From Spreadsheets to a Single Source of Truth

Food enterprise resource planning is a specialized software solution that integrates all aspects of food and beverage operations – from recipe management and production scheduling to inventory tracking and regulatory compliance – into one unified system.

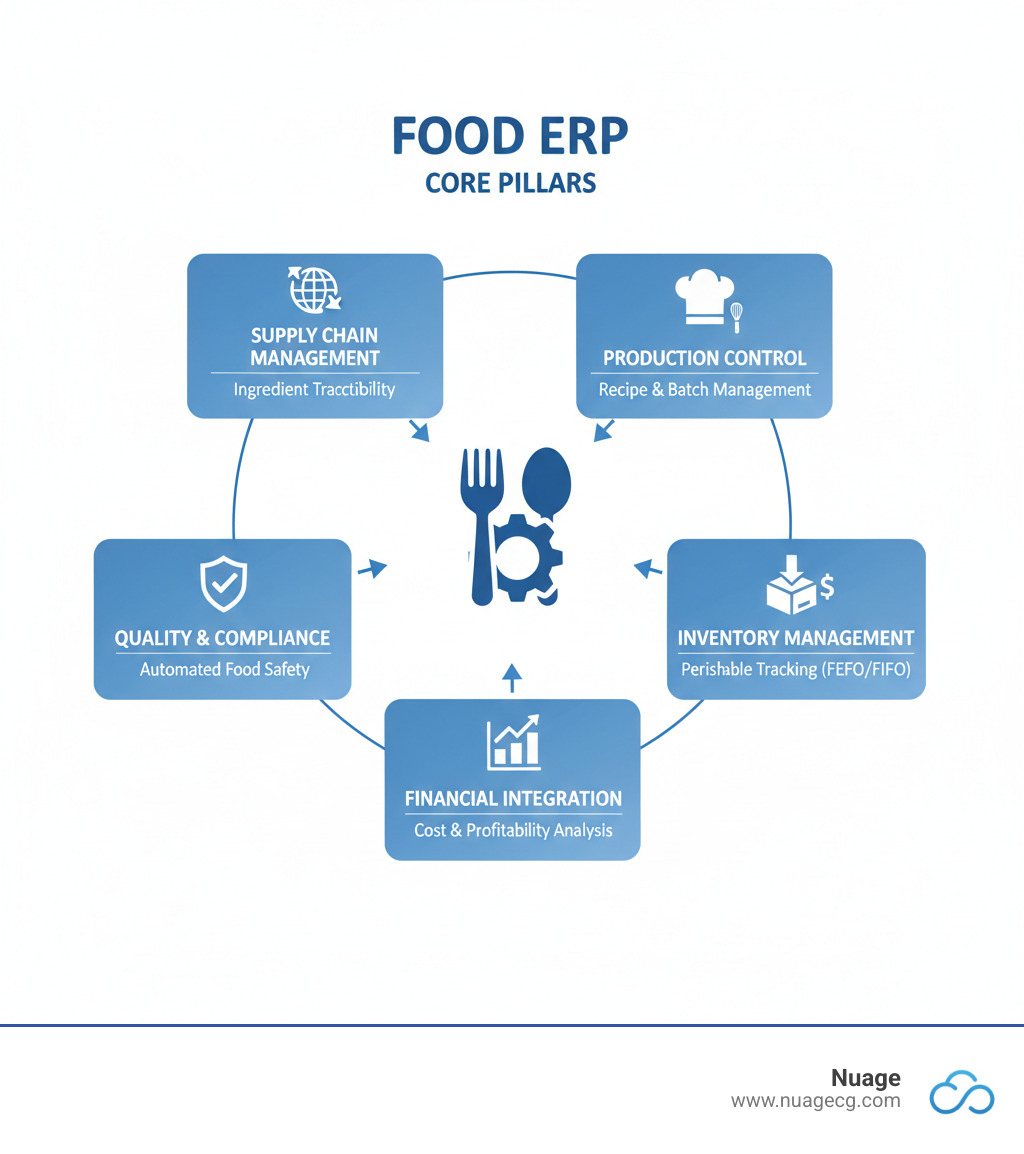

What Food ERP Includes:

- Supply Chain Management – Track ingredients from farm to fork

- Production Control – Manage recipes, batches, and yield optimization

- Quality & Compliance – Automate HACCP, FSMA, and food safety protocols

- Inventory Management – Handle perishables with FEFO/FIFO logic

- Financial Integration – Real-time cost tracking and profitability analysis

The food and beverage industry faces unique challenges that generic ERP systems simply can’t handle. Perishable inventory expires quickly. Regulatory pressure from agencies like the FDA demands precise traceability. Consumer transparency requirements mean every ingredient must be tracked and verified.

