Why Food Manufacturers Need More Than Off-the-Shelf Software

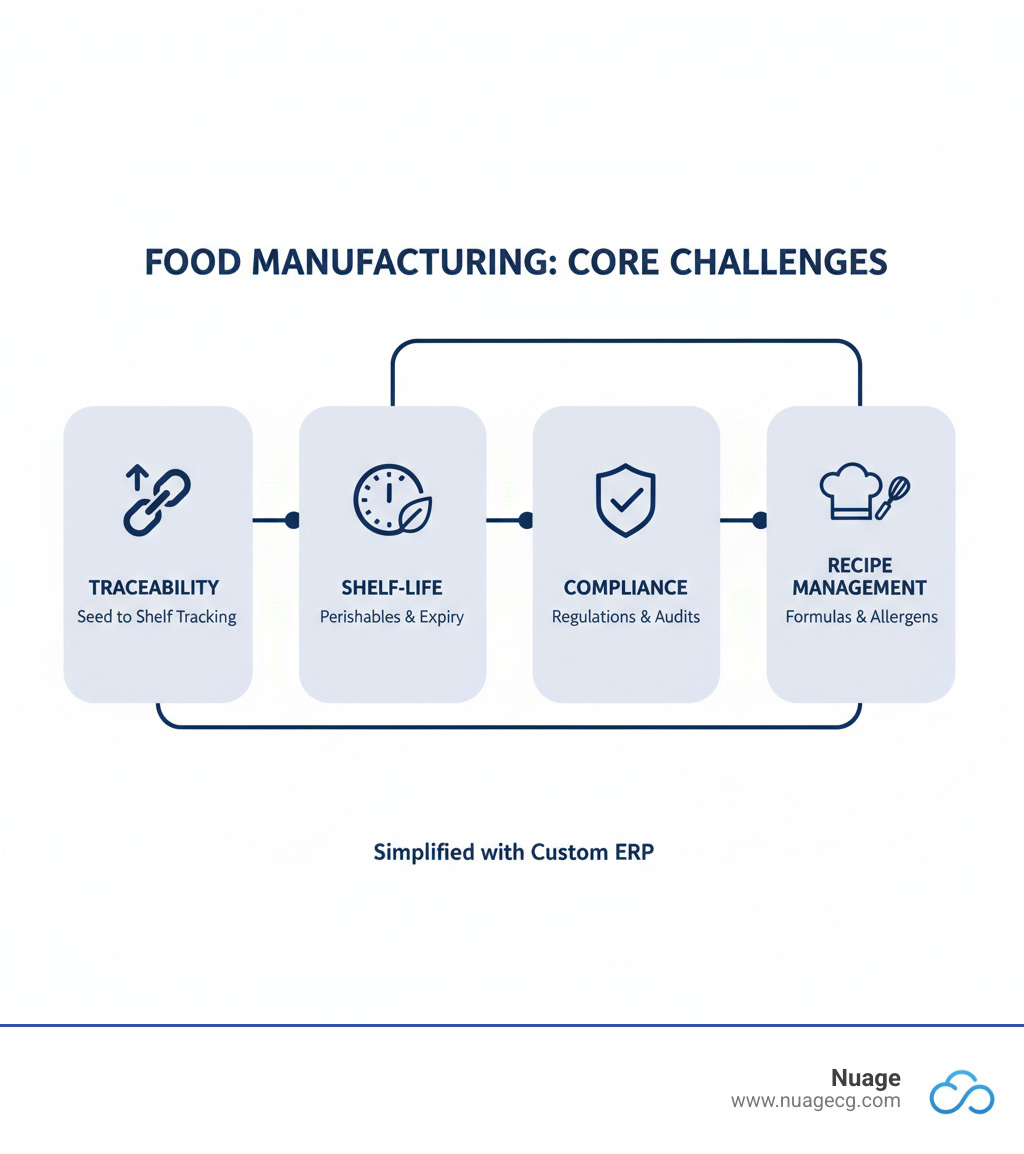

A custom ERP for food manufacturing tailors a powerful enterprise platform to your industry’s unique challenges. Instead of forcing your business into a generic system’s limitations, it provides purpose-built tools for lot traceability, shelf-life management, recipe control, regulatory compliance (FSMA, HACCP), catch weight handling, and real-time production visibility.

