The Manufacturing Tech Gap: Why You Need ERP Today

ERP for industrial manufacturing is a specialized enterprise resource planning system that integrates all key manufacturing operations—from production planning and shop floor control to inventory management and supply chain optimization—into a single unified platform.

Quick Answer: Best ERP Systems for Industrial Manufacturing

- Cloud-based options: NetSuite Manufacturing Edition,

- On-premise solutions: , NetSuite Manufacturing Edition

- For SMBs: NetSuite Manufacturing Edition,

Did you know only 39% of manufacturing workers say their technology is very modern? This striking statistic reveals the digital change gap plaguing industrial manufacturers today. While your competitors invest in cloud, AI and data analytics to gain competitive advantages, outdated systems leave many manufacturers struggling with disconnected data silos, manual spreadsheets, and productivity bottlenecks.

The consequences? Lost revenue, inefficient operations, and frustrated employees.

Modern manufacturing ERP systems address these challenges by:

- Unifying data across departments

- Automating manual processes

- Providing real-time visibility into operations

- Enabling data-driven decisions with analytics

- Supporting compliance requirements

- Improving supply chain resilience

Manufacturers who implement cloud ERP experience tangible benefits: 56% report reduced overall costs, 46% improved IT security, and 46% improved business agility and resilience.

I’m Louis Balla, CRO and partner at Nuage, with over 15 years of experience in digital change and ERP for industrial manufacturing implementations. I specialize in helping manufacturing businesses streamline operations through strategic ERP deployment and integration.

Industrial Manufacturing 101: How ERP Powers the Shop Floor

Remember when manufacturing plants ran on clipboards and paper tickets? Those days are rapidly disappearing as modern industrial manufacturing accepts digital change. Today’s smart factories need systems that connect every aspect of production into a unified whole.

ERP for industrial manufacturing serves as the backbone of this change—the central nervous system that coordinates your entire operation. Unlike traditional MRP (Material Requirements Planning) systems that narrowly focus on production planning and inventory, modern ERP solutions encompass your whole business journey from initial customer quote to final payment, procurement to production, and shop floor activities to executive decision-making.

The industrial landscape has evolved dramatically with Industry 4.0 bringing IIoT sensors, real-time data collection, and unprecedented visibility into operations. Modern manufacturers can’t compete effectively without these technological advantages.

Research published in The Register reveals that ERP implementation failures can cost companies millions—sometimes billions—of dollars. The most common pitfalls? Poor requirements gathering, inadequate change management, and selecting solutions that don’t address industry-specific needs.

Why “erp for industrial manufacturing” Is Mission-Critical

Industrial manufacturers face unique challenges that generic business software simply can’t handle:

Manufacturing complexity demands specialized solutions—whether you’re running discrete assembly operations, process manufacturing with continuous flows, or mixed-mode production combining both approaches. Your operations require purpose-built functionality.

Regulatory compliance requirements grow more stringent every year, with traceability, documentation, and reporting becoming increasingly critical. Without robust systems, compliance becomes a costly nightmare.

A properly implemented ERP for industrial manufacturing transforms operations through:

Centralized database that eliminates information silos and creates a single source of truth across all departments. When your production manager, inventory team, and finance department all work from the same real-time data, coordination improves dramatically.

Automation of routine tasks from purchase order creation to production scheduling frees your valuable human resources for more strategic work. This isn’t about replacing people—it’s about letting them focus on what humans do best.

Predictive analytics leveraging AI and machine learning helps you anticipate maintenance needs, optimize inventory levels, and forecast demand with greater accuracy than ever before.

Key Benefits by Manufacturing Type

Different production models require different ERP capabilities. Here’s how ERP for industrial manufacturing benefits various approaches:

Discrete Manufacturing operations benefit from robust BOM management, assembly line scheduling, serial number tracking, and engineering change management. Quality control at the component level ensures consistent products while minimizing waste.

