Why Food Processing Operations Demand More Than Basic ERP

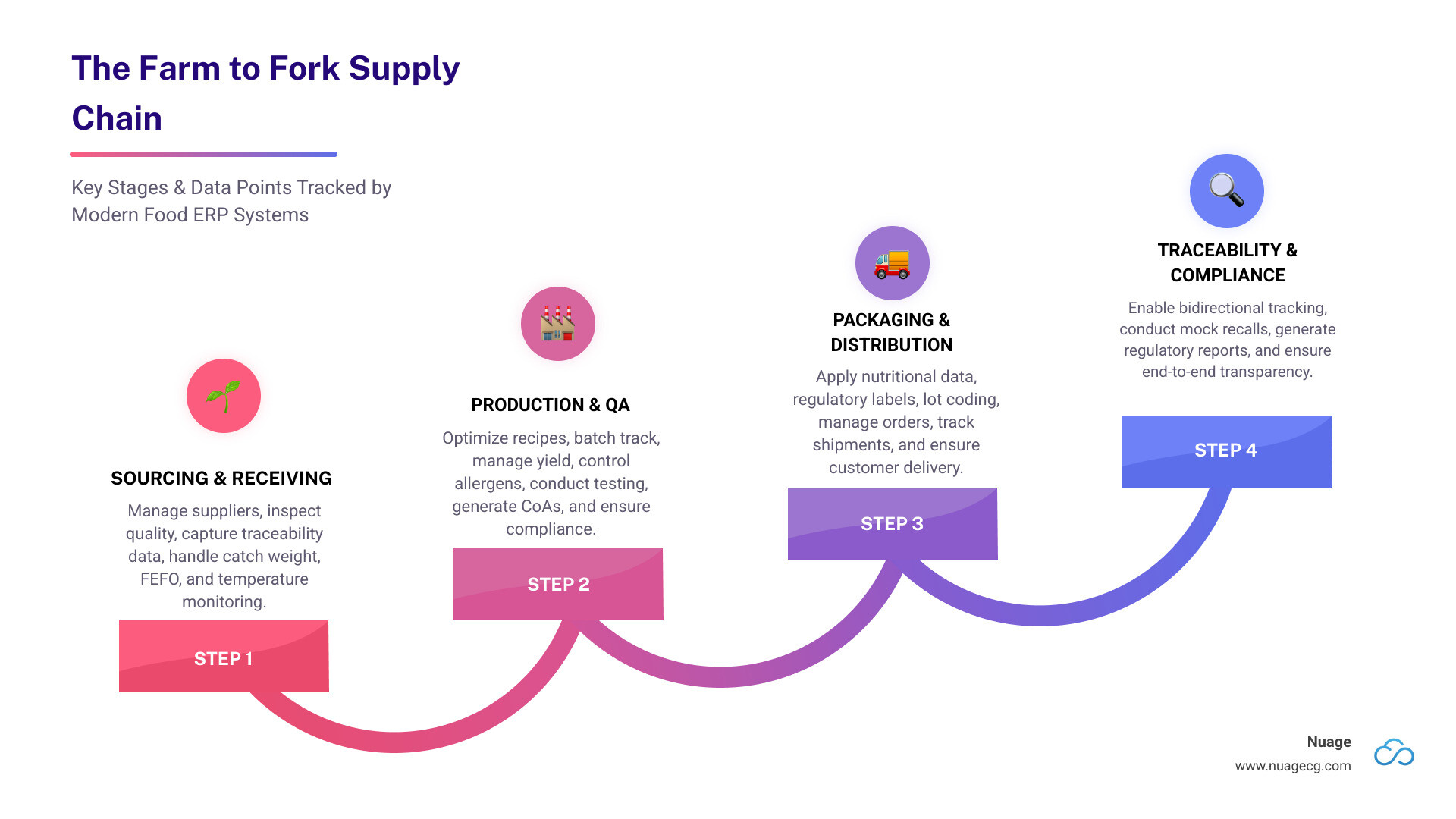

A top-tier ERP food processing software is a specialized enterprise resource planning system designed to manage the unique challenges of food manufacturing. Leading solutions like NetSuite for Food & Beverage provide a cloud-based, scalable platform with industry-specific modules to handle lot traceability, recipe management, catch weight, allergen tracking, regulatory compliance (FSMA, HACCP), and perishable inventory across the entire farm-to-fork supply chain.

