Why Manufacturing Companies Are Moving to the Cloud

Cloud based erp solutions for manufacturing are changing how companies manage production, inventory, and supply chains. These systems deliver comprehensive business management through internet-based software that vendors host and maintain, eliminating the need for on-premise servers and IT infrastructure.

Top cloud ERP benefits for manufacturers:

- Real-time visibility across production, inventory, and finances

- Automatic updates and security patches managed by the vendor

- Lower upfront costs with subscription-based pricing models

- Mobile access for shop floor data collection and remote management

- Scalable architecture that grows with your business needs

- Built-in compliance tools for regulatory requirements like FDA and REACH

The shift to cloud ERP is accelerating as manufacturers face labor shortages and supply chain disruptions. According to research, customers expect to save over $1.5 million per year, with every affected employee re-tasked to higher-skilled positions.

Modern cloud based erp solutions for manufacturing support multiple production modes – from make-to-order and engineer-to-order to batch processing and mixed-mode operations. Leading platforms like NetSuite and offer specialized manufacturing modules including shop floor control, quality management, and supply chain planning.

I’m Louis Balla, and I’ve spent over 15 years helping manufacturers optimize their ERP systems and steer digital change challenges. My experience building and integrating third-party applications with cloud based erp solutions for manufacturing gives me deep insight into the practical benefits and implementation problems that manufacturing teams face.

Easy cloud based erp solutions for manufacturing word list:

Understanding Cloud-Based ERP Solutions for Manufacturing

The journey of manufacturing software evolved from basic mainframe computers in the 1960s to Material Requirements Planning (MRP) systems, and finally to the comprehensive ERP systems that power today’s smart factories. This evolution reflects manufacturing’s increasing complexity, and cloud based erp solutions for manufacturing have emerged as the answer to managing that complexity effectively.

What is a cloud based erp solutions for manufacturing?

Cloud based erp solutions for manufacturing are complete business management toolkits delivered through the internet rather than installed on your servers. These systems bring together production planning, inventory management, quality control, and financial reporting into one unified platform that your vendor hosts and maintains.

The magic happens through Software-as-a-Service (SaaS) architecture. You access powerful software through your web browser, with all processing happening on your vendor’s servers. It’s built on multi-tenant architecture – like a secure apartment building where multiple companies share infrastructure while keeping their data completely separate.

True cloud based erp solutions for manufacturing are designed from the ground up for cloud deployment, not legacy systems with web interfaces. Genuine Cloud ERP Systems deliver superior performance compared to those “fake clouds” that simply add web interfaces to outdated backends.

Modern cloud manufacturing ERP systems excel at connecting with IoT sensors on your shop floor, creating seamless real-time data flow from production equipment. This supports Industry 4.0 initiatives and enables AI-driven manufacturing optimization.