Batch Manufacturing thrives with recipe and formula management, batch scheduling, lot traceability, and yield analysis. Quality testing by batch helps maintain consistency across production runs.

Process Manufacturing requires continuous flow monitoring, tank and vessel management, ingredient traceability, and regulatory compliance tools. By-product and co-product tracking helps maximize resource utilization.

Engineer-to-Order operations need project management integration, custom BOM creation, design integration, and cost tracking by project. Change order management ensures profitability despite evolving specifications.

Make-to-Stock manufacturers rely on demand forecasting, inventory optimization, production planning, and distribution capabilities to keep finished goods moving efficiently to customers.

At Nuage, we’ve spent over 20 years helping manufacturers select and implement the right ERP solutions for their specific needs. Our expertise with platforms like NetSuite Manufacturing Edition and allows us to recommend solutions based on your actual requirements—not on what we’re trying to sell.

Feature Slam-Dunk: Must-Have Modules in an ERP for Industrial Manufacturing

Shopping for an ERP for industrial manufacturing can feel like standing in front of a buffet with too many choices. Which features are essential, and which are just nice-to-haves? After helping dozens of manufacturers transform their operations over the past 20 years, we’ve identified the non-negotiable modules that truly move the needle from chaos to clarity.

Top 10 Feature Checklist for “erp for industrial manufacturing”

Think of your manufacturing ERP as the central nervous system of your operation. To function properly, it needs these critical components:

BOM Management sits at the heart of any manufacturing system. You need the ability to create and version multi-level bills of materials that track your product through its entire lifecycle – from “as designed” to “as built” to “as maintained.” This single source of truth eliminates costly errors and confusion.

Production Planning & Scheduling is where the rubber meets the road. The best systems balance demand, capacity, and materials with sophisticated algorithms that create optimal production schedules. When you can visualize your entire production flow on intuitive Gantt charts, bottlenecks become immediately apparent.

Shop Floor Control gives you that priceless real-time visibility. When operators can report production status, labor time, and machine utilization from mobile devices right on the shop floor, you eliminate the data lag that causes so many headaches.

Inventory Management might seem basic, but it’s anything but. Beyond simple counting, you need multiple valuation methods, ABC analysis, cycle counting capabilities, and min/max planning that works across different units of measure and locations.

Quality Management integration saves you from the paperwork nightmare of separate quality systems. Look for built-in inspection planning, statistical process control, and corrective action workflows that maintain your standards without slowing production.

Supply Chain Management extends your system beyond your four walls. Comprehensive vendor management, purchase order processing, and supplier performance tracking become even more powerful when suppliers can collaborate through dedicated portals.

Product Lifecycle Management bridges the gap between engineering and production. When your ERP integrates with engineering systems, you maintain control over product data and engineering changes throughout the entire product journey.

Maintenance Management keeps your assets running at peak performance. Smart scheduling of preventive maintenance, streamlined work orders, and equipment history tracking can dramatically reduce costly downtime.

Financial Management custom for manufacturing makes all the difference. Standard costing, actual costing, job costing, and variance analysis give you the financial visibility that generic accounting packages simply can’t provide.

Analytics & Reporting transform raw data into actionable insights. Real-time dashboards and customizable KPI tracking help you spot trends, identify problems, and make better decisions faster.

At Nuage, we’ve implemented these critical features for manufacturers through our partnerships with NetSuite and . Each platform has unique strengths, and we pride ourselves on matching the right solution to your specific manufacturing model.

Advanced Tech That Sets Leaders Apart

While the core features form your foundation, certain cutting-edge technologies are separating manufacturing leaders from followers:

Digital Twins create virtual replicas of your physical assets and processes. This technology lets you simulate changes and optimizations without disrupting actual production – a game-changer for continuous improvement initiatives.

Predictive Maintenance uses AI to analyze equipment performance data and predict failures before they happen. One of our clients reduced unplanned downtime by 27% in the first year after implementation, saving hundreds of thousands in lost production time.

