Why Digital Change Food Processing is Critical for Modern Business

Digital change food processing is reshaping how companies operate, from farm to fork. By integrating technologies like ERP systems, AI, IoT, and blockchain, businesses are opening up major benefits: improved efficiency, improved food safety, greater supply chain transparency, and increased sustainability.

Today’s food and beverage industry is in rapid transition. Connected sensors monitor processes in real time, algorithms forecast price fluctuations, and consumers scan products to view their farm-to-shelf journey. Global demand for roasted coffee grew by 31% between 2020 and 2024, yet many businesses are held back by legacy systems, creating inefficiencies that modern competitors exploit.

Mounting pressures from consumer demands for transparency, tighter regulations from the FDA and GFSI, and persistent supply chain disruptions are forcing companies to adapt. For businesses using NetSuite but not reaching its full potential, this presents a significant opportunity. Most companies only use 20% of their ERP’s capabilities, leaving huge efficiency gains untapped.

I’m Louis Balla, CRO and partner at Nuage. With over 15 years of experience helping food and beverage companies optimize their digital change food initiatives, I’ve seen how the right technology strategy, centered on NetSuite and key integrations, can revolutionize operations.

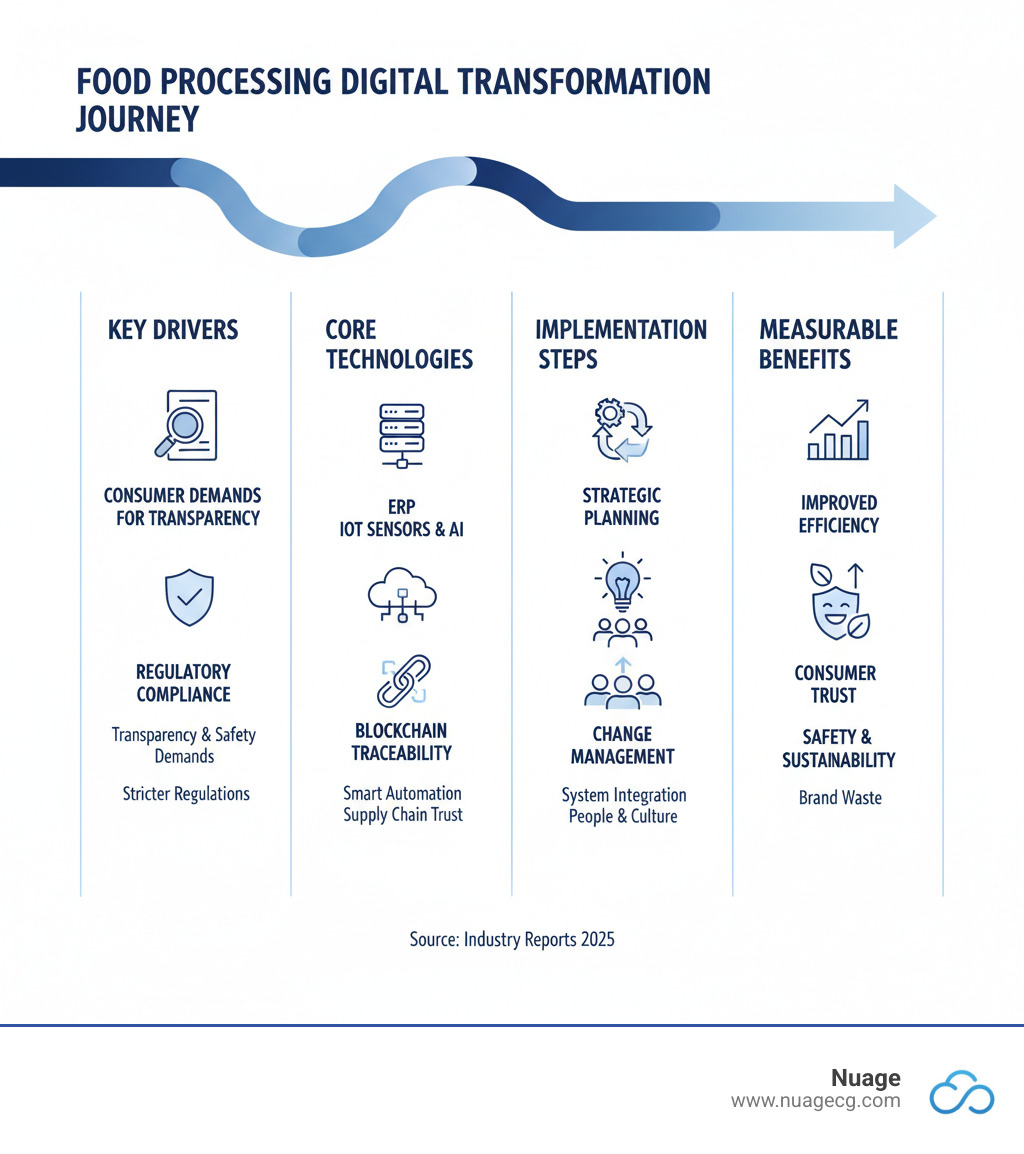

The ‘Why’: Key Drivers Pushing the Food Industry Towards Digital Change

The food and beverage industry is at a tipping point. While other sectors acceptd technology decades ago, many food companies are still using outdated processes. This is no longer sustainable.

