Navigating Your Manufacturing ERP Journey

ERP implementation manufacturing industry involves integrating business and manufacturing processes into a single software platform for increased efficiency and visibility. For manufacturers considering this crucial step in digital change, here’s what you need to know:

Key Components of Manufacturing ERP Implementation:

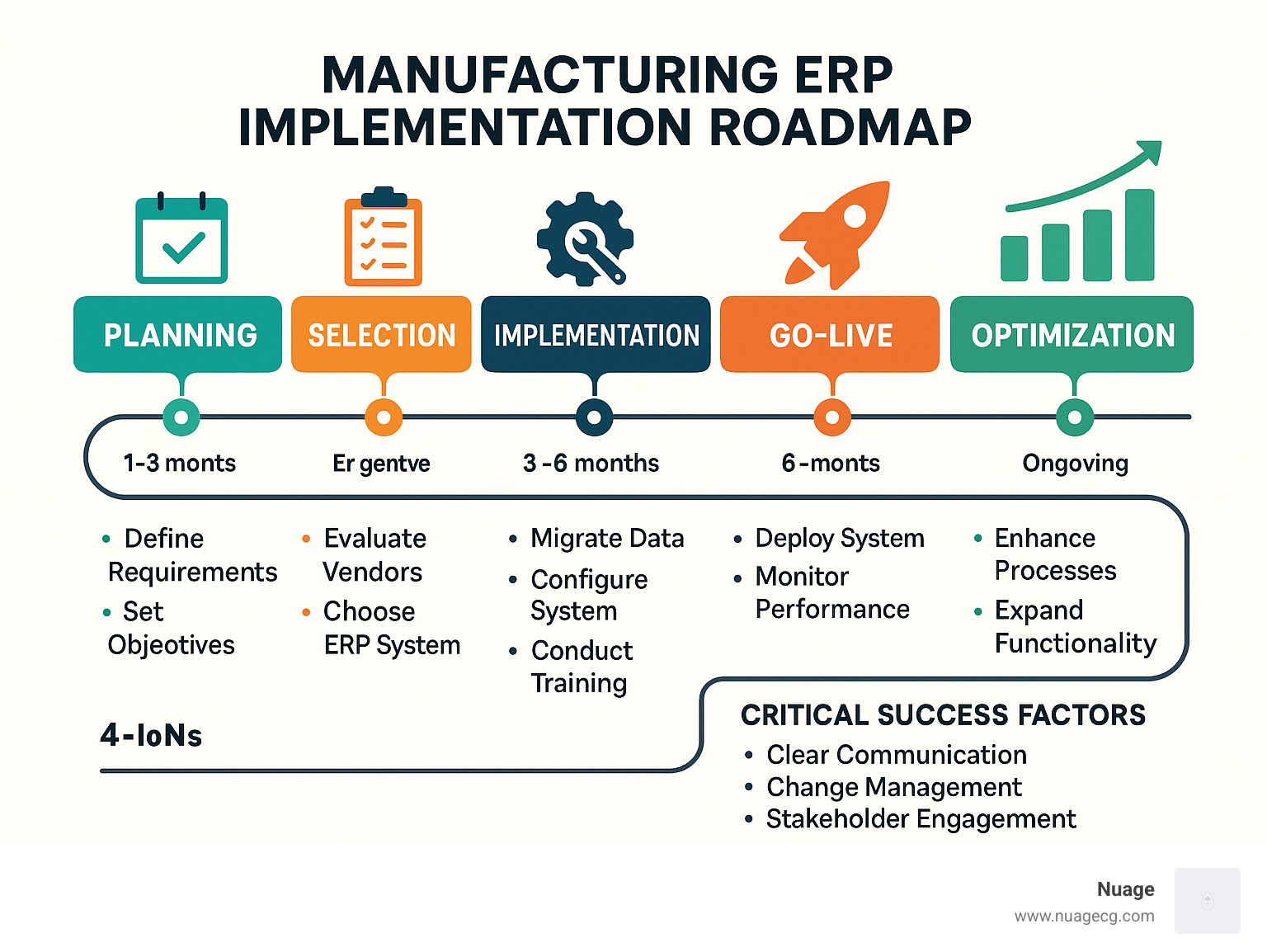

- Planning Phase: Business requirements, goals, timeline, and team assembly

- Selection Phase: Choosing the right ERP solution for your manufacturing type

- Implementation Phase: Data migration, configuration, testing, and training

- Go-Live Phase: System launch, monitoring, and immediate support

- Optimization Phase: Continuous improvement and feature expansion

In an industry where efficiency is constantly sought yet difficult to find, ERP implementation manufacturing industry projects can be true game-changers. The process of turning raw materials into finished goods involves countless moving parts—from procurement and inventory to production scheduling and quality control. Without a unified system, these functions often operate in silos, creating bottlenecks and preventing real-time decision making.