Embedded Analytics put business intelligence directly into your workflow. Rather than generating reports that sit unread in inboxes, these tools present insights exactly when and where decisions are being made.

IIoT Gateways connect your machines directly to your ERP. When production equipment automatically reports status, cycle times, and quality measurements, you eliminate manual data entry and gain unprecedented visibility.

Augmented Reality applications are changing worker productivity. Imagine maintenance technicians seeing repair instructions overlaid directly on equipment, or quality inspectors with digital checklists that automatically record findings.

excels in IoT connectivity, helping our manufacturing clients achieve remarkable improvements in Overall Equipment Effectiveness. Meanwhile, NetSuite Manufacturing Edition offers powerful predictive analytics that optimize inventory levels and production schedules based on historical patterns and market trends.

The right ERP for industrial manufacturing doesn’t just digitize your current processes – it transforms how you operate. And the difference between merely implementing software and achieving true digital change often comes down to having the right partner to guide your journey.

Deployment Decisions & Solution Shortlist

One of the most critical decisions when selecting an ERP for industrial manufacturing is the deployment model. Each approach offers distinct advantages and considerations that must be aligned with your business objectives, IT capabilities, and budget constraints.

| Deployment Model | Pros | Cons | Best For |

|---|---|---|---|

| Cloud SaaS | Lower upfront cost, rapid implementation, automatic updates, reduced IT burden | Less customization flexibility, ongoing subscription costs, potential internet dependency | Companies seeking rapid deployment, limited IT resources, and predictable operating expenses |

| On-Premise | Maximum control, deep customization, one-time licensing, no internet dependency | Higher upfront cost, IT maintenance burden, manual updates, hardware requirements | Organizations with strict data control requirements, extensive customization needs, and strong IT resources |

| Hybrid | Flexibility to keep critical systems on-premise while leveraging cloud for others, staged migration path | Complexity of managing multiple environments, potential integration challenges | Companies transitioning from legacy systems or with mixed requirements for control and accessibility |

Cloud ERP for Industrial Manufacturing: Pros, Cons, ROI

Cloud-based ERP for industrial manufacturing has gained significant traction in recent years, with good reason. According to a Rootstock survey, manufacturers who implemented cloud ERP experienced:

- 56% reduced overall costs

- 46% improved IT security

- 46% improved business agility and resilience

The cloud model offers several compelling advantages:

Rapid Updates: Cloud ERP vendors typically release updates multiple times per year, ensuring you always have access to the latest features and security patches.

Lower IT Burden: The vendor handles infrastructure, backups, security, and maintenance, allowing your IT team to focus on strategic initiatives rather than system upkeep.

Accessibility: Cloud systems can be accessed from anywhere with an internet connection, enabling remote work, multi-site operations, and mobile access.

Scalability: Cloud platforms can easily scale up or down based on your needs, making them ideal for growing businesses or those with seasonal fluctuations.

However, cloud ERP isn’t without challenges:

Internet Dependency: Production could be impacted during internet outages (though most modern systems offer offline capabilities).

Subscription Model: While reducing upfront costs, the ongoing subscription fees can exceed one-time licensing costs over many years.

Customization Limitations: Some cloud platforms restrict deep customizations to maintain upgrade compatibility.

In our experience at Nuage, NetSuite offers one of the most robust cloud-based ERP for industrial manufacturing solutions, with a proven track record of success across various manufacturing sectors. Industry studies have shown that organizations using modern cloud ERP can achieve remarkable ROI and significant net present value.

On-Premise & Hybrid: When Control Trumps Convenience

Despite the cloud trend, on-premise and hybrid deployments remain viable—and sometimes preferable—options for certain industrial manufacturers.

