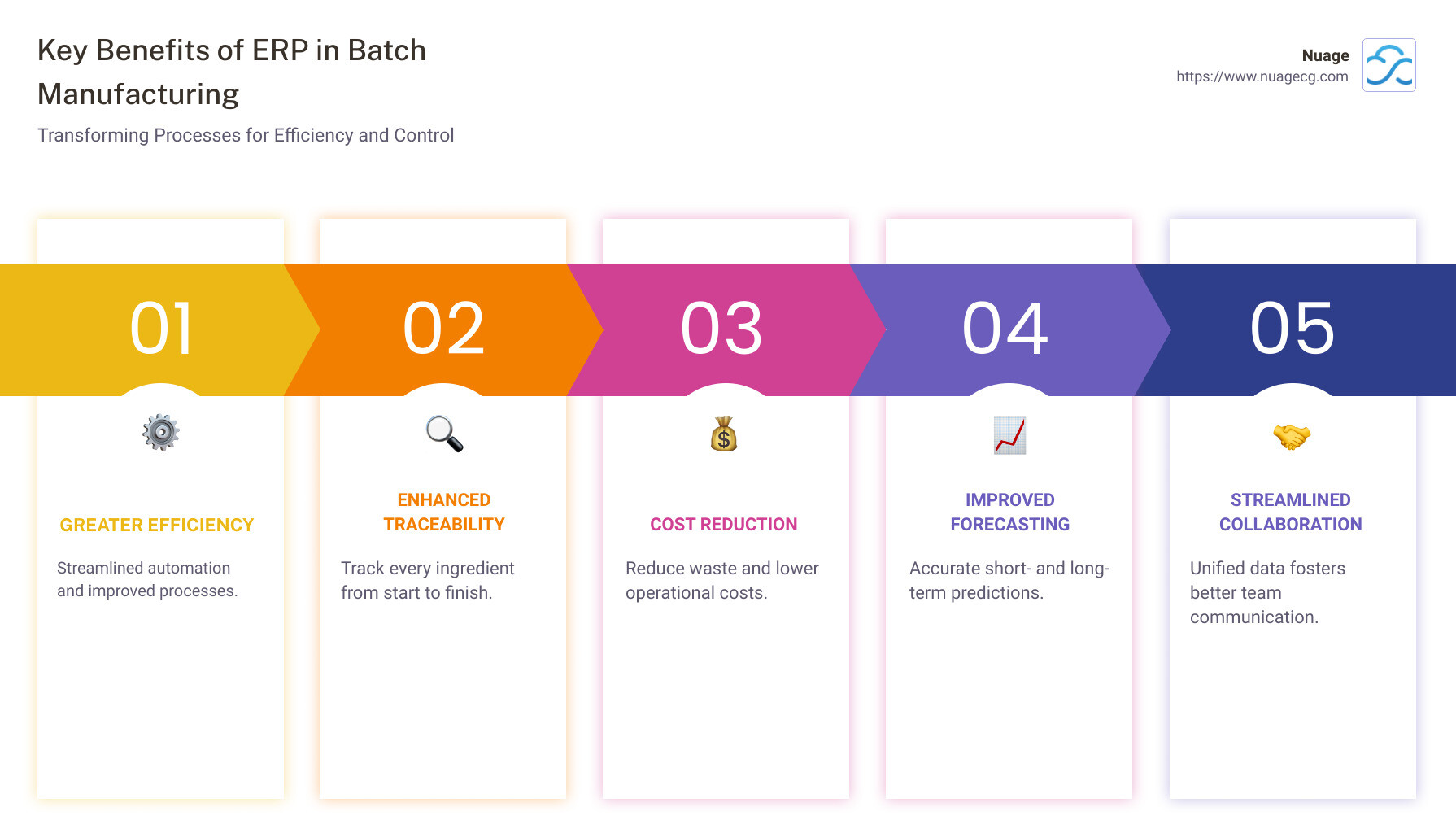

ERP for batch process manufacturing is changing the industry by enabling businesses to achieve greater efficiency, full traceability, and financial savings. For companies seeking clarity in this dynamic sector, here are the key benefits:

- Greater efficiency: Streamlined automation and improved processes.