Events like the romaine lettuce E. coli outbreaks served as a wake-up call, as the outbreaks highlighted critical traceability gaps in fragmented supply chains. Simultaneously, consumer demands for transparency, stricter regulations from the FDA and GFSI, supply chain disruptions, and pressure for sustainability are creating a perfect storm for change. Companies that don’t adapt are being left behind, especially as global demand for products like roasted coffee grew 31% from 2020-2024. Digital change food processing is now essential for survival.

Evolving Consumer Expectations

Today’s consumers expect instant information and personalization. They use QR codes to trace a product’s origin, verify ethical sourcing, and check ingredients to support their health consciousness. The demand for convenience has also exploded, with on-demand delivery becoming a standard expectation. Companies unable to provide real-time inventory data and seamless digital experiences are losing customers. This demand for transparency is only growing stronger.

Mounting Regulatory and Supply Chain Pressures

The regulatory landscape is increasingly complex, with mandates like the Food Safety Modernization Act (FSMA) and standards from the Global Food Safety Initiative (GFSI) requiring detailed records and rapid recall capabilities. Relying on outdated legacy systems for this introduces risks like compliance failures, high costs from manual data entry, and slow response times.

Supply chain disruptions and inflation have become the new normal, squeezing margins and demanding greater operational efficiency. Reducing food waste through better forecasting is now critical for profitability. Thriving companies use integrated systems like NetSuite to gain the supply chain resilience needed to steer these challenges. As market competition intensifies from digital-native brands, modernizing operations is no longer optional.

The ‘What’: Core Technologies Reshaping Food & Beverage Operations

The digital change food industry is experiencing is a fundamental reimagining of operations, powered by a suite of integrated technologies. This revolution is driven by ERP systems, Artificial Intelligence (AI), the Internet of Things (IoT), blockchain, and automation, all supported by scalable cloud computing.

These technologies work in concert: IoT sensors collect data, an ERP system processes it, AI analyzes it for insights, and automation acts on those insights in real time. This synergy is creating smarter, more resilient food supply chains.

ERP Systems: The Digital Backbone of F&B

An ERP system is the nervous system of a modern food business. It creates a centralized data hub that eliminates information silos and enables process automation for repetitive tasks. For food companies, this is critical for real-time inventory management of perishable goods, consistent recipe and formulation management, and streamlined financial management.

We recommend NetSuite for Food and Beverage due to its industry-specific features and scalability. As a cloud-based ERP, it handles seasonal spikes without massive infrastructure costs and allows for faster implementation. If you’re new to ERP, you can learn the fundamentals with our NetSuite 101 guide.

EMBEDDED VIDEO: NetSuite for Food and Beverage Overview

AI, IoT, and Automation: The Smart Layer

While an ERP provides the foundation, AI, IoT, and automation create the intelligence layer. AI-powered predictive analytics improves demand forecasting to reduce waste and stockouts. Smart sensors (IoT) monitor equipment and environmental conditions, enabling predictive maintenance to prevent costly downtime.

In production, automated quality control uses computer vision for consistent inspection, while robotics in processing handles repetitive tasks, improving efficiency and safety. This smart layer also extends to customer relations. Salesforce integration helps manage customer data, and our expertise in connecting CRM and ERP systems ensures all your systems work together seamlessly.

Blockchain and Big Data: Ensuring Trust and Transparency

Trust is paramount in the food industry. Blockchain technology provides farm-to-fork traceability with tamper-proof records, which is becoming essential for food fraud prevention. When a consumer scans a QR code, they can see a product’s entire journey, building consumer trust.

When combined with big data insights from IoT and ERP systems, companies can uncover patterns to improve quality and efficiency. This level of transparency is reshaping the industry’s approach to accountability, as highlighted in research on blockchain applications in the agri-food sector.

The ‘How’: A Strategic Roadmap for Successful Digital Change Food Initiatives

A digital change food journey can feel overwhelming, but a clear roadmap makes it manageable. Success comes from a methodical approach built on strategic planning, phased implementation, and effective change management.

This process also requires robust cybersecurity and continuous ROI measurement to ensure your investments deliver real value. It’s about building a solid foundation before adding advanced features.