On-premise ERP may be the right choice when:

- Data residency requirements mandate keeping sensitive information within your physical facilities

- Network latency would impact real-time shop floor operations

- Deep customization is needed to support unique manufacturing processes

- Long-term cost analysis favors one-time licensing over ongoing subscriptions

- Existing IT infrastructure can be leveraged to reduce implementation costs

Hybrid ERP offers a middle ground, allowing you to:

- Keep critical or sensitive functions on-premise while moving others to the cloud

- Gradually transition from legacy systems to modern platforms

- Maintain control over manufacturing execution while leveraging cloud for planning and analytics

- Balance capital expenses with operating expenses

excels in both on-premise and hybrid deployments, offering the same functionality regardless of deployment model. This flexibility has made it a popular choice among our manufacturing clients who require a custom approach to their ERP strategy.

Winning Playbook: Evaluating, Implementing & Optimizing Your ERP

Let’s face it – selecting and implementing the right ERP for industrial manufacturing feels a bit like planning a wedding and building a house simultaneously. It’s complex, expensive, and if done wrong, you’ll be reminded of the mistake for years to come! At Nuage, we’ve refined this process over our 20+ years in the industry, developing a proven approach that maximizes success while keeping your stress levels in check.

Step 1: Requirements Definition & Vendor Selection

Start by mapping your current reality – the good, the bad, and the “how have we survived doing it this way for so long?” Document your processes, pain points, and what your ideal future state looks like. Create a detailed requirements matrix covering everything from production planning to finance.

Think of this matrix as your manufacturing ERP shopping list. It helps you evaluate vendors objectively by assigning weights to features based on importance. Is real-time shop floor visibility a must-have while advanced forecasting is just nice-to-have? Your matrix should reflect these priorities.

Don’t just look at features, though. Consider the vendor’s manufacturing expertise, implementation approach, and support model. Ask for references specifically from your industry. And remember – the sticker price is just the beginning of your total cost of ownership calculation.