The market recognizes this need – the global food ERP market is projected to reach USD 2.5 billion by 2030, growing at 9.8% annually. This growth reflects a fundamental shift from manual chaos to integrated control.

Companies using food-specific ERP solutions report 15% increases in operational efficiency, 20% reductions in inventory costs, and 10% decreases in waste. The difference between managing with spreadsheets versus a proper food ERP system isn’t just operational – it’s competitive survival.

I’m Louis Balla, and over my 15+ years in digital change and supply chain experience, I’ve seen how food enterprise resource planning systems transform operations from reactive firefighting to proactive management. Through my work building and installing third-party applications for NetSuite, I understand the specific challenges food businesses face when trying to scale their operations efficiently.

The Business Case: Why Generic ERPs Don’t Cut It for Food & Beverage

Picture this: you’re trying to track a batch of organic tomatoes from farm to finished sauce, but your generic ERP system treats them like widgets with no expiration date, no allergen information, and no way to quickly trace them if there’s a recall. Sound familiar? You’re not alone.

The harsh reality is that generic ERP systems simply weren’t built for the unique challenges of food and beverage operations. When you’re managing perishable inventory, complex recipes, and strict regulatory requirements, a one-size-fits-all approach creates more problems than it solves.

Without a specialized system, food companies often find themselves drowning in inefficient processes. Manual data entry becomes the norm. Information gets trapped in silos across different departments. Your production team can’t see what inventory is available, while your procurement team doesn’t know what’s actually needed on the floor.

Limited traceability becomes a nightmare when you need it most. Imagine getting a call about a potential contamination issue and having to spend hours or even days figuring out which products are affected and where they went. That’s not just stressful – it’s dangerous and expensive.

The compliance risks are equally concerning. Food businesses must steer a maze of regulations from the FDA, USDA, and other agencies. Generic systems often lack the built-in functionality to handle HACCP protocols, allergen management, or the detailed documentation required for audits.

And let’s talk about waste. Without proper tracking of expiration dates and shelf life, companies often find increased waste from products that expire before they can be sold or used. It’s money literally going into the dumpster.

Inaccurate costing is another pain point. When you can’t properly track the true cost of ingredients, labor, and overhead for each product, how can you price effectively or identify your most profitable items?

Why Your Business Needs a Specialized Food Enterprise Resource Planning Solution

Here’s where things get exciting. A specialized Food enterprise resource planning solution changes everything because it understands your business at its core.

Companies that make the switch see an operational efficiency increase of 15% almost immediately. Why? Because these systems are designed specifically for food operations. They understand that recipes need to be scaled, that ingredients have shelf lives, and that allergen information must travel with every batch.

The cost reduction benefits are substantial. When your system can automatically rotate stock using FEFO (First Expired, First Out) logic, track waste patterns, and optimize inventory levels, you’re not just saving money – you’re improving your entire operation’s profitability.

Improved customer service naturally follows. With better visibility into inventory and production schedules, you can give customers accurate delivery dates and actually meet them. We’ve seen businesses achieve on-time delivery improvements of up to 25% after implementing the right food ERP system.

Perhaps most importantly, you gain access to real-time data for improved decision-making. Instead of waiting for end-of-month reports, you can see what’s happening in your operation right now and adjust accordingly.

The Tangible Benefits of a Modern Food ERP

Let’s talk numbers that matter to your bottom line.

Reduced inventory costs of up to 20% might sound too good to be true, but it’s not. When your system can accurately forecast demand, track shelf life, and optimize ordering patterns, you naturally carry less excess inventory while avoiding stockouts.

Waste reduction of 10% happens when your system tracks expiration dates, monitors quality metrics, and helps you use older inventory first. For a food business, that percentage represents real money saved and sustainability goals achieved.

Streamlined operations become the new normal. Production scheduling integrates with inventory management. Quality control connects to batch tracking. Financial reporting happens automatically. Everything works together instead of fighting against each other.

Scalability for growth means your system grows with you. Whether you’re adding new product lines, expanding to new markets, or increasing production volumes, a robust food ERP adapts to support your ambitions.