Many food manufacturers start with spreadsheets or generic software, only to find they can’t handle the complexities of perishable inventory, retailer shelf-life demands, or instant recall requirements. These tools lack the necessary functions for batch tracking or allergen management, forcing companies into inefficient manual processes and creating unacceptable risk.

A truly custom solution doesn’t mean building software from scratch. It means configuring a proven platform like NetSuite with industry-specific modules for your exact workflows, compliance needs, and growth plans. I’m Louis Balla, CRO and partner at Nuage. With over 15 years of experience, I help food manufacturers leverage custom ERP for food manufacturing capabilities to scale their business, focusing on NetSuite strategic alignment and third-party integrations that transform operations.

Why Generic ERPs Don’t Cut It for Food Manufacturing

Food manufacturing isn’t like other industries. You’re racing against expiration dates, tracking allergens, and maintaining documentation for FDA audits. Generic ERP systems, built for businesses with non-perishable goods, simply can’t keep up. That’s not your reality.

Perishable inventory changes everything. Every pallet has a clock ticking down to spoilage. You need systems that automatically enforce FEFO (first-expired, first-out) protocols and flag products nearing their use-by dates. Generic ERPs treat all inventory as equally valuable until it’s sold, but in your world, yesterday’s premium ingredient becomes tomorrow’s waste.

Your recipes are living documents. A product might have dozens of versions due to ingredient availability or cost changes. When you substitute an ingredient, your system must recalculate costs, update allergen declarations, and maintain version control. Standard business software wasn’t designed for this level of formula management.

Allergen tracking isn’t optional—it’s life-or-death. Your ERP must track every ingredient containing the “Big 9” allergens from receiving to packaging. It needs to flag potential cross-contact risks and generate accurate allergen statements for labels. Generic software treats ingredients as line items, not potential health hazards.

Regulatory compliance demands purpose-built tools. The Food Safety Modernization Act (FSMA) requires detailed preventive controls, hazard analyses, and traceability within hours during a recall. HACCP plans and SQF certifications require documentation that generic ERPs don’t capture. When an auditor arrives, “let me check my spreadsheets” isn’t an acceptable answer.

Batch variability and catch weights break standard systems. Your product packages don’t always have a fixed weight, and batch yields can vary. These are nightmares for ERPs designed around fixed units. You need systems that handle catch weight pricing, track actual vs. theoretical yields, and manage unit of measure conversions seamlessly.

A custom ERP for food manufacturing is specifically designed to solve these challenges. Using a platform configured for food production is the difference between constant workarounds and true operational efficiency. NetSuite’s food and beverage solutions provide a foundation that can be customized to handle your exact requirements.

Core Ingredients of a Powerful Food Manufacturing ERP

Think of your business as a complex recipe where the slightest mistake can spoil the batch. That’s why you need a custom ERP for food manufacturing that gives you complete control over your operation, from raw ingredients to finished product.