- Improved traceability: Track every ingredient from start to finish.

- Cost reduction: Reduce waste and lower operational costs.

- Improved forecasting: Accurate short- and long-term predictions.

- Streamlined collaboration: Unified data fosters better team communication.

Batch manufacturing involves complex processes requiring precision and control. ERP systems, like those we specialize in at Nuage, are designed to meet these demands by integrating advanced traceability, improved productivity, and compliance management, ensuring manufacturers can maintain quality and regulation adherence effortlessly.

I’m Louis Balla, a partner at Nuage. For over 15 years, I’ve helped businesses harness ERP solutions like NetSuite to streamline their operations and drive growth. My expertise lies in guiding companies to smoothly transition from chaos to control using ERP for batch process manufacturing.

Understanding ERP for Batch Process Manufacturing

Batch process manufacturing is all about precision and control. It involves creating products by mixing or blending raw materials in specific quantities. Think of it like cooking a complex recipe where every ingredient and step matters. This kind of manufacturing is common in industries like food, chemicals, and pharmaceuticals.

ERP software plays a vital role in this process. It helps manufacturers manage their operations more effectively by providing tools for traceability, inventory management, and quality control.

Key Features of ERP Systems

Traceability is crucial in batch process manufacturing. With ERP systems, manufacturers can track every ingredient and product from start to finish. This ensures compliance with regulations and helps maintain high-quality standards. For example, if there’s a problem with a batch, traceability allows you to quickly identify and address the issue.

Inventory management is another important feature. ERP systems help manufacturers keep track of raw materials and finished products. This prevents overstocking or understocking and helps optimize the supply chain. With accurate inventory data, manufacturers can make informed decisions about purchasing and production.

Quality control is essential to ensure that products meet the required standards. ERP systems provide tools to monitor and manage quality throughout the production process. This helps manufacturers maintain consistency and avoid costly errors.