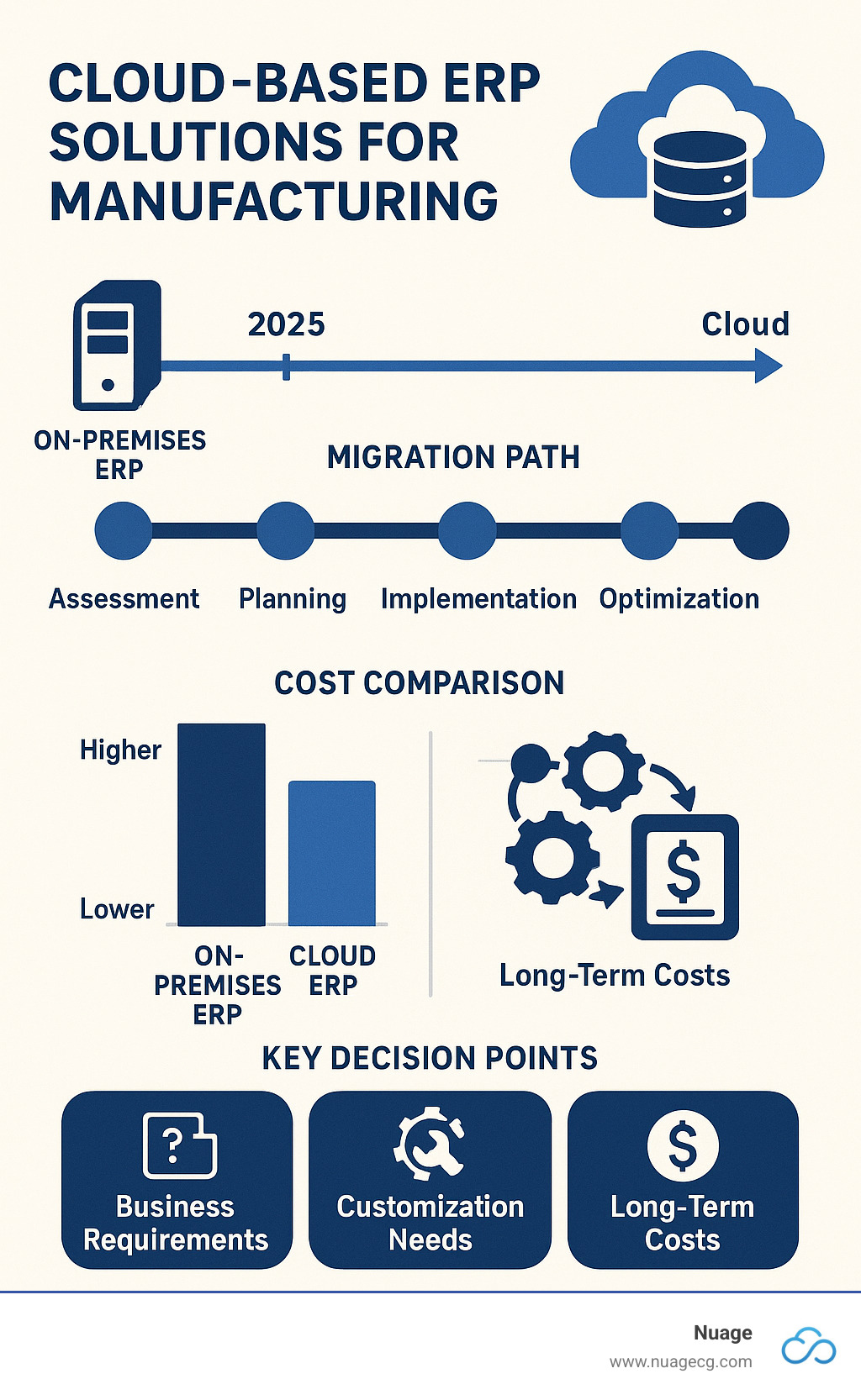

How does cloud based erp solutions for manufacturing differ from on-premise?

The biggest difference is shifting from large upfront capital expenses (CapEx) to predictable monthly operational expenses (OpEx). Instead of massive license and server investments, you pay manageable subscription fees.

Your vendor handles all maintenance – server upkeep, security patches, and system updates happen automatically. On-premise systems require dedicated IT staff and significant infrastructure investment.

Scalability becomes effortless with cloud solutions. Need more users during busy season? Done in minutes. On-premise systems require hardware purchases and lengthy deployment cycles.

Global access changes everything for manufacturers with multiple locations. Cloud platforms provide consistent access from anywhere with internet connectivity, while on-premise systems often struggle with remote access.

According to scientific research on SaaS scalability, this reduced IT burden is particularly valuable for manufacturers who want to focus resources on core production activities rather than managing technology infrastructure.

Core Benefits & Must-Have Modules

When manufacturers make the leap to cloud based erp solutions for manufacturing, they’re not just upgrading software – they’re changing how their entire business operates. The benefits extend far beyond cost savings, creating improvements from shop floor efficiency to customer satisfaction.

Key benefits manufacturers realise with cloud based erp solutions for manufacturing

Real-time data visibility is perhaps the most game-changing benefit. Instead of waiting until week’s end to find production bottlenecks, you know about them immediately. Manufacturing managers can spot brewing issues while there’s still time to fix them.

Scalability without massive infrastructure investment makes business owners smile. Design Ready Control scaled from 30 to over 300 employees with their cloud ERP system scaling alongside them – no server rooms or IT headaches required.