The food and beverage industry contributes over $1 trillion to the U.S. GDP annually, but many companies struggle with generic software that wasn’t built for their reality. Standard ERPs lack critical capabilities like FEFO (First-Expired-First-Out) inventory protocols, multi-level batch tracking, and integrated allergen management.

The stakes are incredibly high. With around 15 million Americans having food allergies and a majority of consumers following specialized diets, a single recall or compliance failure can devastate a brand and shut down operations. Food processors must manage perishable ingredients, variable weights, complex recipes, and strict regulations like FSMA 204—complexities that generic business software simply can’t handle.

That’s where specialized ERP food processing software becomes essential. Modern solutions integrate quality control, automate compliance, optimize yield, and provide real-time visibility. The best systems are cloud-based, offering 24/7 access, automatic updates, and the scalability to grow with your business.

I’m Louis Balla, and over my 15+ years in digital change and supply chain management, I’ve seen how the right ERP food processing software transforms operations—particularly when businesses open up the full potential of platforms like NetSuite. Most food processors use only 20% of their ERP’s capabilities, leaving massive value on the table.

ERP food processing software helpful reading:

Why Food Processors Need Specialized ERP Systems

Managing a food processing operation with standard business software leads to frustration and risk. Food manufacturing has unique demands that generic ERP systems weren’t designed for, forcing companies to rely on spreadsheets and manual workarounds that create operational blind spots.

Perishable inventory challenges are a primary concern. Unlike durable goods, food products have expiration dates. Standard ERPs might handle First-In-First-Out (FIFO), but food processors need First-Expired-First-Out (FEFO) protocols to minimize spoilage and protect consumer trust. Without a specialized ERP food processing software, tracking expiration dates across multiple lots is a manual nightmare that requires automated alerts and intelligent rotation rules.

Then there’s catch weight and variable yield. A standard ERP expects fixed quantities, but food products rarely conform. A processor might buy tuna by the pound but sell it in various cuts and SKUs with different final weights. Your ERP must handle these fluctuations to provide accurate costing and inventory levels, tracking both theoretical and actual yields.

Complex recipe management is another area where basic Bills of Materials (BOMs) fall short. Food recipes require version control for reformulations, scaling capabilities that maintain ingredient ratios, and automatic nutritional calculations. A specialized system manages multiple recipe versions and ensures changes flow through to labels, costs, and compliance documents.

Allergen management risks are non-negotiable. A single cross-contamination incident can be catastrophic. Generic software treats allergens as a simple data field, but specialized ERP food processing software embeds allergen intelligence throughout the operation. It flags cross-contamination risks during scheduling, validates cleaning procedures, and ensures proper segregation in storage.

Modern consumers and regulators also demand sustainability and ESG reporting. Standard ERPs track financials but weren’t built to monitor carbon footprint, water usage, or ethical sourcing metrics. Food processors need purpose-built tools to report on environmental impact and demonstrate progress on ESG commitments.

Most critically, generic systems fail at supply chain traceability. Regulations like FSMA 204 mandate bidirectional traceability—tracing an ingredient from its source to every customer. Without integrated lot tracking and recall management tools, this is an impossible scramble through disconnected records. A mock recall exercise that should take hours can take weeks, a dangerous and potentially business-ending delay.

The inability to meet compliance ties these challenges together. Food safety regulations (HACCP, FSMA, FDA) are mandatory. Purpose-built food ERP systems integrate quality control and compliance documentation into daily workflows, making compliance routine instead of a crisis.

