Why Food & Beverage Software Systems Matter More Than Ever

Food and beverage software systems are specialized technology platforms designed to manage the unique operational challenges of the F&B industry. As the global market grows towards a projected $8.9 trillion by 2026, complexity grows with it. Short shelf lives, strict regulations, and ingredient variability demand technology that standard business software can’t provide.

Generic ERP systems often fail food manufacturers because they lack critical features for recipe management, lot traceability, quality control, and regulatory compliance. Many businesses resort to manual spreadsheets, creating data silos and risking costly errors. The consequences are severe: food recalls that destroy brand reputation, spoilage losses from inefficient inventory, and slow responses to supply chain disruptions.

Modern solutions like NetSuite for Food and Beverage address these challenges on a unified platform. Companies using specialized ERPs report 30% faster time-to-market and annual savings over €500K from optimized yield. The right technology, implemented correctly, transforms operations from batch tracking to recall readiness.

As a specialist in digital change and supply chain with over 15 years of experience, I’ve seen how strategic NetSuite optimization open ups the full potential of food and beverage software systems.

Important food and beverage software systems terms:

Why the Food & Beverage Industry Has Unique Software Needs

Running a food and beverage business means dealing with products that spoil, ingredients that vary, and regulations that are non-negotiable. Generic business software wasn’t designed for this reality, which is why specialized food and beverage software systems are essential.

Your inventory has expiration dates. Your ingredients have variable attributes like moisture content. Your software must handle these complexities. Furthermore, compliance with standards like the FSMA (Food Safety Modernization Act) requires meticulous, accessible records for every ingredient and production step. The regulatory compliance documentation alone justifies a specialized system.

Key operational challenges include:

- Recipe and Allergen Management: Systems must manage complex formulas, handle batch scaling, track substitutions, and prevent cross-contamination to ensure accurate labeling and consumer safety. Our article Cooking up Success with ERP in the Food and Beverage Sector explores this in detail.

- Recall Readiness: When an issue occurs, you need to trace ingredients and finished products through the supply chain in hours, not days. Your software’s ability to answer “Where did this go?” can be the difference between a contained incident and a brand-destroying crisis.

The High Cost of Inefficiency and Non-Compliance

Without the right systems, profits and reputation are at risk. Spoilage losses from poor inventory tracking eat into your bottom line. Manual errors can trigger recalls. In an industry with tight margins, eliminating inefficiency is critical for maintaining profitability. Companies using specialized software report dramatic improvements, with some saving over €500,000 annually from better yield optimization alone. Automated systems also protect your most valuable asset: customer trust and brand reputation.

Addressing Challenges for Specific Niches

The food and beverage world is diverse. A dairy processor needs to manage milk fat content and short shelf lives. A meat packer requires farm-to-table traceability. A bakery balances freshness with fluctuating demand. Fresh produce and frozen food distributors depend on unbroken cold chain management. Meanwhile, producers of organic and vegan products need to track certifications and prevent cross-contamination. Specialized software understands these nuances, unlike generic ERPs that force you to adapt your business to their limitations. We’ve seen how the right tools help these companies scale, as shown in Giving Vegan and Natural Food Companies the Tools to Grow.

Core Features & Benefits of Food and Beverage Software Systems

The power of food and beverage software systems lies in changing operational chaos into manageable, data-driven processes. With real-time visibility, your teams are synchronized, from procurement to production to quality control. This integration drives significant benefits: companies report 30% faster time-to-market, 14% faster delivery, and 10% more on-time orders. Automation frees your staff from tedious tasks to focus on innovation and growth.

For a comprehensive look, explore our guide on ERP Solutions for Food.

Understanding ERP in food and beverage software systems

At the heart of these systems is a specialized Enterprise Resource Planning (ERP) platform that acts as a single source of truth. Key capabilities include:

- Recipe and Formula Management: Manages precise measurements, processing steps, allergens, and nutritional data. It automates batch scaling and calculates costs accurately.

- Batch Production Control: Allocates materials, tracks work-in-progress, and provides full visibility into the production status of every batch.

- Quality Control Automation: Integrates testing protocols into workflows, manages Certificates of Analysis, and ensures HACCP compliance documentation is always ready.