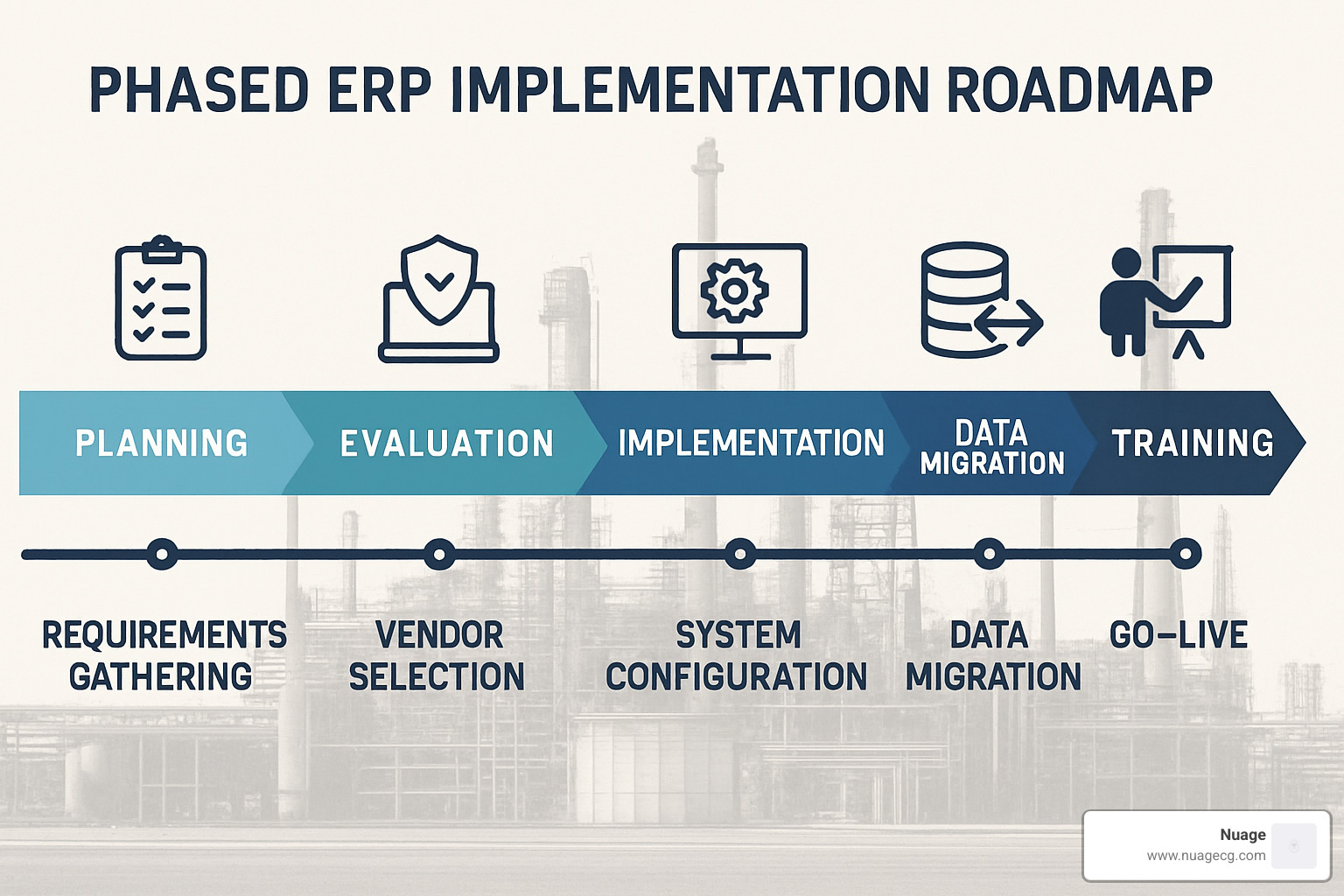

Step 2: Implementation Planning & Execution

With your ERP for industrial manufacturing solution selected, it’s time to build your implementation roadmap. This isn’t just an IT project – it’s a business change that requires thoughtful planning across multiple dimensions.

Project governance establishes who makes decisions and how they’re made. Change management ensures your team accepts the new system rather than working around it. Data migration is often underestimated – start cleaning your data early (you probably have more “junk” in your current systems than you realize).

Consider a phased approach to reduce risk. Many of our clients start with core financials and inventory, then add production planning, and finally implement shop floor control. This approach creates early wins and allows your team to adapt gradually rather than facing a massive overnight change.

Step 3: Continuous Improvement & Optimization

The go-live celebration is just the beginning of your ERP journey. The most successful manufacturers view their ERP for industrial manufacturing as a living system that evolves with their business.

Set up KPI dashboards to measure the impact on your operations. Are you seeing the inventory reductions you expected? Has on-time delivery improved? These metrics tell you where you’re succeeding and where further optimization is needed.

Create regular feedback loops with your users. The people using the system daily often have the best suggestions for improvements. Schedule quarterly system reviews to ensure your ERP continues to meet your evolving business needs and to plan for upcoming upgrades.

Avoiding Common Pitfalls in “erp for industrial manufacturing”

Through countless implementations, we’ve seen smart companies stumble in predictable ways. Let me share some hard-earned wisdom to help you avoid these common traps:

Scope creep is the silent budget-killer. Start with a clearly defined scope and establish a formal process for evaluating new requirements that emerge during implementation.

Bad data creates bad decisions, no matter how sophisticated your system. Dedicate resources to cleansing and validating your data before migration.

Resistance to change can undermine even the best technical implementation. Manufacturing environments often have long-tenured employees who’ve mastered current processes. Show them how the new system makes their jobs easier, not just how it helps the company.

Vendor lock-in limits your future flexibility. Look for open APIs, standard data models, and transparent exit strategies before signing on the dotted line.