Step 1: Define Clear Objectives & Address Key Challenges

Before adopting new technology, ask: what problem are you trying to solve? Setting goals requires clarity. Are you targeting improved operational efficiency, improved food safety, or increased sustainability? Make goals specific and measurable, such as, “Reduce food waste by 25% within 12 months.”

Next, start identifying pain points. Is it manual data entry, a lack of real-time visibility, or high spoilage rates? Honesty here is crucial.

Finally, plan for overcoming barriers. Common challenges include cost constraints, a skills gap, resistance to change, and outdated legacy systems. Investing in cloud solutions to lower upfront costs makes digital change more accessible, while a clear strategy can address the other problems. Addressing these issues head-on is key to a successful implementation.

Step 2: Invest in Scalable Solutions and Foster a Digital Culture

Your digital solutions must be able to keep pace with a fast-moving market. Scalable technology is essential for survival. Cloud infrastructure provides the flexibility to handle demand spikes and business growth without breaking.

Technology is only as good as the people who use it. Employee training is critical for adoption and ensuring your team understands how new tools make their jobs easier. This effort must be supported by leadership buy-in; when executives champion the change, success rates skyrocket.

Fostering innovation by encouraging feedback from frontline workers provides invaluable insights. Finally, a culture of continuous learning keeps your organization ahead of the curve in a constantly evolving digital landscape.

At Nuage, we’ve seen this approach transform companies. With over 20 years in digital change, our experienced team helps guide both the technological and cultural shifts necessary for success.