Labor reallocation to higher-value activities helps solve manufacturing labor shortages. When routine paperwork becomes automated, experienced workers focus on problem-solving and process improvement. Companies using report that every employee affected by implementation moved to more skilled positions.

Compliance automation removes manufacturing’s biggest headaches. Instead of scrambling before audits or worrying about FDA, REACH, or TSCA requirements, these controls become built into daily workflows.

Supply chain optimization becomes possible when all data lives in one connected system. When demand planning, supplier management, and logistics communicate seamlessly, amazing things happen to your bottom line.

Essential manufacturing modules

Production planning and scheduling modules balance customer demands against actual delivery capacity, considering material availability and machine capacity. The best systems let you run “what-if” scenarios before committing to rush orders.

Inventory control and warehouse management provide real-time visibility into actual stock levels. No more surprise stockouts or embarrassing customer conversations about delayed shipments. Modern systems include barcode scanning and mobile data collection.

Bill of Materials (BOM) management tracks how products are built and manages engineering changes with proper approval workflows. This becomes critical for complex assemblies or frequent product modifications.

Shop floor control connects your ERP system directly to production floor activities. Workers can report progress, record quality measurements, and update work orders in real-time using rugged manufacturing tablets.

Quality management modules integrate inspection plans, statistical process control, and corrective action workflows into daily operations, creating complete traceability from raw materials through finished goods.

For specialized processes, modules like ERP for Batch Manufacturing provide recipe management, yield tracking, and regulatory compliance specific to process industries.

Selecting & Implementing the Right Cloud ERP

Finding the perfect cloud based erp solutions for manufacturing doesn’t have to be overwhelming. After helping hundreds of manufacturers through this journey over 20+ years, success comes down to asking the right questions and following proven implementation strategies.

You’re not just buying software – you’re investing in a platform that will run your entire manufacturing operation.

Vendor evaluation & shortlisting

Functional fit matters more than flashy features. Generic business software can’t handle manufacturing complexity. Your ERP system needs to understand multi-level BOMs, manage complex production scheduling, and integrate seamlessly with shop floor equipment.

Roadmap alignment is where many manufacturers make critical mistakes. You want a vendor whose development priorities match your business direction. Look for platforms actively investing in AI-driven planning, IoT integration, and advanced analytics.

Ecosystem strength determines how well your ERP integrates with other systems. Manufacturing requires robust APIs, pre-built connectors, and active partner networks. This flexibility becomes crucial when adding specialized tools or connecting to customer systems.

Partner expertise can make or break implementation. Look for certified partners with deep industry experience in your specific manufacturing type. Their expertise in navigating common pitfalls is worth more than lower hourly rates.

Best practices for deploying cloud based erp solutions for manufacturing

Resist customization temptation. Modern cloud ERP systems offer extensive configuration options that meet most manufacturing requirements without custom code. Standard configuration keeps you on the vendor’s upgrade path and reduces maintenance headaches.

Phase your rollout strategically to minimize production disruption. We recommend starting with financial management and basic inventory control before tackling complex production planning. This lets teams build confidence while maintaining operational stability.

Training is where implementations often fail. Generic overviews don’t help production supervisors manage work orders or quality managers track non-conformances. Invest in role-based training addressing specific job functions.

Measure what matters from day one. Establish baseline metrics for inventory turns, on-time delivery, and production efficiency before starting. Track improvements throughout deployment to validate expected benefits.

For detailed implementation planning, our comprehensive guide on ERP Implementation Manufacturing Industry covers steps that ensure project success.