Key Features of a Modern ERP Food Processing Software

A modern ERP food processing software acts as the central nervous system for your operation, connecting every department in real time. It’s designed for the complex reality of food manufacturing, where details like a single batch number are critical for safety and efficiency. Let’s explore the key features.

Mastering Traceability, Compliance, and Quality Control

Food safety requires absolute precision, and this is where specialized ERPs excel.

- Lot traceability: The foundation is farm-to-fork tracking, providing bidirectional visibility of every ingredient from supplier to customer. This allows you to answer critical questions about origin and destination in minutes.

- Mock recall readiness: A quality ERP food processing software lets you run a mock recall in minutes, identifying every affected product, customer, and warehouse location. This capability is crucial for passing regulatory audits.

- Quality assurance workflows: QA is integrated into every production stage. The ERP manages inspections, tracks test results, handles non-conforming materials, and automatically generates Certificate of Analysis (CoA) documents.

- Allergen tracking and management: The system flags allergens in recipes, alerts teams to cross-contamination risks, tracks cleaning procedures, and ensures accurate labeling to protect consumers.

- FSMA compliance tools: The system maintains documentation for HACCP plans, tracks preventive controls, and generates reports for auditors, making it easier to meet regulatory requirements like those outlined in the Food Safety Modernization Act (FSMA).

Optimizing Production, Inventory, and Yield

On the production floor, a specialized ERP proves its worth by connecting planning with execution.

- Recipe and formula management: Go beyond simple ingredient lists with dynamic recipes that include instructions, quality parameters, and nutritional data. Batch scaling and version control are automated.

- Yield optimization: The system compares expected yields to actual results, helping you identify patterns and reduce waste by analyzing data from every batch.

- FEFO/FIFO inventory protocols: The ERP actively directs warehouse staff to pick products based on expiration dates, sending alerts for items nearing their shelf life and preventing costly spoilage.

- Integrated MES (Manufacturing Execution System): Real-time shop floor data on machine status, labor, and material consumption flows directly into the ERP. This makes production scheduling more accurate and responsive to disruptions.

- The NetSuite Manufacturing module unifies these capabilities on a cloud platform, ensuring you have the right materials in the right place at the right time.

Unifying Financials and the Supply Chain

The true power of an ERP is the single, unified view of your business.

- Real-time cost control: Track every cost (materials, labor, overhead) and assign it to specific batches. This enables lot-level profitability analysis to see which products and customers are most profitable.

- Demand forecasting: Modern systems use historical data, seasonality, and even AI to predict future demand, preventing overproduction and stockouts.

- Procurement automation: The system monitors inventory, generates purchase orders, and routes approvals automatically, freeing up staff to focus on strategic sourcing.

- End-to-end supply chain visibility: A single dashboard provides a complete view from supplier to customer. This visibility helps you manage disruptions proactively.

- NetSuite Inventory Management provides this unified view, updating levels in real time across all locations. When all these pieces work together on a unified NetSuite platform, you gain the confidence to make decisions based on real data.

How to Choose the Right Food ERP Solution for Your Business

Selecting the right ERP food processing software is a critical business decision. It’s about choosing a long-term partner for growth. The right choice can transform your operations, while the wrong one leads to rigid systems and integration nightmares.

Evaluating Technology: Cloud, AI, and Integration

Your ERP’s technology foundation determines its future viability.

- Cloud ERP benefits: Cloud solutions are now essential. They offer best scalability to grow with your business, accessibility for teams to work from anywhere, and cost-effectiveness by replacing large upfront capital costs with predictable subscriptions. Updates and security are handled automatically.

- Role of AI and machine learning: Modern ERPs use AI to improve demand forecasting, optimize production schedules, and even predict equipment failures, turning data into actionable insights.

- Single-vendor versus multi-system: While a “best-of-breed” approach seems appealing, integrating multiple systems often creates data silos and vendor finger-pointing. A unified platform provides a single source of truth. For global operations, a solution like NetSuite OneWorld manages multiple currencies, tax regulations, and reporting requirements seamlessly.

