Why Advanced Manufacturing Matters More Than Ever

NetSuite advanced manufacturing replaces disconnected systems with a unified cloud platform, integrating shop floor control with financial reporting. It extends NetSuite’s core routing into the Advanced Manufacturing Work Bench, allowing manufacturers to define work instructions, manage materials, and capture real-time shop floor data for planned production schedules.

Key capabilities include:

- Unified production control from order-to-cash

- Advanced planning with finite capacity scheduling

- Mobile shop floor control with barcode scanning

- Integrated quality management and lot tracking

- Support for discrete, assembly, and batch manufacturing

- Manufacturing Execution System (MES) visibility

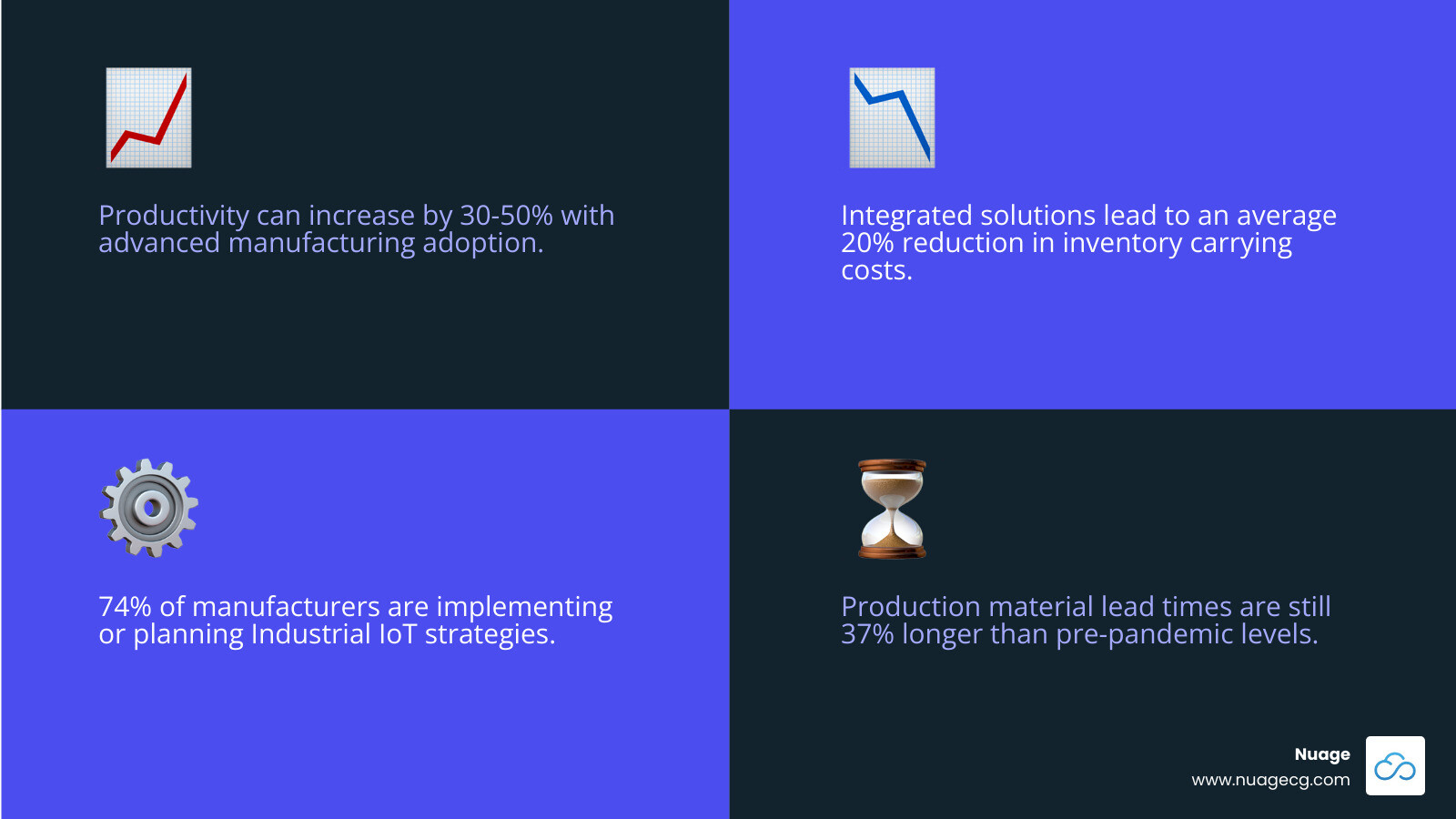

Adopting this approach can improve productivity by 30-50% and reduce inventory carrying costs by 20%. As lead times remain 37% longer than pre-pandemic levels, such efficiencies are critical. While 74% of manufacturers are pursuing an Industrial IoT (IIoT) strategy, 56% face cultural and structural barriers to smart factory implementation, highlighting the need for a strategic approach.