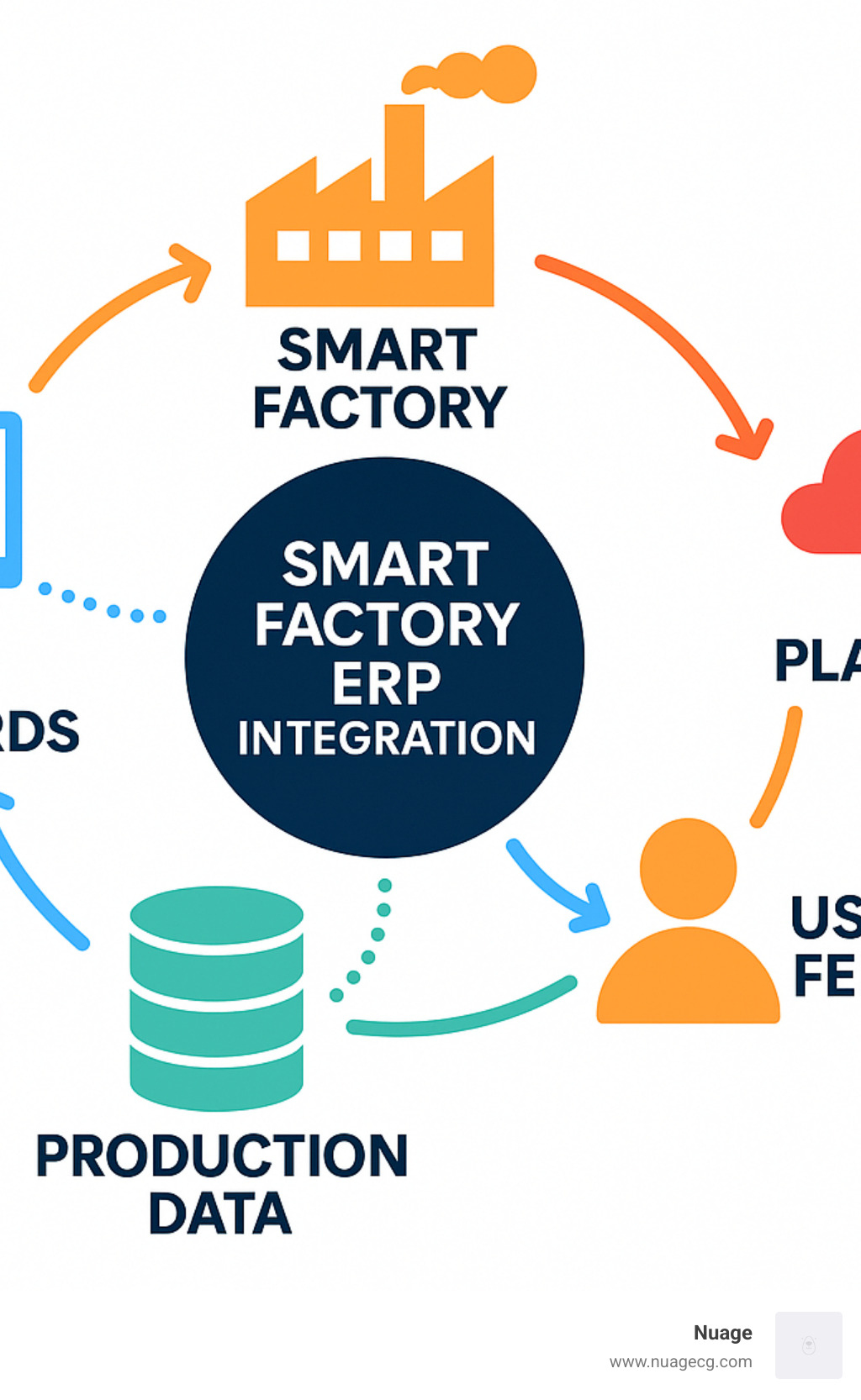

Future-Proof With Industry 4.0 & Smart-Factory Integration

The manufacturing landscape is evolving rapidly. Your ERP for industrial manufacturing should serve as the foundation for your Industry 4.0 journey, not a roadblock.