According to recent research, manufacturers who have implemented cloud ERP have experienced significant benefits:

- 56% reported reduced overall costs

- 46% cited improved IT security

- 46% experienced improved business agility and resiliency

The journey toward successful ERP implementation isn’t just about software installation. It’s a comprehensive business change that touches every department and workflow within your manufacturing operation. While the path may seem daunting, the potential rewards are substantial: streamlined operations, data-driven decisions, and a competitive edge in an increasingly digital marketplace.

I’m Louis Balla, CRO and partner at Nuage with over 15 years of experience in digital change and supply chain optimization, specializing in ERP implementation manufacturing industry projects for mid-market manufacturers. My expertise comes from overseeing countless implementations and integrating third-party applications to improve system capabilities.

ERP implementation manufacturing industry vocab to learn:

– ERP for batch manufacturing

– ERP for food manufacturing

– ERP systems for manufacturing

Why This Guide Matters

In today’s manufacturing world, having a single source of truth for your business data isn’t a luxury—it’s a necessity. Think about it: when everyone from your shop floor operators to your executive team can access the same accurate, real-time information, something magical happens. Decisions become clearer. Response times shrink. Confidence grows.

One of our manufacturing clients put it perfectly after their ERP implementation manufacturing industry project: “Before our ERP system, we were essentially flying blind. Different departments had different numbers, and reconciling them took days. Now, everyone works from the same data, and we can make decisions in minutes, not weeks.”

This guide matters because your ability to gain a competitive edge in manufacturing hinges on how well your systems support your actual business processes. With the right implementation approach, you’ll not only solve today’s problems but build in the scalability your business needs for tomorrow. We’ve seen how proper planning and execution can transform a manufacturing operation—and how cutting corners can lead to costly setbacks.

At Nuage, our 20+ years in the ERP business has taught us that successful implementations aren’t just about software. They’re about understanding the unique rhythm of your manufacturing processes and configuring systems that improve rather than disrupt that flow. Whether you’re looking to implement NetSuite for manufacturing or leverage the power of , this guide will help you steer the journey with confidence.

The manufacturing landscape is evolving rapidly. Those who can adapt their systems to match will thrive. Those who can’t may struggle to keep pace. Let’s make sure you’re in the first group.

ERP Implementation Manufacturing Industry: Foundations for Success

Enterprise Resource Planning (ERP) systems have come a long way since their humble beginnings as Materials Requirements Planning (MRP) systems back in the 1960s and 70s. What once simply tracked parts and materials has evolved into comprehensive platforms that bring your entire manufacturing operation together under one digital roof.

What Is ERP in Manufacturing?

At its heart, manufacturing ERP is the central nervous system of your production environment. Unlike one-size-fits-all business systems, a true manufacturing ERP understands the unique rhythm of your shop floor and speaks the language of production.

When we talk with manufacturing clients, we often describe it as the digital thread that connects everything from the moment you order raw materials to the second you ship finished products to your customers.

Production planning becomes streamlined with visual scheduling tools that help you maximize capacity. Inventory management transforms from a guessing game into a precise science. Quality control processes integrate directly with production, catching issues before they become expensive problems. And your financial reporting finally reflects the true costs and profitability of each product line.

I remember visiting a client six months after their implementation. The production manager smiled as he showed me his dashboard: “For twenty years, I started each morning with a stack of paper reports. Now I see everything I need in real time. I solved a potential material shortage before my first cup of coffee this morning!”

Learn more about ERP Systems for Manufacturing and how they differ from general business ERP solutions.

How ERP implementation manufacturing industry aligns with Industry 4.0

Modern ERP implementation manufacturing industry projects aren’t just about cleaning up old processes—they’re about building the foundation for your smart factory future. Today’s manufacturing ERP systems serve as the command center for Industry 4.0 initiatives by creating connections that weren’t possible before.

Think of your ERP as the brain that makes sense of all the data your smart factory generates. It takes inputs from IIoT devices on your shop floor—temperature sensors, production counters, quality inspection stations—and transforms that raw data into actionable intelligence.