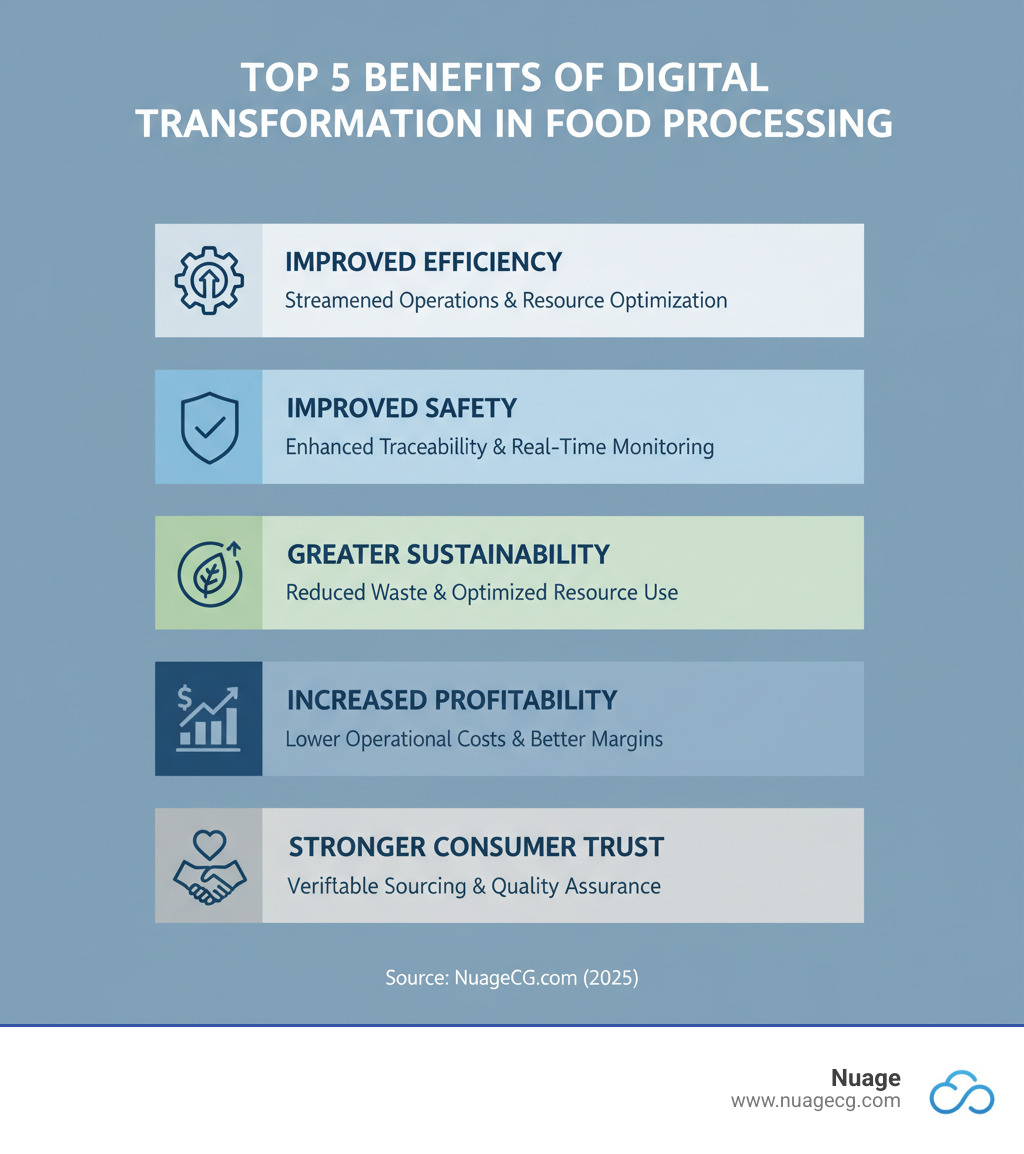

The Payoff: Tangible Benefits of Digitizing the Food Supply Chain

What are the tangible benefits of a digital change food initiative? The rewards are substantial, touching every aspect of the business, from production to customer trust.

The journey pays off in key areas: improved efficiency, improved safety, greater sustainability, increased profitability, and stronger consumer trust.

Consider Lavazza, the iconic coffee company. Facing a 31% surge in global demand, they undertook a comprehensive digital modernization of a flagship facility. By partnering with technology experts, they completed the project in half the expected time with zero production downtime. The results—greater control, improved energy efficiency, and more agile systems—demonstrate what’s possible with a committed digital strategy. We see similar changes regularly; read our customer success stories for more examples.

Improved Efficiency and Profitability

Digital tools have an immediate impact on the bottom line. Reduced downtime is a major win, as predictive maintenance anticipates equipment failures before they happen. Optimized production schedules, driven by AI forecasting, ensure you produce what’s needed, reducing waste and stockouts. Automation leads to lower labor costs by handling repetitive tasks, freeing employees for higher-value work. Systematic waste reduction across the supply chain directly strengthens profit margins.

Improved Safety, Transparency, and Sustainability

Digital initiatives also deliver remarkable improvements in safety and environmental responsibility. Real-time monitoring with IoT sensors tracks critical parameters, ensuring product integrity. Instant recall capability, powered by ERP systems like NetSuite, transforms a potential crisis into a manageable event, reducing a process that took weeks to mere hours.

Digital platforms enable ethical sourcing verification, providing the data to prove your commitments. This transparency, combined with optimized logistics and resource management, leads to a reduced carbon footprint and significant water and energy savings. These changes support a circular agri-food system that minimizes waste and maximizes efficiency.

Frequently Asked Questions about Digital Change in Food

Here are answers to common questions about starting a digital change food processing journey.

What are the first steps for a small F&B business to start digital change?

Starting small is the smartest approach. Begin by identifying your biggest pain point, such as inefficient inventory management or manual order processing. Focus on scalable, cloud-based solutions that can grow with your business. For example, NetSuite’s cloud-based platform allows you to start with core modules and add functionality as you expand. The key is to pick one key process, master it, then expand. This avoids overwhelm and builds momentum for future projects.

How does digital change contribute to food sustainability?

Digital change food initiatives are game-changers for sustainability. They enable precision agriculture to reduce water and resource use. Smart supply chains optimize logistics routes, cutting fuel consumption and spoilage. In facilities, IoT sensors and AI optimize energy use, while data analytics helps track and manage your entire environmental footprint. This drives continuous improvement toward a more circular agri-food system.

What is the role of an ERP in the digital change food journey?

An ERP system like NetSuite acts as the central nervous system of your business. It integrates data from every department—procurement, production, sales, finance—into a single source of truth. This is essential for making informed, rapid decisions. Without a solid ERP foundation, other digital efforts become fragmented. An ERP provides the reliable backbone that allows advanced technologies like AI and IoT to deliver their full value. Getting your ERP right first is the platform that makes everything else more powerful.

Conclusion: Your Next Course in Digital Excellence

The journey of digital change food processing is happening now. Delaying these changes means handing competitors a head start in efficiency, safety, and sustainable growth. This change doesn’t have to be overwhelming. By strategically integrating technologies like NetSuite ERP, AI, and IoT, you build a foundation for a resilient, transparent, and profitable operation.

Manual processes create invisible costs through inventory errors, compliance headaches, and preventable recalls. Digital change food technologies plug these profit drains, freeing your team to focus on innovation and customer relationships.

As a NetSuite Optimization team with over 20 years of experience, we know the right approach makes all the difference. We don’t just implement software; we partner with you to steer your digital journey, ensuring technology serves your unique needs.

The food industry waits for no one. Consumer expectations are rising, regulations are tightening, and supply chains are growing more complex. You don’t have to steer this alone.

Ready to transform your operations? Explore our NetSuite solutions and find how the right optimization partner can turn your digital challenges into your greatest competitive advantages.