The competitive advantage is perhaps the most valuable benefit. While your competitors struggle with manual processes and disconnected systems, you’re operating with precision, speed, and confidence.

Modern platforms like NetSuite are specifically designed to handle these complex food industry requirements, offering the specialized functionality that generic systems simply can’t match.

For more insights into how comprehensive ERP systems can transform your operations, check out more info about NetSuite benefits to see specific examples of how these systems drive real business results.

Core Functionalities of a Food Enterprise Resource Planning System

Picture your Food enterprise resource planning system as the master chef of your operation – orchestrating every ingredient, timing, and technique to create something extraordinary. Unlike a generic ERP that treats your artisanal cheese the same as a steel bolt, a specialized food ERP understands the delicate dance of perishables, regulations, and consumer expectations.

Mastering Compliance and Food Safety

When it comes to food safety, there’s no room for “oops.” Your Food enterprise resource planning system becomes your vigilant food safety partner, watching over every step from farm to fork.

The foundation starts with lot and batch tracking. Think of it as your product’s DNA – every ingredient, every batch, every step is recorded with surgical precision. When something goes wrong (and in food, it’s not if but when), you can trace the problem back to its source in minutes, not days. This capability transforms terrifying mock recalls from company-ending disasters into manageable exercises.

Meeting Food and Drug Administration (FDA) requirements becomes second nature when your system automatically handles HACCP, SQF, and FSMA compliance. Instead of drowning in paperwork, your team focuses on what matters – making great food safely.

Allergen management deserves special attention in today’s world. Your ERP tracks every potential allergen through production, preventing cross-contamination and ensuring accurate labeling. No more late-night panic calls about whether that batch of cookies might have touched nuts.

Quality control automation takes the guesswork out of consistency. From incoming ingredient inspections to final product checks, your system maintains standards automatically, creating certificates of analysis and flagging deviations before they become problems.

Optimizing Your Kitchen and Production Floor

Your production floor is where the magic happens, and a specialized Food enterprise resource planning system ensures that magic is repeatable, profitable, and efficient.

Recipe and formula management centralizes your culinary secrets while keeping them secure. Whether you’re scaling grandma’s sauce recipe from 10 gallons to 1,000 or adjusting for seasonal ingredient variations, your system handles the math while preserving the taste. Every nutritional fact, allergen warning, and ingredient specification stays perfectly aligned.

Batch scaling and yield optimization work together like a perfectly timed kitchen brigade. Need to double production for a big order? Your system recalculates everything – ingredients, timing, equipment needs – while tracking actual yields against projections. Over time, this data reveals opportunities to squeeze more value from every ingredient.

Production scheduling becomes your head chef, balancing equipment capacity, staff schedules, and ingredient availability. It predicts bottlenecks before they happen and optimizes changeovers to minimize downtime. The result? Smoother operations and happier teams.

Understanding true profitability requires accurate Cost of Goods Sold (COGS) tracking. Your system captures every cost – from the obvious ingredients to the subtle overhead expenses – giving you real-time visibility into margins. This granular insight helps you price products correctly and identify your most profitable items.

The emerging concept of Culinary Resource Planning (CRP) takes this specialization even further. While traditional ERP handles general business processes, CRP dives deeper into culinary-specific needs like recipe versioning, menu engineering, and waste optimization. It’s like having a digital sous chef that never forgets a detail.

Streamlining the Supply Chain from End to End

Your supply chain extends from the farm where ingredients grow to the moment customers enjoy your products. A robust Food enterprise resource planning system provides visibility and control across this entire journey.

Inventory management in food requires special intelligence. Your system understands FEFO (First-Expired, First-Out) and FIFO (First-In, First-Out) methodologies, automatically rotating stock to minimize spoilage. It handles catch weights for products sold by the pound and manages the complex dance of perishable goods with different shelf lives.

Demand forecasting transforms historical data into future insights. By analyzing sales patterns, seasonal trends, and market factors, your system predicts what customers will want and when. This foresight enables smarter purchasing decisions and reduces both stockouts and waste.

Procurement automation streamlines vendor relationships and purchase orders. Your system tracks supplier performance, manages contracts, and ensures you’re getting quality ingredients at competitive prices. It even handles the paperwork for organic certifications and other special requirements.

Integrated Warehouse Management (WMS) optimizes every square foot of storage space. From receiving dock to shipping bay, your system guides workers through the most efficient paths, maintains accurate inventory counts, and ensures proper storage conditions for different product types.