- Cost Tracking and Yield Optimization: Provides precise data on ingredient usage versus finished product output, helping identify inefficiencies and boost profitability. Our article on Food Enterprise Resource Planning explores these capabilities in depth.

Moving to an integrated system can be transformative, taking a business from chaos to excellence in just 90 days, as detailed in A Recipe for Success: One System to Manage Your Entire Business.

Essential Lot Traceability and Recall Management

In a food safety event, speed is critical. Lot traceability is a non-negotiable feature.

- Bi-directional Traceability: Instantly trace a finished product back to its source ingredients or track a suspect ingredient forward to all affected products. This is essential for FSMA 204 compliance.

- Rapid Recall Management: Modern systems allow for mock recalls in minutes, not days. This capability allows you to precisely limit a recall’s scope, dramatically reducing its impact on your finances and brand reputation. Our insights on ERP Software for Food Industry explain this further.

Advanced Inventory and Warehouse Management

Food inventory is complex, with expiration dates and variable weights. Specialized software provides:

- FEFO (First-Expire, First-Out) Logic: Automates inventory rotation to ensure products with the earliest expiration dates are used or shipped first, reducing spoilage.

- Catch Weight Management: Tracks products sold by variable weight (e.g., meat, cheese), ensuring accurate costing and billing.

- Expiration Date Monitoring: Provides automatic alerts for products nearing their end-of-life, allowing time for proactive sales or redirection.

- Demand Forecasting & Warehouse Optimization: Uses historical data to predict needs and optimize storage, improving efficiency and service levels. Learn more about how this extends through the supply chain in our article on Food and Beverage Distribution.

