock with JIT and Safety Stock

Inventory management optimization isn’t about eliminating inventory; it’s about finding the optimal amount by balancing lean principles with protective buffers.

Just-in-Time (JIT) inventory minimizes what you hold by receiving goods only when needed. This reduces storage costs and waste but is vulnerable to disruptions.

That’s where safety stock comes in. It’s the extra inventory held as insurance against uncertainty, like a supplier delay or a sudden demand spike. This cushion prevents stockouts and disappointed customers.

Reorder points work with safety stock. These are predetermined inventory levels that automatically trigger a new order, ensuring replenishment arrives before stock runs out.

The real skill is balancing service levels against holding costs. It’s not feasible to have 100% availability for every item. Smart optimization involves using higher safety stock for critical “A” items while allowing for occasional, planned stockouts on low-selling “C” items. This balanced approach optimizes investment while maintaining customer satisfaction where it matters most.

The Role of Technology in Modern Inventory Management Optimization

Optimizing inventory with spreadsheets is like navigating with a paper map in a world with GPS. In today’s business environment, technology isn’t just helpful for inventory management optimization; it’s essential.

Key technologies include:

- AI and Machine Learning: Revolutionizing demand forecasting by spotting subtle patterns and predicting supply chain disruptions.

- Inventory Management Software: Providing real-time visibility, automating tasks, and generating insights.

- Enterprise Resource Planning (ERP) Systems: Systems like NetSuite connect inventory with all other business functions—sales, finance, manufacturing—for a single, unified view.

- IoT Devices: Sensors and RFID tags track inventory movement automatically and accurately.

- Cloud Computing: Tying it all together, allowing teams anywhere to access the same real-time data and collaborate seamlessly.

Leveraging Software for Seamless Optimization

The right software transforms inventory management optimization into a smooth, integrated process.

- ERP Integration: A robust ERP system like NetSuite creates a single source of truth. Sales forecasts automatically inform purchasing, and warehouse updates are instantly reflected in financial reports. Everyone works from the same playbook.

- Real-time Tracking: Knowing where every item is, right now. This allows for confident customer service and immediate response to demand spikes.

- Automation: Handling repetitive tasks like triggering reorders and updating stock levels. This frees up teams for strategic work and improves accuracy.

NetSuite’s ERP solutions excel at multi-location inventory management, making it ideal for businesses operating across California, Florida, or globally. The system can automatically balance stock between locations based on demand. Additionally, integrating data from platforms like Salesforce provides customer insights that directly inform inventory decisions.

The Future: AI-Powered Inventory Management Optimization

Artificial Intelligence is rapidly becoming a must-have for inventory management optimization.

- Generative AI: These systems can model complex scenarios, simulate market reactions, and suggest creative solutions to inventory challenges. A reported 89% of executives are including generative AI in their key automation investments.

- Predictive Replenishment: AI algorithms analyze vast datasets—historical sales, market trends, weather, social media buzz—to generate highly accurate reorder points and quantities.

- Anomaly Detection: AI acts as a 24/7 watchdog, instantly spotting unusual patterns like a sudden demand spike or supply delay. This allows for proactive responses to potential problems.

Advanced research on stochastic optimization continues to push boundaries, developing models that optimize inventory even in the face of volatility. The future of inventory management is intelligent, automated, and data-driven.

Implementation: Challenges, Metrics, and Best Practices

Implementing inventory management optimization is a process of continuous tuning. Understanding common problems, key metrics, and best practices makes the process manageable.

Overcoming Common Optimization Challenges

Even the best strategies face real-world obstacles. Recognizing them is the first step to overcoming them.

- Demand Volatility: Customer preferences, trends, and economic conditions can shift unexpectedly, making forecasts difficult.

- Supply Chain Disruptions: Global events, natural disasters, or supplier issues can create chaos in a well-planned inventory system.

- Data Inaccuracy: Inconsistent or incomplete data leads to flawed decision-making. Garbage in, garbage out.

- Technology Integration: Making new software work with existing ERP, CRM, or warehouse systems can be complex and requires technical expertise.

In an environment of unprecedented competition, every efficiency gain from optimization can be a deciding factor.

Essential Metrics for Measuring Success

To know if your efforts are working, you must measure the right things. These KPIs provide a clear picture of your inventory health:

- Inventory Turnover Ratio: Shows how quickly you sell and replace inventory. A higher ratio generally indicates efficiency and lower holding costs.