The real magic happens when AI and advanced analytics enter the picture. One food manufacturer we worked with was able to reduce waste by 12% after their system started predicting quality issues based on subtle patterns in production data—patterns no human would have spotted.

According to a recent survey on cloud ERP benefits, manufacturers are embracing cloud-based ERP systems at accelerating rates. The numbers tell a compelling story: companies with cloud ERP respond faster to market changes and show greater operational agility than their competitors.

A production supervisor at a metal fabrication company put it perfectly: “Before our ERP implementation manufacturing industry project, we were always looking in the rearview mirror. Now we’re looking through the windshield, seeing what’s coming and adjusting in real-time.”

For manufacturers ready to explore how ERP can transform their operations, both and NetSuite offer robust platforms specifically designed for manufacturing environments. At Nuage, we help you steer these options to find the perfect fit for your unique production requirements.

Key Benefits of ERP for Manufacturing Companies

When manufacturers implement an ERP system, they’re not just installing new software—they’re changing how their entire business operates. The benefits touch every corner of the organization, from the shop floor to the boardroom.

Operational Efficiency Gains

ERP implementation manufacturing industry projects create remarkable improvements in day-to-day operations. The automation of routine tasks means your team spends less time on paperwork and more time on value-adding activities. One of our clients put it perfectly: “After implementing our ERP system, we reduced order processing time by 65% and increased throughput by 28% without adding staff.”

Modern manufacturing ERP systems eliminate redundant steps and bottlenecks through streamlined workflows. They support the shift to paperless operations by digitizing everything from work instructions to quality records. For companies embracing lean manufacturing principles, ERP provides the visibility needed to identify and reduce waste throughout production processes.

The system becomes your early warning system—automatically triggering replenishment and highlighting production bottlenecks before they impact your delivery dates. This proactive approach transforms how teams work and collaborate.

Financial & Strategic Advantages

The financial impacts of a well-implemented ERP system can be transformative. Improved cash flow management gives you better visibility into receivables and payables, helping you make smarter decisions about when to spend and when to save.

“Our ERP implementation transformed our financial operations,” shared a CFO from one of our mid-sized manufacturing clients. “We reduced month-end close from 15 days to 3, improved inventory accuracy from 82% to 99.5%, and gained the ability to analyze profitability by product, customer, and production line in real-time.”

With real-time financial KPIs at your fingertips, you can spot trends and address issues before they become problems. Your forecasting becomes more accurate, leading to better sales and production planning. Perhaps most importantly, a proper ERP implementation creates scalability—supporting your growth without requiring proportional increases in overhead and administrative staff.

Want to learn more about how digital change can reshape your manufacturing business? Check out our detailed guide on Digital Change for Manufacturing.

Supply Chain & Production Planning Boosts

The supply chain improvements from ERP implementation manufacturing industry projects are often where manufacturers see the most dramatic results. Better demand forecasting means you can reduce safety stock while still meeting customer needs. Procurement processes become streamlined with automated purchasing and vendor management.

Production scheduling—often a headache for manufacturers—becomes a strategic advantage. Advanced scheduling capabilities optimize production sequences and resource utilization, while supplier performance tracking gives you objective data on quality, delivery times, and pricing.

A supply chain director we worked with explained it this way: “Before implementing our ERP system, we struggled with constant expediting and firefighting. Now, our system forecasts demand, suggests optimal order quantities, and helps us evaluate supplier performance objectively. Our on-time delivery improved from 76% to 94% within six months.”

With a properly implemented manufacturing ERP system, you’ll find yourself making decisions based on data rather than hunches, predicting problems before they occur, and spending your time on strategic improvements rather than fighting daily fires.

Step-by-Step Roadmap: ERP Implementation Manufacturing Industry Projects

Successful ERP implementation manufacturing industry projects don’t happen by accident. At Nuage, we’ve refined our approach over 20+ years of guiding manufacturers through digital changes. Think of our roadmap as your GPS for the ERP journey—helping you steer each turn with confidence.

Milestone Checklist for ERP implementation manufacturing industry

Every successful implementation journey has signposts that tell you you’re on the right track. These critical checkpoints help keep your project from veering off course:

Your Project Charter serves as your North Star—defining what you’re trying to accomplish, how you’ll measure success, and the boundaries of your project. It’s the document everyone can point to when questions arise about project scope.

A thorough Risk Register is like insurance for your implementation. One manufacturing client told us, “Identifying potential pitfalls early meant we could prepare for them rather than be surprised by them.”

Selecting and training Super-Users in each department creates internal champions who speak both the language of your business and the language of your new ERP. These folks become the bridge between technical capabilities and real-world needs.