Differentiating Systems: Manufacturers vs. Distributors

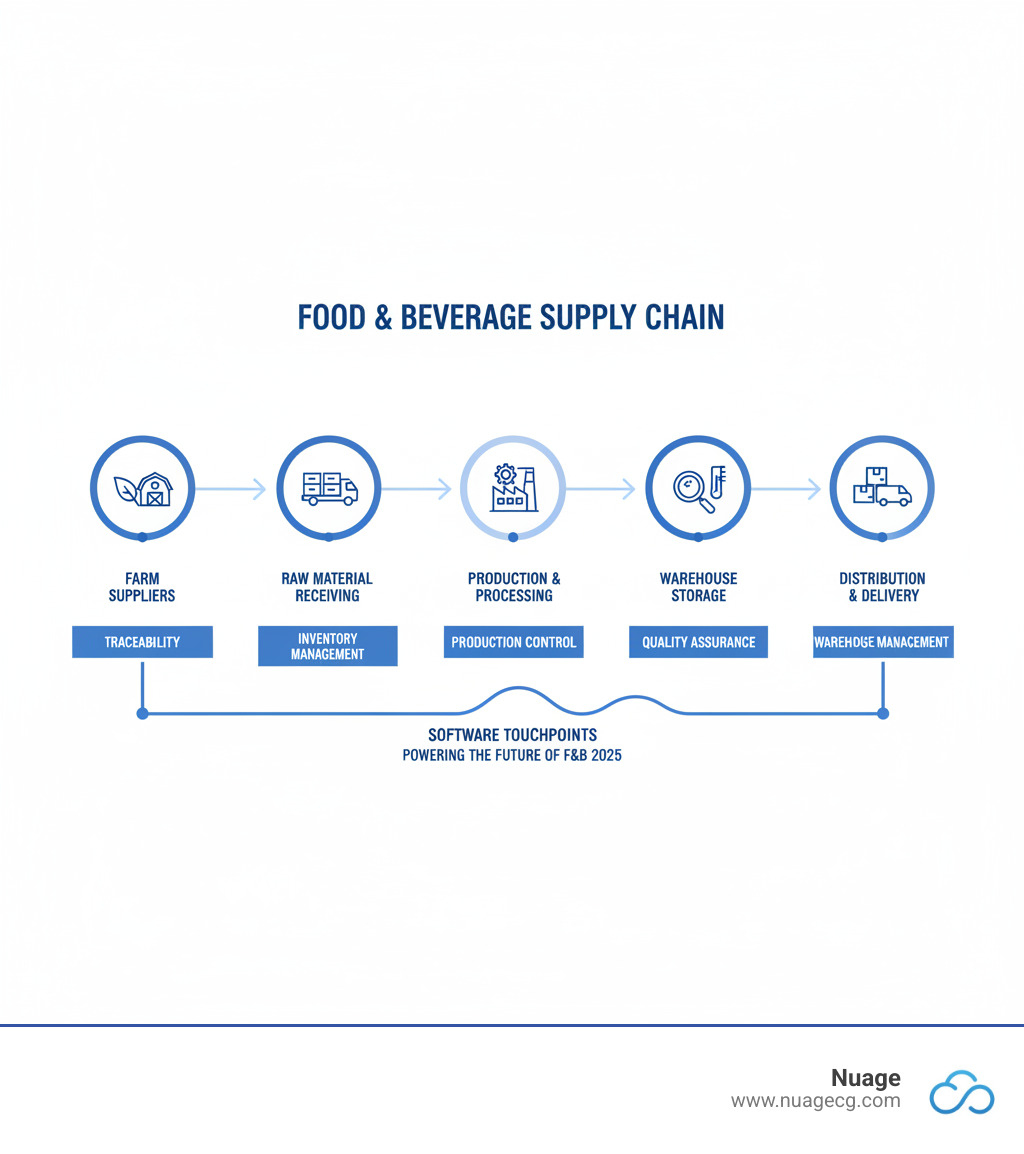

While both are part of the same ecosystem, food manufacturers and distributors have different core needs for their food and beverage software systems. Manufacturers focus on creation—changing raw ingredients into finished goods. Distributors focus on logistics—moving those goods efficiently and safely to customers.

A manufacturer’s software must excel at production, while a distributor’s must be a logistics powerhouse. These different missions demand different tools, as explored in our article on Food Manufacturing Management.

Software for Food Manufacturers

For manufacturers, the ERP is the production nerve center. Key functionalities include:

- Production Scheduling: Optimizes production runs, manages equipment capacity, and sequences batches to minimize changeovers.

- Bill of Materials (BOM) Management: Provides a detailed blueprint for each product, ensuring accurate costing, inventory planning, and consistency.

- MES (Manufacturing Execution System) Integration: Connects the shop floor to the ERP for real-time data on machine performance and labor, enabling data-driven decisions.

- Quality Assurance Workflows: Automates quality checks, manages non-conformances, and generates compliance reports.

- Yield Analysis: Compares actual vs. expected output to identify waste and optimize ingredient usage, directly impacting profitability. Our article on ERP for Food Manufacturing provides more context.

Having one system to manage the entire business can take a company like NextFoods from manual chaos to automated excellence in 90 days.

Software for Food Distributors and Retailers

For distributors, the software focus shifts to movement and fulfillment. Essential systems include:

- Warehouse Management Systems (WMS): Optimizes warehouse layouts, manages different temperature zones (frozen, refrigerated, dry), and directs picking based on FEFO logic to minimize spoilage.

- Transportation Management (TMS): Plans and optimizes delivery routes to reduce fuel costs and ensure timely, fresh deliveries.

- Direct Store Delivery (DSD): Manages mobile sales, inventory, and payment collection for drivers delivering directly to retail stores.

- Order and Trade Promotion Management: Handles the entire order lifecycle across multiple channels and manages complex pricing and promotional campaigns.

These specialized tools are covered further in our guide to Food Distribution ERP.

The Role of Digital Change and Modern Technology

Forward-thinking food and beverage companies are embracing digital change, integrating Industry 4.0 principles into their food and beverage software systems to gain a competitive edge. This means creating smart factories where machines, systems, and people communicate in real time.

Key technologies driving this change include:

- Cloud Computing: Provides scalability, remote accessibility, and reduced IT overhead, moving software from on-premise servers to the cloud.

- Industrial Internet of Things (IIoT): Uses sensors to collect real-time data from machinery and the environment, feeding it into your ERP for analysis and action.

- Artificial Intelligence (AI) and Machine Learning: Analyzes vast datasets to predict equipment failures, optimize schedules, and forecast demand with incredible accuracy.

Our insights on Food Industry Digital Transformation explore how these technologies work together. Platforms like NetSuite’s cloud ERP bring these tools together to drive innovation.