Comparing Leading Cloud ERP Platforms for Manufacturers

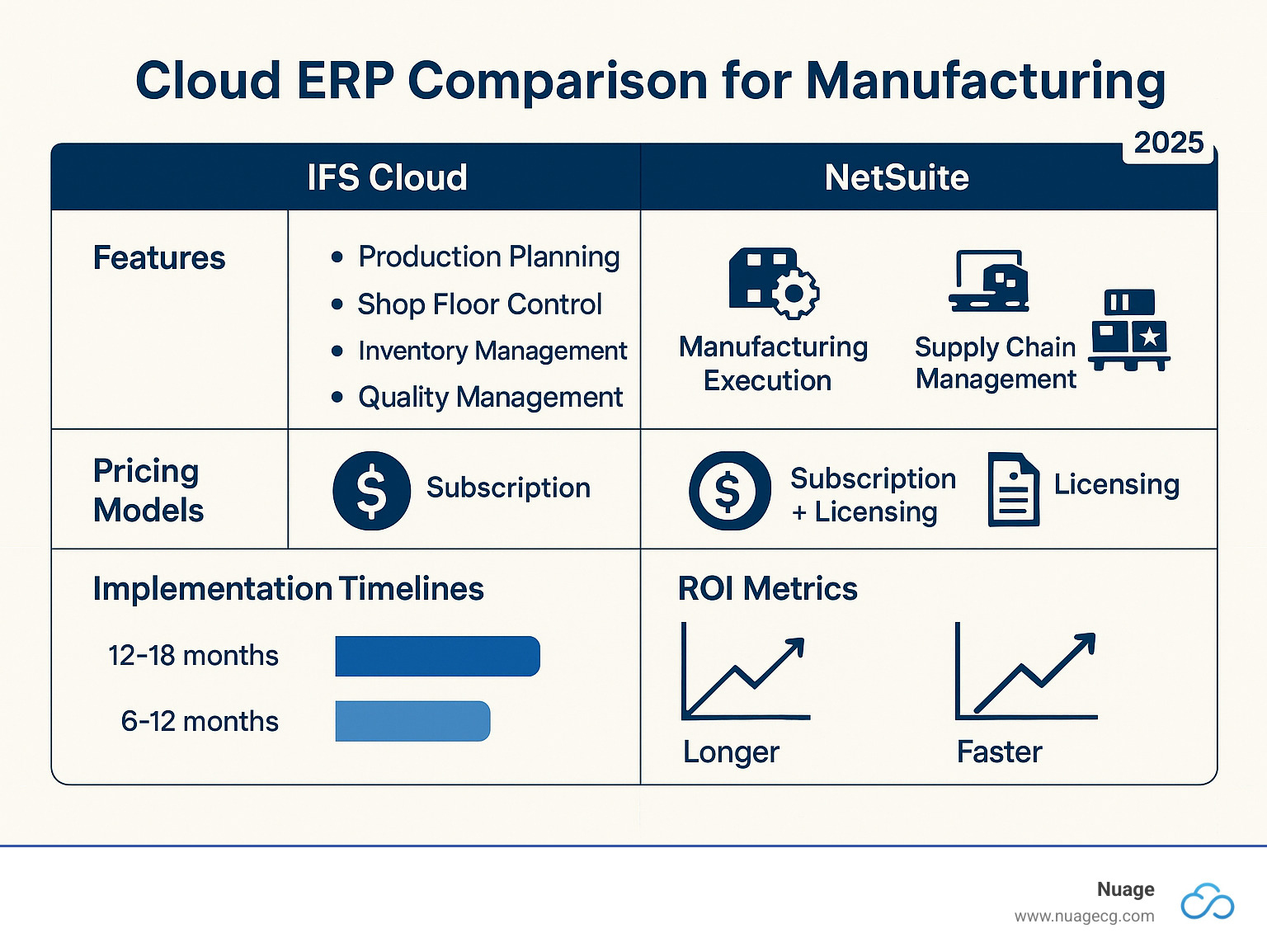

When evaluating cloud based erp solutions for manufacturing, two platforms consistently emerge as leaders: NetSuite. Both offer comprehensive manufacturing functionality, but each brings distinct strengths serving different manufacturing needs.

After helping hundreds of manufacturers over 20+ years, we’ve learned the “best” platform depends on your specific operational requirements, industry regulations, and growth plans.

overview

excels for manufacturers in complex, regulated environments where compliance isn’t optional. The platform supports mixed-mode manufacturing environments where companies produce discrete products alongside process-based goods.

AI-powered capital planning capabilities help manufacturers make smarter investment decisions by analyzing historical data and market trends to maximize ROI while managing risk.