Unbreakable Traceability and Recall Readiness

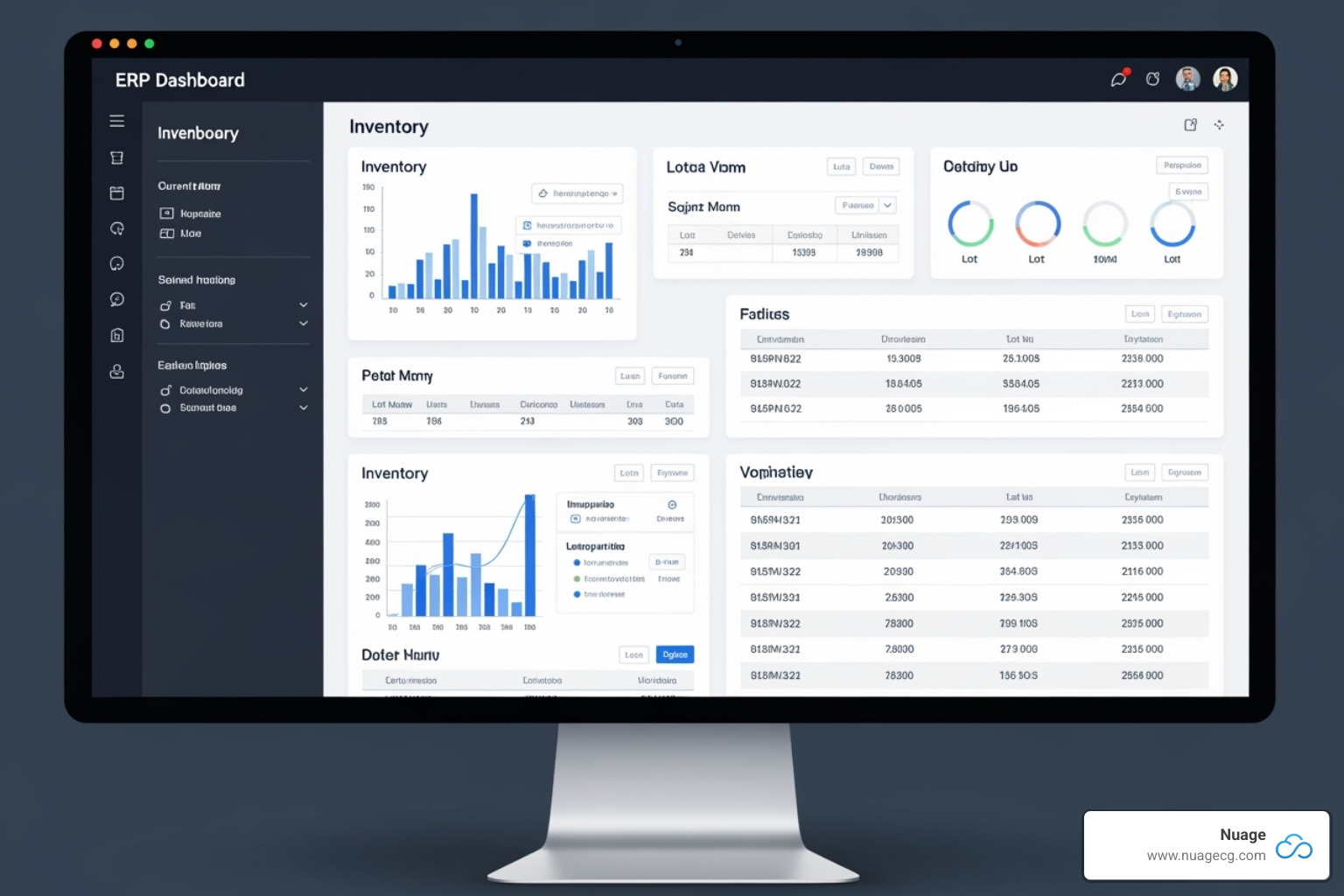

When a quality concern or potential contamination issue arises, you need answers immediately. Lot and batch tracking is the foundation of food safety, creating an unbreakable chain of custody. Your ERP must provide forward and backward traceability, allowing you to trace a finished product to its raw material origins or a raw material to every product it touched. The real test is the mock recall: can you identify every affected customer in under an hour? A properly configured NetSuite for Food and Beverage system generates these reports instantly. Specialized modules also track allergens, manage barcode generation to Global Standards 1 (GS1) standards, and store all compliance documentation in one secure location.

Precision Inventory and Production Management

Managing perishable inventory is a race against time. Your ERP must automatically enforce FEFO and FIFO protocols and provide expiration date tracking with automated alerts to dramatically reduce waste. Material Requirements Planning (MRP) takes this further, using data-driven forecasting to determine what materials you need and when, preventing both shortages and excess stock. By capturing real-time production data, you can focus on yield optimization and waste reduction. The system must also handle catch weight management for variable-weight products, integrating these fluctuations into inventory, costing, and sales without manual work. Real-time stock levels across all locations prevent production disruptions and ensure smooth operations.