User Acceptance Testing isn’t just a technical exercise—it’s where your team confirms that the system will actually solve your business problems. As one production manager put it, “UAT was where the system stopped being ‘theirs’ and started becoming ‘ours.’”

The remaining milestones—Data Migration Validation, Go-Live Readiness Assessment, and Post-Implementation Review—create a safety net ensuring nothing critical falls through the cracks as you transition to your new system.

People, Process, Data, System Framework

At Nuage, we’ve learned that successful ERP implementation manufacturing industry projects require more than just good software. Our framework addresses all four critical dimensions:

The People dimension focuses on bringing your team along on the journey. Without proper change management, even the best system will struggle to gain traction. We help you communicate the “why” behind the change, develop new skills through targeted training, and clearly define who’s responsible for what.

The Process dimension is about how work gets done. We start by mapping your current processes, then design future-state workflows that leverage your new system’s capabilities. The gap between these states becomes your change roadmap.

Your Data is the lifeblood of your new system. We establish governance rules, clean existing information, and ensure your master data (products, customers, suppliers, etc.) is accurate before migration. As one client noted, “The time we spent cleaning data upfront saved us countless headaches after go-live.”

Finally, the System dimension covers configuration, integration with other platforms, necessary customizations, and thorough testing. We believe in configuring rather than customizing wherever possible—keeping your system easier to upgrade and maintain.

Testing, Cut-Over & Hyper-Care

The final stages of your implementation are where theory meets reality. A manufacturing COO once told us, “The difference between a smooth go-live and a disaster often comes down to how thoroughly you test and how carefully you plan the transition.”

Effective Testing is like a dress rehearsal for your go-live. We start with unit testing individual components, then progressively expand to integration testing, performance testing under load, and user acceptance testing with real-world scenarios. The culmination is a full dress rehearsal that simulates the actual go-live process.

The Cut-Over phase is the actual transition to your new system. We help you execute final data migration, activate your new ERP, decommission legacy systems, and communicate changes to all stakeholders. This phase requires precise coordination—like a well-choreographed dance where everyone needs to know their steps.

Hyper-Care provides intensive support during those crucial first weeks of using your new system. We monitor performance, track and resolve issues, and measure user adoption. One client described this phase as “having expert coaches on the sidelines during our first big game.”

For more detailed guidance on implementation best practices that apply to any ERP system, check out our NetSuite Implementation Guide.

Choosing Deployment Models & Selecting the Right Solution

Selecting the right deployment model and solution is perhaps the most consequential decision you’ll make in your ERP implementation manufacturing industry journey. It’s like choosing the foundation for your new house—everything else will be built upon it.

Evaluating Manufacturing-Focused ERP Vendors

When we sit down with manufacturing clients at Nuage, we often hear stories of past software purchases that sounded perfect in the sales pitch but fell short in reality. That’s why we recommend focusing on these practical factors:

Industry Fit matters tremendously—a vendor with deep manufacturing expertise will understand your unique challenges around production scheduling, inventory management, and quality control. They’ll speak your language and anticipate your needs.

Your ERP should grow with you, so examine the vendor’s Product Roadmap to ensure their future development aligns with your strategic direction. Are they investing in the manufacturing capabilities you’ll need tomorrow?

The Support Model can make or break your experience after go-live. Ask detailed questions about response times, escalation procedures, and whether support staff understand manufacturing operations.

Nothing speaks louder than the experiences of others. Request Customer References specifically from manufacturers similar to yours in size, complexity, and sub-industry.

Finally, get clarity on Service Level Agreements—what guarantees do they offer for system uptime, performance, and support responsiveness?

“We interviewed three vendors who all claimed manufacturing expertise,” recalled a COO at a discrete manufacturer. “But only one could demonstrate a deep understanding of our specific production challenges and had reference customers in our industry. That made our decision much easier.”

Aligning With & NetSuite Ecosystems

At Nuage, we’ve chosen to partner with two exceptional platforms that consistently deliver results for our manufacturing clients: and NetSuite.

has earned its reputation as a manufacturing powerhouse. Its comprehensive capabilities span the entire production lifecycle, from design to delivery. We’ve seen clients particularly value its robust asset management functionality, which helps maximize equipment uptime and efficiency. The integrated project management and field service modules make it ideal for manufacturers who also install or service what they build. Most impressive is how IFS tailors functionality to specific manufacturing types—whether you’re running discrete, process, or mixed-mode operations.