Benefits of ERP in Batch Manufacturing

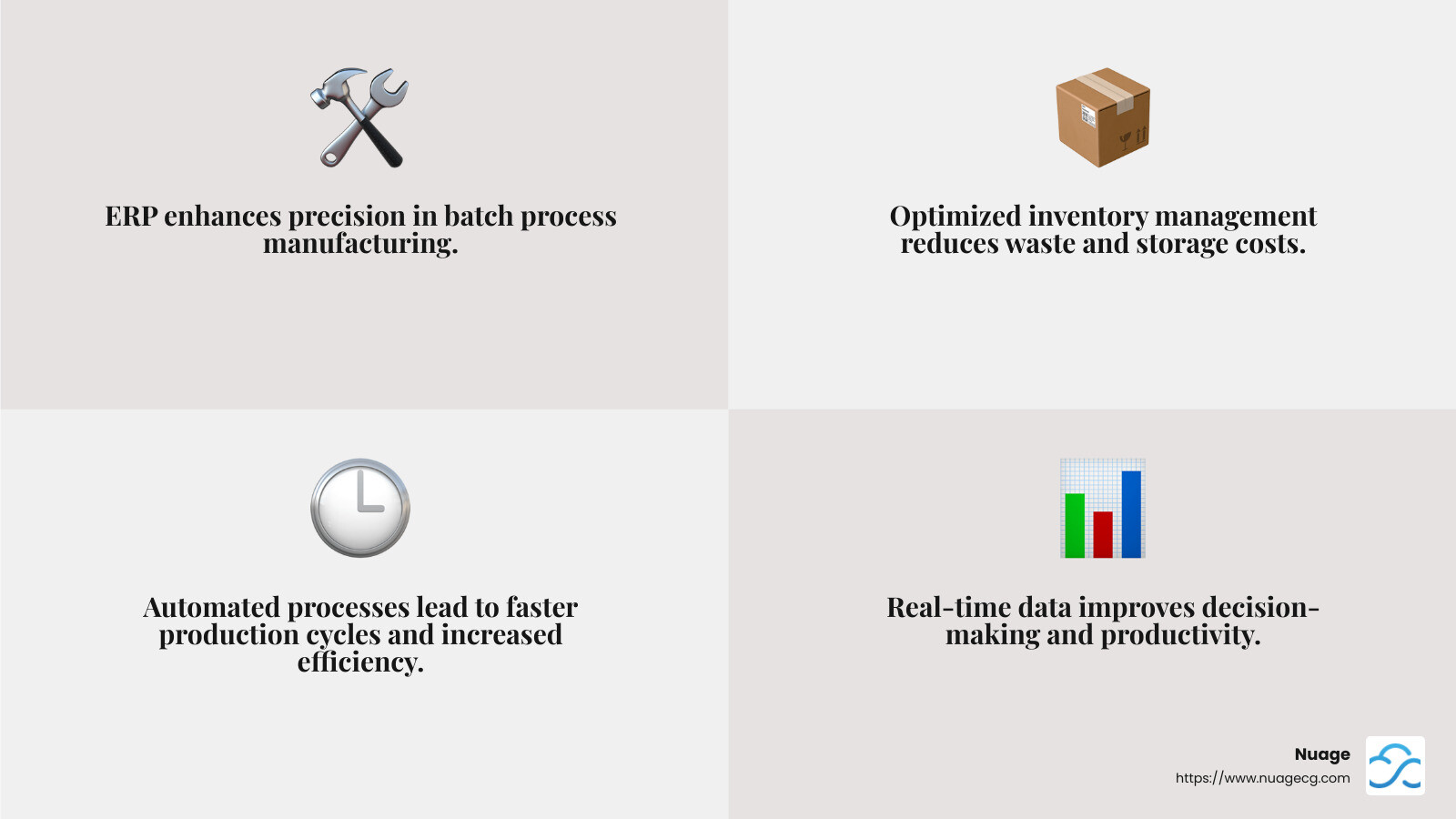

Efficiency is a major benefit of using ERP systems in batch manufacturing. By automating repetitive tasks and streamlining processes, manufacturers can save time and reduce errors. This leads to faster production cycles and improved overall performance.

Cost reduction is another advantage. ERP systems help identify inefficiencies and areas where costs can be cut. For instance, better inventory management reduces waste and lowers storage costs. Additionally, by optimizing production schedules, manufacturers can minimize downtime and maximize resource utilization.

Productivity is improved with ERP systems. By providing real-time data and insights, ERP software enables manufacturers to make better decisions and improve their operations. Employees can focus on value-added tasks rather than manual data entry, leading to higher productivity levels.

At Nuage, we understand the complexities of batch process manufacturing. Our ERP solutions like NetSuite are designed to help manufacturers achieve greater efficiency, cost savings, and improved product quality.

By embracing ERP for batch process manufacturing, companies can transform their operations and gain a competitive edge in the industry. The next section will explore how ERP systems streamline operations, improve forecasting capabilities, and improve collaboration across teams.

How ERP Transforms Batch Process Manufacturing

Streamlining Operations

In batch process manufacturing, efficiency is key. ERP for batch process manufacturing optimizes every step from raw material acquisition to finished goods. By automating inventory management, ERP systems ensure you have just the right amount of materials. This prevents overstocking and reduces waste.

Scheduling is another area where ERP shines. It helps manufacturers plan production runs more effectively, minimizing downtime and maximizing machine use. With resource management tools, you can allocate equipment and labor where they’re needed most, ensuring smooth operations.

Enhancing Forecasting Capabilities

Accurate forecasting can make or break a manufacturing business. ERP systems use demand planning and predictive analytics to anticipate future needs. This means you can adjust production schedules and inventory levels before a problem arises.

Data utilization is at the heart of improved forecasting. ERP systems gather and analyze data from all areas of your business, providing insights that help you make informed decisions. This leads to better alignment of production with market demands, reducing the risk of overproduction or stockouts.