- Fill Rate: The percentage of customer orders you can fulfill immediately from stock. This is a direct measure of customer satisfaction.

- Days of Inventory on Hand (DOH): The average number of days it takes to sell through your inventory. A low number is good, but too low risks stockouts.

- Carrying Cost of Inventory: All expenses related to holding inventory, including storage, insurance, taxes, and obsolescence risk.

- Stockout Rate: The percentage of orders you couldn’t fulfill due to a lack of product. This should be as close to zero as possible for key items.

Balancing these metrics is the art of inventory management optimization.

Best Practices for Sustainable Inventory Management Optimization

Optimization is an ongoing commitment, not a one-time project.

- Continuous Improvement: Regularly analyze KPIs, identify weak spots, and adjust your strategies. Markets and customer preferences are always changing.

- Strategic Supplier Relationships: Build collaborative partnerships with suppliers. Share forecasts, communicate openly, and diversify your supplier base to mitigate risk.

- Adopt Lean Practices: Constantly look for ways to minimize waste. Proactively manage Slow and Obsolete Stocks (SLOB) through promotions or returns.

- Data-driven Decisions: Replace gut feelings with decisions backed by solid data. Modern NetSuite ERP solutions provide the analytics and forecasting tools needed for this.

- Establish a quarterly inventory budget: Treat inventory as a major financial investment that requires its own planning and accountability.

Frequently Asked Questions about Inventory Optimization

What are the first steps to optimizing inventory?