Modern food operations rely heavily on Global Standards 1 (GS1) barcode support along with other standards like Code 128 and Code 93. This technology enables lightning-fast tracking of stock-keeping units (SKUs) and batches throughout your facility, reducing errors and improving traceability.

The beauty of a specialized food ERP lies in how these functionalities work together seamlessly. When your production system talks directly to inventory management, which connects to quality control, which feeds into compliance reporting, you create a symphony of efficiency that generic systems simply can’t match.

Choosing and Implementing Your Food ERP Solution

Selecting and implementing a Food enterprise resource planning system is like planning the perfect dinner party. You wouldn’t just throw ingredients together and hope for the best – you’d carefully plan your menu, consider your guests’ preferences, and prepare everything step by step. The same thoughtful approach applies to choosing your ERP solution.

Key Considerations for Implementing a Food Enterprise Resource Planning System

Think of this process as building your dream kitchen. You wouldn’t buy the first equipment you see – you’d consider your cooking style, space, and long-term culinary goals. Implementing a Food enterprise resource planning system requires the same careful consideration.

Assessing your business needs is where everything begins. Are you a small artisan bakery struggling with ingredient traceability? Or perhaps a large-scale manufacturer juggling complex recipes across multiple production lines? Your manufacturing model – whether it’s batch processing, continuous production, or make-to-order – will significantly influence which solution fits best.

Understanding your Total Cost of Ownership (TCO) goes far beyond the sticker price. Yes, there’s the software licensing, but you’ll also need to budget for implementation services, staff training, ongoing support, potential customizations, and any hardware requirements. It’s like renovating a restaurant – the initial quote is just the beginning.

Vendor expertise in the food industry isn’t negotiable. You need a partner who understands that managing chocolate tempering is different from tracking automotive parts. Look for solutions designed specifically for food and beverage operations, not generic systems with food add-ons.

Consider your implementation resources honestly. Do you have the internal bandwidth – both in terms of time and technical expertise – to dedicate to this project? If your team is already stretched thin, partnering with experienced implementation specialists becomes crucial.

Change management often makes or breaks ERP implementations. The fanciest software in the world won’t help if your team isn’t ready to accept it. Successful implementations focus on people first, ensuring everyone understands not just how to use the new system, but why it will make their work better.

Finally, data migration deserves serious attention. Moving years of recipes, supplier information, and production data requires careful planning to ensure nothing gets lost in translation.

Cloud vs. On-Premise: What’s Right for You?

Choosing between cloud-based and on-premise deployment is like deciding between a food truck and a traditional restaurant – both can serve excellent food, but they suit different business models and preferences.

Cloud solutions offer remarkable flexibility and scalability. Your production manager can check inventory levels from home, your quality team can update inspection reports from the warehouse floor, and your executives can review real-time dashboards from anywhere. The lower upfront costs make cloud particularly attractive for growing businesses, since you’re subscribing to the service rather than making a massive capital investment.

Cloud providers handle the technical heavy lifting – updates, backups, security patches, and server maintenance – letting you focus on what you do best: creating amazing food products. NetSuite’s cloud-based platform exemplifies these advantages, offering food companies a unified, real-time view of their entire operation from a single system.

On-premise solutions appeal to businesses with specific security requirements or substantial existing IT infrastructure. You maintain complete control over your data and can customize the system extensively. However, this control comes with responsibility – you’ll handle maintenance, updates, and security internally, which requires dedicated IT resources.

Hybrid models are becoming increasingly popular, combining the best of both worlds. You might keep sensitive recipe formulations on-premise while leveraging cloud services for supplier collaboration and customer portals.

At Nuage, we’ve spent over 20 years helping companies steer these decisions. We don’t push one solution over another – instead, we work closely with you to understand your unique situation, security requirements, growth plans, and technical capabilities. Our goal is helping you find the right fit, whether that’s a cloud solution, on-premise deployment, or something in between.

The key is choosing a deployment model that supports your business goals, not the other way around. After all, your Food enterprise resource planning system should work for you, making your operations smoother and more profitable for years to come.

The Future of Food ERP: What’s Next on the Menu?

The food industry never stands still, and neither does Food enterprise resource planning. Just like your favorite restaurant constantly refines its menu, ERP technology keeps evolving to serve up better solutions for food businesses. What’s cooking in the future promises to make today’s impressive capabilities look like yesterday’s recipe book.