Streamlined Compliance and Quality Control

Regulatory compliance in food manufacturing is non-negotiable. A custom ERP for food manufacturing embeds quality control and allergen tracking to meet stringent requirements like FSMA, HACCP, and SQF without separate systems. Quality control checkpoints at every stage ensure consistency and catch problems early, while the system automatically generates comprehensive audit trails for inspections. Your ERP should also integrate nutritional analysis and product labeling compliance, automatically generating FDA-compliant nutrition labels that reflect your actual formulations. This saves time and eliminates the risk of costly labeling errors. The right system makes compliance a natural part of your workflow, not a burden.

Building Your Custom ERP for Food Manufacturing

Building a custom ERP for food manufacturing is like designing a professional kitchen: you start with a solid foundation and configure it to match your exact workflow. You get proven reliability with specialized features that make it uniquely yours.

Platform vs. Point Solution: The Foundation of Your System

Many food manufacturers struggle with a patchwork of disconnected software. A unified, scalable platform like NetSuite for Food and Beverage is a better approach. Its modular architecture lets you implement what you need today and add functionality as you grow. Modern platforms emphasize configuration over customization, using no-code tools to adapt the system without complex development. This means faster changes and easier maintenance. Open APIs are the secret ingredient, allowing your ERP to communicate with other systems and future-proofing your investment by making it a central hub for your technology stack.

Integrating Your Entire Business Ecosystem

The real power of a custom ERP for food manufacturing emerges when it connects every part of your operation. Data flows automatically, eliminating manual entry and giving everyone access to real-time information. Your ERP should be a central hub that integrates with:

- Accounting: Sync financials with systems like QuickBooks or Sage Intacct for accurate, real-time cost of goods sold and faster financial close.

- E-commerce: Connect to platforms like Shopify or Amazon to automate order flow. NetSuite’s SuiteCommerce creates a unified omnichannel experience.

- CRM: Provide a 360-degree view of customers, giving sales and service teams access to order history, production schedules, and shipment tracking.

- Warehouse and Shop Floor: Integrate with a Warehouse Management System (WMS), scales, and labeling equipment to ensure real-time accuracy from the warehouse floor to the production line.

- EDI: Automate communication with major retail partners to streamline compliance and order processing.

Cloud vs. On-Premise: Choosing Your Deployment

Where your ERP lives affects costs, maintenance, and accessibility. The choice between cloud and on-premise is critical.

Cloud-based ERP has become the standard for most food manufacturers. It offers predictable subscription pricing, instant scalability, and access from any device. The provider handles security, backups, and maintenance, reducing the burden on your IT team and typically resulting in a lower Total Cost of Ownership (TCO).

On-premise deployment gives you complete control over your data and infrastructure but requires a significant upfront investment in hardware and licenses. Your IT team is responsible for all security, maintenance, and upgrades, which often leads to a higher TCO over time.

| Feature | Cloud-Based ERP | On-Premise ERP |

|---|---|---|

| Cost Structure | Predictable subscription pricing | Higher upfront investment plus ongoing maintenance costs |

| Scalability | Add users and modules instantly | Limited by hardware capacity, requires infrastructure investment |

| Accessibility | Access anywhere on any device with internet | Limited to internal network, requires VPN setup for remote access |

| Maintenance | Vendor handles everything, automatic updates | Your IT team responsible for all updates and maintenance |

| Data Control | Vendor manages infrastructure and security | Complete control over data location and security protocols |

| Security | Enterprise-grade security managed by vendor | Your team responsible for all security measures and patches |

| Implementation | Faster deployment with less infrastructure setup | Longer timeline due to hardware installation and configuration |

| IT Resources | Minimal internal IT burden | Requires dedicated IT staff for ongoing management |

The Implementation Roadmap: From Plan to Go-Live

Implementing a custom ERP for food manufacturing is a major project, but a clear roadmap and an experienced partner ensure a smooth journey. Careful planning and the right guide make all the difference.

Assembling Your Team and Defining Requirements

A successful implementation begins with understanding your current state. This is not just an IT project; stakeholder involvement from production, quality, finance, and sales is crucial. These are the people who know your daily pain points. By defining your business processes, we map how work actually flows, identifying bottlenecks and redundancies. This analysis helps create a prioritized feature checklist and a realistic budget, ensuring the new ERP solves the right problems.