A Closer Look at an ERP food processing software: NetSuite

NetSuite for Food and Beverage is a leading choice because it’s a flexible platform that adapts to your business.

- Built for food and beverage sub-sectors: NetSuite provides core functionality for dairy, meat processing, baked goods, and beverages, while allowing customization for your unique processes.

- Real-time data and analytics: Get a complete, up-to-the-minute view of your entire operation on a single dashboard to track costs, profitability, and inventory.

- Limitless scalability: Start with core financials and inventory, then add manufacturing or commerce modules as you grow. The system scales with you, and updates are automatic.

- Omnichannel commerce capabilities: Manage direct-to-consumer, wholesale, and retail channels from a single platform, ensuring consistent data and customer experience.

- The extensive SuiteApps catalog offers pre-built applications to extend NetSuite’s functionality without costly custom development.

Planning for Implementation and Long-Term Success

Choosing the right software is only the first step. Successful implementation is key.

- Implementation considerations: A successful project requires careful planning, including data migration strategy, process redesign, and user training. Timelines can range from 90 days to six months or more, depending on complexity.

- Total Cost of Ownership (TCO): Look beyond licensing fees to include implementation, training, and internal resource costs. Cloud solutions often have a lower TCO over time compared to on-premise systems.

- Choosing an experienced implementation partner: The right partner understands both the software and the food industry. At Nuage, we’ve spent over 20 years guiding digital change. We act as your NetSuite Optimization Engine, helping you select, implement, and continuously optimize your system. We ensure you avoid the common trap of using only a fraction of your ERP’s capabilities, opening up the full potential of your investment.

Frequently Asked Questions about Food ERP Software

Here are straightforward answers to common questions from food processors considering a new ERP system.

How does an ERP system help with food safety and recalls?

An ERP food processing software is your command center for food safety. It provides granular lot traceability from farm to fork, enabling rapid mock recalls that identify affected products and customers in minutes. Integrated quality assurance workflows manage inspections and testing at every stage, while automated allergen tracking prevents cross-contamination. The system also centralizes documentation for FSMA compliance, turning regulatory adherence into a routine process.

What’s the advantage of a cloud-based ERP for a food business?

Cloud-based ERPs offer critical advantages for modern food businesses. Scalability allows you to add users or facilities without major IT projects. Accessibility gives your team real-time data from any device, anywhere. The cost-effective subscription model eliminates large upfront hardware costs and includes automatic updates and security. For multi-site operations, a cloud platform like NetSuite provides a single, unified view of the entire business.

How does an ERP for food processing handle industry-specific needs like catch weight?

This is a key differentiator. Unlike generic ERPs built for uniform products, a specialized ERP food processing software is designed for catch weight and variable yields. You can purchase, produce, and sell in different units of measure (e.g., buy by the case, sell by the pound). The system tracks actual weights at every step, ensuring your costing, inventory, and pricing are always accurate. It adapts to the reality of food manufacturing, rather than forcing your processes into a rigid, ill-fitting system.

Conclusion: Future-Proof Your Operations with the Right Partner

The path from farm to fork is more demanding than ever, with perishable inventories, variable catch weights, and complex regulations. Trying to manage it all with generic software is inefficient and risky. A specialized ERP food processing software is no longer a luxury; it’s essential for ensuring compliance, driving efficiency, and improving profitability.

But buying software is the easy part. A successful implementation that opens up the full power of a platform like NetSuite requires a strategic approach. It’s about configuring the system to support your unique workflows and training your team to leverage it as a competitive advantage.

This is where Nuage comes in. With over 20 years of experience in digital change, we understand both the technology and the food industry. We are your NetSuite optimization engine, partnering with you to select, implement, and support your system as your business evolves. We help you solve your challenges and build a brand that consumers trust.

Ready to stop working around your ERP’s limitations and start working with a system built for your reality? Let’s talk about what’s possible when you have the right technology and the right partner.

Get a personalized NetSuite consultation and find how we can help you open up the full potential of your operations.