Artificial intelligence and machine learning are already changing how food companies operate, but we’re just getting started. Future ERP systems will use AI to deliver incredibly sophisticated predictive analytics for demand that go far beyond simple historical trends. Picture this: your ERP system notices unusual weather patterns and social media buzz around comfort foods, then automatically adjusts your production schedule and ingredient orders before you even realize demand is shifting. This level of intelligence will help food businesses reduce waste, optimize inventory, and stay ahead of market changes with unprecedented accuracy.

The Internet of Things (IoT) is creating a web of smart devices that will seamlessly connect with Food ERPs for real-time monitoring like never before. Smart sensors in your cold storage units, delivery trucks, and production equipment will constantly feed data back to your ERP system. This means you’ll know instantly if a refrigerated shipment gets too warm or if a mixer needs maintenance before it breaks down. This proactive approach will dramatically improve food safety while preventing costly equipment failures and product losses.

Sustainability isn’t just a buzzword anymore – it’s becoming a business requirement. Improved sustainability tracking will be built right into future Food ERP systems, helping companies monitor their environmental footprint with the same precision they track profits. Your ERP will track water usage, energy consumption, and carbon emissions across every step of your supply chain. This transparency will help you meet regulatory requirements while appealing to environmentally conscious consumers.

Blockchain technology promises the holy grail of food traceability – an unbreakable chain of custody from farm to fork. While current lot and batch tracking is already impressive, blockchain creates a tamper-proof, permanent record of every ingredient’s journey. If there’s ever a safety issue, you’ll be able to trace affected products instantly and with complete confidence. This ultimate traceability will revolutionize food safety and build unprecedented consumer trust.

The trend toward hyper-personalization is reshaping how food companies think about their products. Future Food ERPs will handle incredible complexity, managing thousands of recipe variations, custom packaging options, and individual dietary preferences at scale. Whether it’s gluten-free, keto-friendly, or personalized nutrition based on individual health data, your ERP will orchestrate these variations seamlessly.

These exciting developments highlight why choosing the right ERP partner matters so much. At Nuage, with our 20+ years of experience in digital change, we don’t just implement today’s solutions – we help you prepare for tomorrow’s opportunities. Our expertise with platforms like NetSuite ensures you’re building on a foundation that can grow and adapt as these technologies mature.

The future of Food enterprise resource planning isn’t just about better software – it’s about creating food systems that are smarter, safer, and more sustainable. And that future is closer than you might think.

Conclusion: Partnering for a Successful Digital Change

We’ve explored the transformative world of Food enterprise resource planning together, uncovering why it’s become the essential ingredient for thriving in today’s competitive food industry. From tackling the chaos of perishable inventory management to meeting stringent regulatory demands, a specialized Food ERP isn’t just nice to have—it’s absolutely critical.

The numbers tell a compelling story. Companies implementing these systems see a 15% boost in operational efficiency, slash inventory costs by 20%, and reduce waste by 10%. But beyond these impressive statistics lies something even more valuable: the peace of mind that comes from having complete control over your operations.

Think of a Food enterprise resource planning system as more than just software—it’s a strategic investment in your company’s future. It’s the foundation that supports sustainable growth and gives you a competitive edge in an industry that never sleeps. Whether you’re managing complex recipes, ensuring food safety compliance, or optimizing your supply chain, the right ERP system becomes your trusted partner in success.

But here’s the thing about any great recipe: success depends not just on quality ingredients, but on having an experienced chef who knows how to bring everything together perfectly. That’s exactly where we come in.

At Nuage, we’ve spent over 20 years helping companies steer their digital change journeys. We understand that implementing an ERP system is much more than installing software—it’s about fundamentally changing how your business operates. Our approach is refreshingly different: we focus on helping you determine the best solutions for your specific needs rather than pushing a one-size-fits-all product.

As NetSuite’s optimization partner, we bring deep expertise in NetSuite’s comprehensive platform to food businesses of all sizes. From our offices in Manhattan Beach, CA, and Ponte Vedra, FL, we’ve guided food companies across the globe through successful digital changes that deliver real, measurable results.

Your digital change journey doesn’t have to be overwhelming. With the right partner by your side, it becomes an exciting opportunity to revolutionize your operations, delight your customers, and build a more profitable future.

Ready to transform your food business with the power of integrated technology? Let’s start a conversation about how we can help you create the perfect blend of innovation and efficiency.

Explore our NetSuite solutions