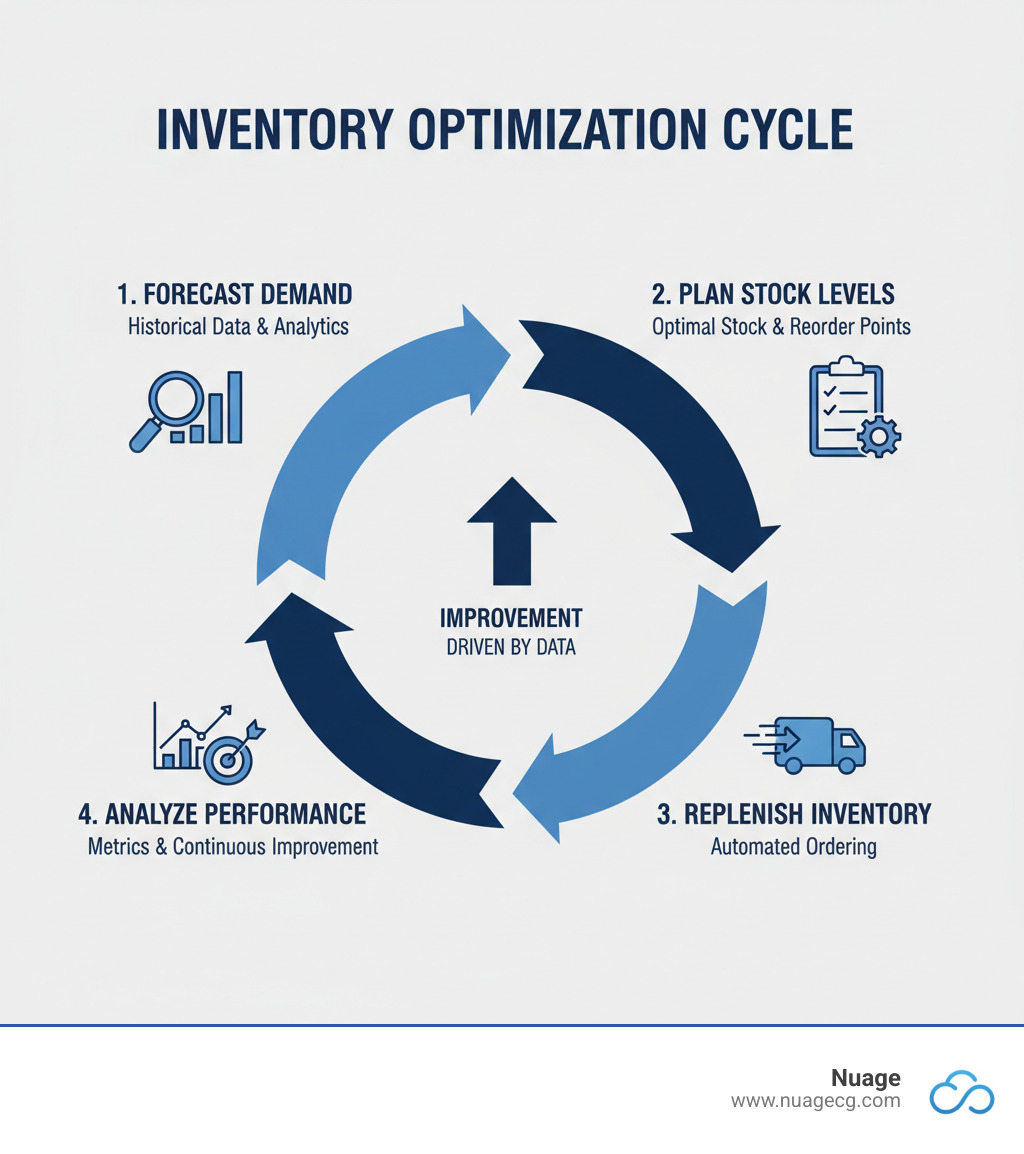

Starting your inventory management optimization journey can be broken down into four key steps:

- Analyze historical sales data: Dive into past sales figures to understand product performance and identify seasonal patterns or trends.

- Set optimal stock levels: Use your analysis to determine reorder points and order quantities for each product, balancing service levels with carrying costs.

- Leverage automated inventory systems: Use software to automate tracking, reordering, and stock level updates. This saves time and reduces costly human errors.

- Continuously monitor and adjust: Optimization is not a one-time fix. Regularly review key metrics and adapt your strategy to market shifts, supply chain changes, and customer behavior.

What is the difference between deterministic and stochastic models?

These are two main mathematical approaches to inventory optimization:

- Deterministic models assume everything is predictable and constant (demand, lead times, costs). They work well for stable products and are simpler to implement, making them a good starting point.

- Stochastic models account for real-world uncertainty and variability. They use probability to forecast a range of possible outcomes for demand and supply. In today’s volatile markets, stochastic approaches are increasingly valuable.

Advanced research in stochastic optimization is helping companies model and optimize inventory in large-scale, dynamic supply chains.

How often should I review my inventory strategy?

The ideal frequency involves a mix of continuous monitoring and periodic deep dives.

- Continuously monitor key metrics: Use dashboards and alerts for daily or weekly check-ins on metrics like fill rate and stockout rates. This helps you catch immediate issues.

- Conduct formal reviews quarterly: A quarterly review is the time to analyze broader trends, adjust your overall strategy, and realign your inventory budget. This is when you ask bigger questions about forecasting methods and SKU performance.

- Review immediately after significant changes: Don’t wait for a quarterly review if a major event occurs. New product launches, major market shifts, or supply chain disruptions all warrant an immediate review and adaptation of your inventory management optimization approach.

Conclusion: Transform Your Inventory into a Strategic Asset

Inventory management optimization is not just an operational task; it’s a fundamental shift in how you run your business. We began by discussing the $1.8 trillion lost to overstocks and stockouts—a figure that represents a massive opportunity for companies that get optimization right.

Throughout this guide, we’ve seen how optimization delivers tangible benefits: improved cash flow, reduced holding costs, and better customer satisfaction. We’ve explored techniques like ABC analysis and demand forecasting, and we’ve seen how modern technology—from ERP systems like NetSuite to AI-powered analytics—makes it all possible.

The goal is to move from being reactive to proactive. Instead of constantly fighting fires, you can anticipate needs, plan strategically, and make decisions based on data. The future of inventory is intelligent and automated, and companies that accept this will pull far ahead of the competition.

At Nuage, we have spent over 20 years guiding companies through this exact digital change. As your NetSuite Optimization Engine, we partner with you to select, implement, and support the right solutions for your unique challenges. We don’t just sell software; we ensure your NetSuite environment evolves with your business.

Your inventory doesn’t have to be a burden. With the right strategies, tools, and partners, it becomes a powerful strategic asset that drives profitability and sustainable growth.

Ready to make that change? Partner with a NetSuite Optimization Engine to implement these strategies and find what optimized inventory can do for your business.