Look for systems that maintain a digital thread connecting design, production, quality, and service throughout the product lifecycle. Evaluate the vendor’s capabilities for IIoT integration and their roadmap for incorporating AI and machine learning into planning, scheduling, and maintenance processes.

As factories become smarter, your ERP will need to interact with increasingly autonomous systems, from robotics to automated guided vehicles. And with growing focus on environmental impact, ensure your system can track sustainability metrics like energy usage, waste, and carbon footprint.

Both NetSuite and have made significant investments in these future-focused capabilities. At Nuage, we help our clients leverage these technologies to not just keep pace with Industry 4.0, but to lead their industries in digital change.

Our approach combines technical expertise with practical manufacturing knowledge. We’ve guided companies through digital change for over two decades, helping them avoid costly mistakes while maximizing the return on their ERP investment. The key is viewing implementation not as a one-time project but as the beginning of a continuous improvement journey.

Frequently Asked Questions About ERP for Industrial Manufacturing

What’s the expected ROI and timeline?

When manufacturers ask me about the return on investment for erp for industrial manufacturing, I always emphasize that results vary based on your unique situation. That said, the numbers tell a compelling story:

Industry studies have found that modern ERP customers can achieve impressive ROI with significant net present value. Manufacturers using leading solutions have optimized inventory much faster and increased first-time fixes substantially in just 60 days. In another study, a composite organization achieved 97% availability across 42,000 SKUs after implementation.

As for timelines, most mid-sized manufacturers with standard processes can expect to go live within 4-6 months. For larger, more complex operations with multiple sites or custom requirements, plan for 12-18 months from kickoff to completion.

At Nuage, our implementation approach focuses on delivering value quickly. Most of our clients see tangible benefits within the first 3-4 months, with full ROI typically realized within 12-24 months. We’ve refined our methodology over 20 years to accelerate time-to-value without sacrificing quality or completeness.

How does ERP boost supply-chain resilience?

If recent global disruptions taught us anything, it’s that supply chain resilience isn’t optional—it’s essential. Modern erp for industrial manufacturing systems build this resilience through several powerful capabilities:

Multi-sourcing functionality makes it easy to maintain and quickly activate alternate suppliers when primary vendors can’t deliver. One of our food manufacturing clients used this capability to switch 40% of their ingredients to alternate sources during a major supply disruption, maintaining production while competitors shut down lines.

Early warning systems alert you to potential problems before they become crises. These alerts might flag unusual lead time variances, recurring quality issues, or integrate with external data feeds about global supply chain conditions.

Your ERP should also enable scenario planning, allowing you to model different supply disruptions and develop contingency plans. This “what-if” capability helps you prepare for challenges before they occur.

Inventory optimization balances the competing needs of minimizing carrying costs while maintaining enough safety stock to weather disruptions. Advanced algorithms in systems like NetSuite and continuously refine these calculations based on actual performance data.

Supplier collaboration features, including integrated portals, enable transparent sharing of forecasts, production plans, and inventory levels with key suppliers. This visibility helps your vendors anticipate your needs and allocate resources accordingly.

Finally, demand sensing capabilities use advanced analytics to detect early signals of demand changes, helping you adjust production and procurement plans before competitors even realize the market is shifting.

During the pandemic and subsequent supply chain crisis, our clients with modern ERP systems adapted significantly faster and experienced less severe impacts than those relying on legacy systems or manual processes.

Which deployment model fits my mid-sized plant?

For mid-sized industrial manufacturers (typically in the $50M-$500M revenue range), I generally recommend exploring cloud-based erp for industrial manufacturing solutions first. Here’s why:

Cloud deployment shifts costs from capital expenditure to operating expenditure, preserving your capital for production equipment and other strategic investments. This financial flexibility can be particularly valuable for growing mid-sized operations.