Choosing a Partner for your custom ERP for food manufacturing

The right implementation partner is critical. Industry expertise is essential—your partner must understand the nuances of food manufacturing, from FEFO inventory to catch weight handling and FDA audit requirements. A structured implementation methodology keeps the project on track, while a clear data migration strategy prevents one of the most common pitfalls. Finally, comprehensive training and support ensure your team adopts the new system effectively. As a NetSuite Optimization team, we specialize in helping food manufacturers select, implement, and continuously improve their NetSuite environment, acting as a partner to ensure you get maximum value from your investment.

The Go-Live Process and Beyond

Going live is a milestone, not the finish line. The process begins with system configuration, where the ERP is custom to your defined business processes. Next, User Acceptance Testing (UAT) puts the system through its paces, with your team testing real-world scenarios to validate all requirements. A phased rollout can minimize disruption by implementing modules or locations sequentially. Post-launch support and continuous improvement are where the real journey begins. Regular feedback and optimization ensure your ERP evolves with your business, leveraging new NetSuite features to drive efficiency and compliance.

Frequently Asked Questions about Custom Food Manufacturing ERPs

When considering a custom ERP for food manufacturing, several common questions arise. Here are honest answers based on our experience.

How long does a custom ERP implementation take for a food manufacturer?

A typical implementation takes between 4 and 12 months. The final timeline depends on several factors:

- Project Complexity: The number of modules and integrations required.

- Company Size: A single facility will be faster than a multi-site operation.

- Data Migration: Cleaning and organizing data from legacy systems can be time-consuming.

- Team Availability: The project moves fastest when your internal stakeholders can prioritize it.

Rushing the process to meet an arbitrary deadline is a common mistake that often creates more problems than it solves.

Can an ERP really handle my unique recipes and batch processes?

Yes, but only a system designed for the food industry. A custom ERP for food manufacturing includes sophisticated formula and recipe management modules that handle:

- Version Control: Track recipe changes over time and roll back if needed.

- Ingredient Substitutions: Manage supplier changes or reformulations while updating costs and allergens.

- Dynamic Batch Scaling: Automatically adjust ingredient ratios for different production quantities to ensure consistency.

- Accurate Costing: Gain real-time visibility into margins based on current ingredient prices.

Allergen tracking and nutritional analysis are integrated directly into the recipe system, ensuring compliance and consumer safety.

What is the typical cost of a custom ERP for food manufacturing?

ERP costs vary widely, much like the cost of a house. The total investment depends on several key factors:

- User Count: Most licenses are priced per user.

- Required Modules: You pay for the functionality you need now and can add more as you grow.

- Implementation Services: This includes project management, data migration, configuration, and training.

- Deployment Model: Cloud solutions (like NetSuite) typically use a subscription model, while on-premise requires a large upfront investment.

We always focus on Total Cost of Ownership (TCO). Cloud ERPs often have a lower TCO because you avoid costs for server maintenance, updates, and dedicated IT staff. We provide a transparent cost breakdown based on your specific requirements to ensure the solution delivers real value and a strong ROI.

Conclusion

Running a food manufacturing business means juggling perishable inventory, complex recipes, and strict regulations. Generic software simply can’t keep up.

A custom ERP for food manufacturing transforms these challenges into competitive advantages. It delivers complete traceability, precision inventory management that minimizes waste, and automated compliance tools that provide real-time visibility across your entire operation.

Importantly, “custom” doesn’t mean building from scratch. It means configuring a powerful, proven platform like NetSuite to match your exact workflows. You get the reliability of enterprise-grade software with the flexibility to handle your unique recipe for success.

At Nuage, our NetSuite Optimization team acts as your strategic partner. We help you select, implement, and continuously improve your system to ensure it fits your business perfectly. Your operation is too complex for a one-size-fits-all solution.

Ready to build an ERP that works as hard as you do? Contact Nuage’s NetSuite optimization team to start the conversation.