Regulatory compliance workflows are built directly into the system. Whether dealing with REACH regulations in Europe, TSCA requirements in the US, or FDA compliance for food and pharmaceuticals, these workflows guide users through necessary steps automatically.

End-to-end traceability extends from initial design through after-sales service, with integrated quality management maintaining complete audit trails. This detail level is essential for aerospace, life sciences, and food & beverage industries.

NetSuite Manufacturing Cloud overview

NetSuite provides a unified cloud platform eliminating traditional silos between manufacturing, sales, and finance. This integration is valuable for manufacturers selling directly to customers or managing complex distribution networks.

Global distribution requirements planning (DRP) supports complex multi-location manufacturing without requiring separate systems for each facility. This becomes crucial as manufacturers expand internationally.

Mobile shop floor applications are designed for harsh manufacturing environments, not adapted from office software. Workers collect real-time data and update work orders using tablets that withstand production floor conditions.

Advanced supply chain management includes automated procurement learning from historical patterns, demand planning adjusting to seasonal variations, and supplier collaboration tools improving communication.

Real-time dashboards and analytics provide immediate visibility into production performance and financial metrics on the same screen, helping managers understand whether production targets are profitable.

Both platforms offer strong manufacturing capabilities, but choice depends on your industry requirements, regulatory environment, and existing technology infrastructure.

Real-Time Data, Compliance & Future Scalability

The true power of cloud based erp solutions for manufacturing emerges when companies move beyond basic data collection to intelligent analytics and automated compliance. After helping manufacturers for over two decades, we’ve seen how the right analytics approach can transform reactive firefighting into proactive optimization.

Leveraging analytics within cloud based erp solutions for manufacturing

Predictive maintenance has become a game-changer for manufacturers tired of unexpected equipment failures. Your cloud ERP system continuously monitors vibration patterns, temperature readings, and operating hours from production equipment. Instead of waiting for that critical machine to break down during your busiest production week, you get early warnings that let you schedule maintenance during planned downtime.

The beauty of demand forecasting algorithms in modern cloud systems lies in their ability to learn from your unique business patterns. These systems don’t just look at last year’s sales numbers – they incorporate seasonal trends, market indicators, and even weather patterns that might affect demand. One of our food manufacturing clients finded their ice cream sales correlated with local weather forecasts three days out, something their old system never would have caught.

Self-service business intelligence puts the power of data analysis directly into the hands of your production managers and quality engineers. No more waiting for IT to create reports or wondering if you’re looking at yesterday’s numbers. Modern cloud based erp solutions for manufacturing include intuitive drag-and-drop tools that let your team build custom dashboards and get real-time answers to production questions.

The shift from reactive to proactive management happens when your system sends alerts the moment something needs attention. Quality measurements exceeding control limits, production rates falling behind schedule, or inventory levels approaching reorder points – you know immediately instead of finding out at the end of the shift.

Staying compliant & audit-ready

Regulatory traceability requirements seem to multiply every year, but cloud ERP systems make compliance management much more manageable. Your system automatically tracks every lot from raw material receipt through finished goods shipment, creating an unbreakable chain of documentation that auditors love to see.

Electronic records management eliminates those frantic searches through filing cabinets when auditors arrive. Every batch record, quality certificate, and supplier document gets stored securely in the cloud with full audit trails. Systems that meet FDA 21 CFR Part 11 requirements include electronic signatures and tamper-proof documentation that actually simplifies compliance rather than complicating it.

The real efficiency gain comes from automated compliance workflows that embed regulatory requirements directly into your production processes. Food manufacturers can set up automatic holds on products pending test results, while pharmaceutical companies can enforce batch genealogy requirements before any finished goods leave the facility. The system won’t let you skip steps or forget critical documentation.

Quality audits become almost routine when everything is centralized and searchable. Instead of spending days gathering documents, auditors can quickly access batch records, supplier certifications, and deviation reports through secure system access. We’ve seen audit preparation time drop from weeks to hours with the right cloud ERP implementation.