Improving Collaboration Across Teams

Effective communication is critical in manufacturing. ERP systems improve data integration, ensuring that all departments work from the same information. This unified data source breaks down silos and fosters collaboration.

When teams have access to real-time data, they can quickly identify and solve problems. This improves problem-solving and reduces the likelihood of production delays. Improved communication also means that if one department encounters an issue, others can respond swiftly, minimizing disruption.

By integrating these capabilities, ERP systems transform batch process manufacturing into a well-oiled machine. They not only streamline operations but also improve forecasting and improve team collaboration. This holistic approach ensures manufacturers can meet customer demands efficiently and maintain a competitive edge.

In the next section, we’ll explore the top ERP solutions for batch process manufacturing, highlighting the flexibility and features of systems like NetSuite.

Top ERP Solutions for Batch Process Manufacturing

NetSuite

Cloud-Native and Comprehensive Features

NetSuite is another leading ERP solution, renowned for its cloud-native architecture. This means you get all the benefits of cloud computing, such as real-time data access and reduced IT overhead. NetSuite’s cloud-native nature ensures seamless updates and consistent performance, keeping your operations running smoothly.

NetSuite offers comprehensive features that cover all aspects of batch process manufacturing. From inventory management to order processing, NetSuite provides a holistic view of your operations. This end-to-end visibility helps manufacturers make informed decisions and optimize their processes.

Scalability is also a strength of NetSuite. As your manufacturing business expands, NetSuite can easily accommodate increased data and transaction volumes. This ensures that you can continue to rely on NetSuite as your primary ERP solution, even as your business evolves.

NetSuite offers a robust solution for batch process manufacturing. Its flexibility, scalability, and comprehensive features make it an ideal choice for manufacturers looking to streamline operations and improve their competitive edge.

Frequently Asked Questions about ERP for Batch Process Manufacturing

What is ERP in manufacturing process?

ERP, or Enterprise Resource Planning, is a software system that integrates various functions of a manufacturing business into a single, unified platform. In the context of batch process manufacturing, ERP helps manage and streamline production processes, from procurement and inventory management to quality control and compliance. This integrated management ensures that all departments can access real-time data, improving decision-making and operational efficiency.

Which ERP software is used for manufacturing industry?

n the manufacturing industry, ERP software like NetSuite is a popular choice. This platform offers centralized management capabilities that help manufacturers oversee facility operations, monitor production schedules, and maintain control over inventory levels. By providing a comprehensive view of the business, ERP solutions like NetSuite help manufacturers optimize their processes and reduce costs.

Which module in ERP system is used to manage manufacturing processes?

ERP systems are divided into modules, each handling specific aspects of business operations. For managing manufacturing processes, the Production Management module is key. This module supports batch production by automating tasks like scheduling, resource allocation, and quality checks. It ensures that manufacturing processes run smoothly, minimizing downtime and maximizing productivity. Additionally, the module provides insights into production efficiency and helps identify areas for improvement, making it essential for effective process management.

Conclusion

At Nuage, we understand the complex landscape of digital change. Our 20 years of experience in ERP solutions make us a trusted partner for businesses navigating this change. By leveraging our expertise, we help companies implement and support ERP systems that drive efficiency and growth.

Digital change is reshaping industries, and ERP systems are at the forefront of this evolution. For batch process manufacturing, ERP solutions streamline operations, improve forecasting, and improve collaboration across teams. These systems integrate various functions, providing real-time data and insights that are crucial for informed decision-making.

We specialize in helping businesses choose the right ERP software, such as NetSuite. This platform offers robust features tailored to meet the unique needs of batch process manufacturers, from inventory optimization to quality control.

Our commitment is to guide our clients through their digital change journey with confidence. We don’t just sell software; we provide solutions that align with your business goals. By partnering with us, you gain a team that prioritizes your success and helps you harness the full potential of ERP technology.

Explore how our services can transform your batch process manufacturing operations by visiting our NetSuite page. Let’s work together to steer your business towards a future of efficiency and success.