How IIoT and Automation Drive Efficiency

IIoT turns data into action. Real-time monitoring of processes like Clean-in-Place (CIP) operations can reduce water consumption by up to 45%. Predictive maintenance uses sensor data to forecast equipment failures, allowing for repairs during planned downtime and preventing costly production stops. Automated cleaning reports for CIP can reduce management time by 20%, saving $20,000-$40,000 annually by eliminating manual data entry. This visibility directly improves Overall Equipment Effectiveness (OEE) by identifying bottlenecks and quality issues. Learn more about these improvements in our article on Digital Transformation Food.

The Power of Cloud-Based ERP

A cloud-based ERP like NetSuite for Food and Beverage offers strategic advantages that are essential for growth.

- Scalability: The system grows with your business without requiring new hardware.

- Accessibility: Secure access for your team from anywhere, on any device.

- Automatic Updates: You always have the latest features and security patches without IT intervention.

- Reduced IT Overhead: Eliminates the cost and complexity of maintaining on-premise servers.

- Improved Data Security: Reputable cloud providers offer enterprise-grade security and data protection.

A unified cloud ERP provides a complete, real-time view of your business, eliminating data silos. Our customer story about Alpha Foods choosing us to implement NetSuite ERP shows how this approach streamlines operations.

How to Select the Right System & Future Outlook

Choosing the right food and beverage software system is a critical business decision. It’s about finding a technology partner that understands your industry and can support your growth. Rushing the decision based on price or a flashy demo often leads to a poor fit.

Start by evaluating your specific pain points, whether it’s recall readiness, spoilage, or spreadsheet chaos. When selecting a system and an implementation partner, consider these critical factors:

- Scalability for Growth: Will the system support you in five years? Ensure it can handle more users, locations, and transactions.

- Integration Capabilities: The ERP must connect seamlessly with other systems (MES, WMS) to eliminate manual data entry.

- Total Cost of Ownership (TCO): Look beyond the initial price to include implementation, training, and support. Cloud solutions often have a lower TCO.

- Vendor Expertise: Your partner must understand food and beverage nuances like FSMA 204 and catch weights. At Nuage, we have over 20 years of experience helping F&B companies steer these challenges.

- Implementation Support: A great system is worthless without proper implementation. Look for a partner with a proven methodology and comprehensive support.

Our guide on ERP for Food and Beverage Industry breaks down what to expect.

Contributing to Sustainability and ESG Goals

Modern software is a powerful tool for achieving sustainability goals. It provides waste reduction tracking, energy consumption monitoring, and automated carbon footprint reporting. It can also help manage ethical sourcing by tracking supplier certifications and support sustainable packaging initiatives by monitoring material usage and recycled content.

Future Trends in food and beverage software systems

The technology continues to evolve. Keep an eye on these future trends:

- Blockchain for Traceability: Offers an immutable, transparent record of a product’s journey, creating unprecedented trust in food safety.

- Advanced AI for Forecasting: Will use external data like weather and social media trends for hyper-accurate demand prediction, minimizing waste.

- Hyper-automation: Combines AI and RPA to automate entire end-to-end workflows with minimal human intervention.

- Connected Worker Platforms: Empowers frontline employees with mobile tools and AR, boosting productivity and safety while reducing training time.

Conclusion

The modern food and beverage industry runs on technology. Generic software fails to address the unique complexities of recipe management, lot traceability, and regulatory compliance. A specialized food and beverage software system is no longer optional—it’s a core driver of safety, efficiency, and competitive advantage.

The right system provides real-time visibility, automates critical processes, and protects your brand. As technology evolves with AI, blockchain, and IIoT, having a scalable platform is essential for future success.

However, technology alone is not the answer. You need a partner who understands both the software and your specific business challenges. That’s where we come in.

At Nuage, we are your NetSuite Optimization Engine. With over 20 years of experience in digital change, we help food and beverage companies select, implement, and support the right solution. We don’t just sell software; we partner with you to solve your biggest challenges, from reducing waste to scaling for growth.

Ready to transform your operations from spreadsheet chaos to automated excellence? Let’s find what’s possible when you have the right technology and the right partner.

Transform your business with NetSuite