NetSuite takes a different but equally powerful approach. As a true cloud-native platform, it offers remarkable speed to value with its rapid implementation methodology. Our manufacturing clients love the Advanced Manufacturing module, which provides sophisticated capabilities without overwhelming complexity. The SuiteCloud platform lets you extend functionality as your needs evolve, while the financial management capabilities give unprecedented visibility into costs and profitability across your operation.

Both platforms have their sweet spots. For example, we recently helped a mid-sized food manufacturer implement NetSuite because its multi-entity capabilities perfectly matched their structure with multiple production facilities. Meanwhile, a heavy equipment manufacturer chose for its superior asset management and service capabilities.

The key is finding the right fit for your specific needs, which is why at Nuage, we start with your requirements rather than pushing a particular solution. Our approach is consultative—we help you determine which platform aligns best with your manufacturing type, size, and strategic priorities.

For deeper insights into how NetSuite can transform manufacturing operations, explore our guide to NetSuite ERP for Manufacturing. If you’re curious about ’s unique strengths for manufacturers, visit our services page for detailed information.

Overcoming Challenges & Measuring ROI

Let’s face it – no ERP implementation manufacturing industry project goes perfectly smooth. Even the best-planned implementations hit bumps in the road. What separates successful projects from disappointing ones isn’t avoiding challenges altogether (that’s impossible), but how you anticipate and respond to them.

Risk Mitigation Tactics

After guiding hundreds of manufacturers through their ERP journeys, we’ve developed practical approaches to keeping projects on track:

Executive sponsorship isn’t just a box to check – it’s the lifeline of your implementation. When department heads push back on process changes (and they will), having your CEO actively champion the project makes all the difference.

As one project sponsor told us: “When our shipping department resisted the new workflows, our CEO personally attended their training session and explained why these changes were crucial for our five-year growth plan. Resistance melted away almost immediately.”

Phased rollouts give your team breathing room to adapt. Rather than the “big bang” approach, consider implementing core modules first, then expanding functionality after users gain confidence. This creates early wins that build momentum.

Creating a sandbox environment provides a safe playground where your team can practice without fear of breaking anything. We’ve found users who spend time experimenting in the sandbox require significantly less support after go-live.

Partnering with experienced consultants brings battle-tested wisdom to your project. At Nuage, we don’t just implement software – we transfer knowledge so your team becomes self-sufficient. As one manufacturing client put it: “Having someone who’d seen our exact challenges before saved us months of trial and error.”

Proving Success & Continuous Optimization

The real work begins after go-live. Measuring ROI and continuously improving your system ensures lasting value from your investment.

Smart manufacturers track specific metrics that demonstrate tangible improvements. Overall Equipment Effectiveness (OEE) often shows the most dramatic gains, as one metal fabricator finded when their OEE jumped from 67% to 83% within six months of implementation.

Inventory turns typically improve as visibility increases, freeing up working capital. One food manufacturer reduced inventory by 22% while maintaining better service levels after implementing their ERP system.

Production cycle times almost always shrink when manual handoffs are eliminated. A plastics manufacturer shaved 40% off their average production time by automating their scheduling and work order processes.

Cost variance reporting becomes dramatically more accurate and timely. Rather than finding problems at month-end, manufacturers can address variances daily, preventing small issues from becoming costly problems.

“The dashboard we built shows our on-time delivery performance in real-time,” shared a production manager. “Having that number visible to everyone created healthy competition between shifts to improve it. We went from 76% to 94% on-time in just four months.”

Continuous improvement doesn’t happen automatically. Smart manufacturers schedule regular system health checks, collect user feedback systematically, and create internal champions who drive adoption of new features. The most successful clients we work with establish “ERP excellence teams” that meet monthly to identify opportunities for optimization.

“We treated go-live as the starting line, not the finish line,” explained a continuous improvement manager. “Our monthly optimization meetings have delivered more value than the initial implementation because we’re constantly fine-tuning the system to match our evolving business.”

For more strategies on maximizing your manufacturing ERP investment, visit our blog on ERP Solutions for Manufacturing.

Frequently Asked Questions about ERP Implementation in Manufacturing

When is the right time to start an ERP project?

If you’re wondering when to kick off your ERP implementation manufacturing industry project, look for these telltale signs that your business is ready:

Your team spends more time shuffling papers than making products. When manual processes are slowing you down and causing headaches, it’s time for a change. One manufacturing client told us, “We knew it was time when our production manager started carrying three different clipboards to track what should have been in one system.”