Implementation speed is another advantage—cloud deployments typically complete 30-40% faster than on-premise installations. One of our manufacturing clients went live with NetSuite in just 16 weeks, compared to their previous on-premise ERP implementation that took nearly a year.

The reduced IT burden is significant too. With vendors handling infrastructure, security patches, and updates, your IT team can focus on strategic initiatives rather than system maintenance. This is especially valuable for mid-sized manufacturers with limited IT resources.

Cloud ERP also offers best scalability, growing seamlessly as your business expands. This eliminates the hardware upgrades and complex migrations that often plague on-premise systems during growth phases.

That said, specific factors might point you toward a different model:

If your plant operates in areas with unreliable internet connectivity, a hybrid model might make more sense, keeping critical production functions on-premise while leveraging the cloud for planning and analytics.

Some manufacturers have truly unique processes requiring extensive customization. In these cases, we carefully evaluate whether your preferred cloud solution supports these needs or if an on-premise or hybrid approach would better preserve your competitive advantages.

Regulatory requirements can also influence this decision. If you must maintain certain data on-site, consider hybrid options that keep sensitive information local while leveraging cloud capabilities for other functions.

At Nuage, we never push a one-size-fits-all approach. Instead, we conduct a thorough assessment of your specific requirements, constraints, and objectives before recommending the optimal deployment model for your manufacturing operation. Our partnerships with both NetSuite and ensure we can match you with the right solution regardless of which deployment model makes the most sense for your business.

Conclusion & Next Steps

The journey to finding the right ERP for industrial manufacturing is one that will shape your company’s future for years to come. Throughout this guide, we’ve steerd the complex landscape of manufacturing ERP solutions, each with their own strengths and specializations.

Startling statistic—only 39% of manufacturing workers consider their technology very modern. This represents your opportunity to leap ahead while competitors remain stuck with outdated systems and processes. By implementing a purpose-built ERP for industrial manufacturing solution, you position yourself to overcome operational challenges while gaining significant competitive advantages.

When reflecting on what matters most in your ERP decision, keep these crucial insights in mind:

Manufacturing-specific functionality is non-negotiable. Generic ERP solutions rarely address the unique complexities of industrial manufacturing environments. Your business deserves systems with robust production planning, detailed shop floor control, integrated quality management, and proactive maintenance capabilities—features designed specifically for manufacturing operations.

Cloud deployment delivers compelling advantages for most manufacturers today. From faster implementation timelines and reduced IT burden to seamless updates and improved accessibility, cloud-based ERP creates a foundation for agility and growth. The statistics don’t lie—manufacturers are seeing real ROI from cloud transitions.

Future-ready systems support Industry 4.0 integration. Your ERP should serve as the backbone for smart factory initiatives, supporting IoT connectivity, AI-powered analytics, and that all-important digital thread connecting every aspect of your operation. The factory of tomorrow requires systems built for tomorrow’s challenges.

Implementation approach determines ultimate success. Even the most powerful system will fall short without thoughtful planning, comprehensive change management, careful data migration, and ongoing improvement processes. The journey matters as much as the destination.

At Nuage, we bring over two decades of experience helping industrial manufacturers steer digital change. Our partnerships with leading solutions like NetSuite and allow us to recommend and implement the right solution for your specific needs—never forcing a one-size-fits-all approach.

We understand the challenges you’re facing, whether you’re replacing legacy systems that no longer serve your needs, consolidating a patchwork of applications, or implementing your first comprehensive ERP solution. Our team guides manufacturers through every step of the journey, from initial requirements definition through post-implementation optimization.

Ready to explore how ERP for industrial manufacturing can transform your operations from reactive to proactive? Contact our team for a no-obligation consultation. We’ll help you assess your current state, define your future vision, and develop a practical roadmap for success that aligns with your business objectives and budget realities.

The machinery madness of modern manufacturing demands intelligent, integrated systems. With the right ERP solution and implementation partner, you can turn complexity into clarity and challenges into competitive advantages.