For manufacturers ready to accept these advanced capabilities, our Digital Change for Manufacturers: A Step-by-Step Guide provides practical frameworks for moving from basic data collection to intelligent analytics. The latest research on TCO savings shows that companies leveraging these advanced features see significantly higher returns on their cloud ERP investments.

Frequently Asked Questions about Cloud ERP for Manufacturing

Let’s address the most common questions from manufacturers considering cloud ERP. After 20+ years helping companies steer digital change, these topics come up in nearly every conversation.

What is the typical cost and ROI timeline?

Investment in cloud based erp solutions for manufacturing varies by company size, required modules, and operational complexity. Most manufacturers see positive returns within 12 to 18 months.

The subscription model eliminates painful upfront capital investments. Instead of massive license and hardware checks, you get predictable monthly costs scaling with business growth.

Research shows cloud ERP delivers about 13% lower total cost of ownership compared to on-premise systems, factoring in hidden costs like hardware maintenance, IT support, and expensive upgrade projects.

ROI comes from multiple directions – better inventory management means less cash tied up in stock, reduced administrative overhead frees teams for higher-value work, and improved production efficiency directly impacts your bottom line.

Can cloud ERP handle make-to-order and process manufacturing together?

Absolutely. Modern cloud based erp solutions for manufacturing excel in this area. Both NetSuite and handle mixed-mode operations within the same system.

You might have standard make-to-stock products, custom make-to-order configurations, and process manufacturing for chemical components. Traditional systems force separate modules or systems. Modern cloud ERP handles all seamlessly.

particularly excels here, supporting engineer-to-order, configure-to-order, make-to-order, make-to-stock, and batch process manufacturing simultaneously using different planning methodologies and production workflows.

How secure is my production data in the cloud?

Leading cloud ERP vendors invest far more in cybersecurity than most individual manufacturers could afford. These platforms include multi-layered security with encryption, sophisticated access controls, and continuous monitoring exceeding most on-premise systems.

Companies like NetSuite maintain dedicated security teams whose entire job is protecting your data. They conduct regular penetration testing and maintain compliance certifications like SOC 2 Type II and ISO 27001.

Data backup and disaster recovery capabilities are built into the service. If your server room floods or catches fire, your cloud data remains safe and accessible from anywhere.

Your production data is likely more secure in properly managed cloud environments than in your own data center, unless you have substantial IT security teams and budgets.

Conclusion

The journey toward cloud based erp solutions for manufacturing isn’t just about switching software—it’s about changing how your entire operation runs. From the shop floor to the C-suite, these systems create ripple effects that touch every part of your business. Better inventory control means less cash tied up in stock. Faster order processing translates to happier customers. Real-time data visibility enables decisions that actually move the needle.

We’ve watched this change happen hundreds of times over our 20+ years in digital change. The manufacturers who succeed aren’t necessarily the ones with the biggest budgets or the most technical expertise. They’re the ones who approach ERP selection with clear goals and realistic expectations about what the technology can and can’t do.

That’s where our unbiased advisory approach makes a real difference. We don’t wake up each morning trying to sell you a particular software package. Instead, we focus on understanding your unique manufacturing challenges and matching them with the right solution—whether that’s NetSuite, , or another platform entirely.

The manufacturing world keeps throwing new curveballs. Supply chains get disrupted. Regulations change overnight. Skilled workers become harder to find. Cloud based erp solutions for manufacturing won’t solve every problem, but they create a foundation that’s flexible enough to adapt as your challenges evolve.

What excites us most is seeing manufacturers find capabilities they didn’t know they needed. A food processor realizes they can track ingredients from farm to finished product. A metal fabricator finds they can predict equipment failures before they happen. A pharmaceutical company streamlines their compliance reporting from weeks to hours.

The best time to start your cloud ERP journey was probably yesterday. The second-best time is today. Whether you’re exploring NetSuite ERP for Manufacturing or considering other options, the key is taking that first step with confidence.

Ready to see what cloud based erp solutions for manufacturing can do for your operation? Let’s talk about your specific challenges and explore solutions that make sense for your business. After all, we’re not just consultants—we’re your NetSuite Optimization Engine, committed to maximizing the value of your ERP investment for years to come.