Do your sales team, finance department, and shop floor all report different inventory numbers? These data discrepancies aren’t just annoying – they’re costing you money and customer trust.

Limited visibility across departments is another red flag. If you can’t quickly answer questions like “Where are we on that order?” or “What’s our current capacity?”, an ERP system could transform your operation.

Growth challenges often trigger ERP projects too. As one manufacturing executive confided: “We waited too long to implement our ERP system. Looking back, we should have started when we first noticed our spreadsheets couldn’t keep up with our growth. The warning signs were there a year before we acted.”

The best time to plant a tree was twenty years ago. The second best time is now. The same wisdom applies to ERP implementation manufacturing industry projects.

How long does a typical manufacturing ERP rollout take?

“How long will this take?” is usually the second question we hear after “How much will this cost?” The honest answer is: it depends on several factors.

For small manufacturers with straightforward processes, you might complete an implementation in 3-6 months. Mid-sized operations typically need 6-12 months, while larger enterprises with complex requirements often require 12+ months.

Your approach matters too. A phased implementation (tackling finance first, then operations, etc.) spreads the work over a longer period but can reduce risk. An all-at-once approach is faster but more intensive.

The amount of customization dramatically impacts timelines. Sticking with standard configurations speeds things up, while extensive customization extends the project.

Data complexity is often underestimated. As an IT director shared with us: “Our implementation took 9 months from kickoff to go-live. We originally planned for 6 months, but underestimated the time needed for data cleansing and user training. The extra time was well worth it for a smooth transition.”

Your team’s readiness for change and availability to work on the project can either accelerate or delay implementation. Having dedicated resources makes a world of difference.

A successful implementation that takes a bit longer is infinitely better than a rushed implementation that fails to deliver value.

What KPIs should we track post-go-live?

After going live with your ERP implementation manufacturing industry project, measuring success is crucial. Here’s what to track:

On the shop floor, focus on production throughput, setup times, first-pass yield, machine utilization, and labor efficiency. These operational metrics will show you how your new system is improving daily production.

For the finance team, keep an eye on inventory carrying costs, cost of goods sold, gross margin by product, days sales outstanding, and your cash conversion cycle. A good ERP system should positively impact all these financial indicators.

Don’t forget your customers! Track on-time delivery, perfect order fulfillment, order cycle time, customer satisfaction scores, and service response time. After all, happy customers are the ultimate measure of success.

“We created a balanced scorecard of KPIs that we review weekly,” explained a manufacturing operations director who worked with our team. “This keeps us focused on the metrics that matter most to our business and helps us quantify the return on our ERP investment.”

I recommend creating dashboards in your new system that make these KPIs visible to everyone who needs them. When people can see progress, they’re more likely to accept the new system and processes.

At Nuage, we help our clients set up these measurement frameworks as part of implementation. By establishing baselines before go-live, you can clearly demonstrate the value your or NetSuite implementation brings to the business.

Conclusion & Next Steps

The journey of ERP implementation manufacturing industry projects is much like manufacturing itself—changing raw potential into something of greater value. By following the roadmap and best practices we’ve explored, you’re not just installing software; you’re building a foundation for sustainable growth and competitive advantage.

Future-proofing your manufacturing operations isn’t optional in today’s rapidly evolving marketplace. The manufacturers who thrive will be those who accept digital change and leverage their ERP system as a platform for continuous improvement and innovation. When your entire organization operates from a single source of truth, decisions become faster, more accurate, and more confident.

As one of our clients, a manufacturing operations director, recently told us: “Our ERP implementation wasn’t the end of our digital journey—it was just the beginning. Now that we have reliable data, we’re finding opportunities for improvement we never knew existed.”

At Nuage, we’ve spent over two decades guiding manufacturers through successful ERP implementations. Our approach is different—we focus on understanding your unique challenges rather than pushing a one-size-fits-all solution. We believe the right technology should adapt to your business, not the other way around.

Whether you’re just beginning to explore ERP options or looking to optimize an existing system, our team can help you steer the complexities with confidence. With offices in Manhattan Beach, CA and Ponte Vedra, FL, we partner with manufacturers nationwide to deliver implementations that drive real business value.

The true measure of ERP implementation manufacturing industry success isn’t going live on time and on budget—though those are important milestones. Real success comes from changing how your business operates, empowering your people with better information, and ultimately delivering greater value to your customers.

Ready to take the next step in your ERP journey? Learn more about our services or explore how NetSuite can transform your manufacturing operations. Contact us for a consultation custom specifically to your manufacturing needs—because your success is our success.