I’m Louis Balla, CRO and partner at Nuage. With over 15 years of experience in digital change and supply chain optimization, I’ve helped manufacturers leverage NetSuite advanced manufacturing to streamline operations and drive growth.

What is NetSuite Advanced Manufacturing and How Does It Evolve Production?

Many manufacturing operations suffer from disconnected systems, where sales, production, and accounting all use different software. NetSuite advanced manufacturing eliminates this chaos by bringing all operations into a single, unified cloud solution. It creates a single source of truth for the entire process, from customer order to final shipment.

This is achieved through Plant to Enterprise (P2E) integration, where shop floor data flows seamlessly to executive dashboards in real-time. Critical decisions are based on current information, not yesterday’s numbers. NetSuite advanced manufacturing builds on the robust foundation of NetSuite ERP, extending its capabilities to handle complex production scenarios and scale with your business.

Want to see this change in action? This Introducing Advanced Manufacturing Video walks you through how NetSuite reimagines manufacturing operations.

From Traditional Methods to a Smart Factory Approach

Traditional manufacturing often relies on linear processes, manual tracking with spreadsheets, and siloed data, making it difficult to get a complete operational picture. This leads to a reactive approach, where problems like machine breakdowns or quality issues are addressed only after they occur.

NetSuite advanced manufacturing flips this model by introducing data-driven workflows that adapt in real-time. Manual tracking is replaced by automated data capture, and information silos are broken down to provide integrated visibility. This shifts operations from reactive to predictive, warning you about potential issues before they happen. The result is typically reduced lead times and improved resource utilization, boosting productivity by 30% to 50%.

Core Functionalities of NetSuite Advanced Manufacturing

NetSuite advanced manufacturing provides complete control over your operations:

- Order-to-Cash and Build-to-Ship: Connects sales directly to production, managing the entire lifecycle from raw materials to finished goods.

- Advanced Planning and Scheduling (APS): Goes beyond basic scheduling by considering actual capacity constraints to create realistic production plans.

- Manufacturing Execution System (MES): Delivers real-time shop floor control, tracking work orders, material issuance, machine downtime, and labor hours.

- Quality Management: Integrates qualitative and quantitative inspections, test specifications, and non-conformance management into the production process.

- Variance Management: Compares actual manufacturing costs against standard costs to identify areas for process optimization and cost reduction.

Industries That Benefit Most

NetSuite advanced manufacturing is highly adaptable to various production styles. Discrete and assembly manufacturing companies (e.g., electronics, machinery) benefit from advanced Bills of Material (BOMs) and detailed routing. Batch and process manufacturing businesses (e.g., food and beverage, chemicals) gain tools for formulas, recipes, lot traceability, and co-product management.

Key industries include:

- Medical Devices: Stringent quality control and detailed lot tracking for regulatory compliance.

- Electronics: Real-time inventory and production planning for rapid product cycles.

- Automotive: Precise production scheduling and quality control for parts suppliers and assemblers.

- Food and Beverage: Meticulous lot traceability and expiration date management for safety.

The core benefits of real-time visibility and optimized production apply across all sectors. See how companies have transformed their operations in our Customer Stories.

Choosing Your Path: NetSuite Manufacturing Modules Compared

NetSuite offers three distinct manufacturing modules, allowing you to choose a solution that matches your current complexity and scale as your business grows. This tiered approach ensures you can start where you are and evolve without painful migrations.

This flexibility makes NetSuite a powerful long-term partner. To dive deeper, this guide offers valuable insights: Solving Manufacturing Complexity with NetSuite.

Level 1: Work Orders & Assemblies

This foundational module is ideal for light assembly and basic production, such as combining components into finished kits. It focuses on what goes in and what comes out, without tracking the detailed production process. The backflushing feature automatically deducts component inventory upon assembly completion, perfect for make-to-stock environments. This module does not include WIP tracking, keeping it simple for straightforward operations.

Level 2: WIP & Routings

For growing manufacturers, this module introduces greater shop floor control. Key features include:

- Work Centers: Define specific locations or machines to plan resources and identify bottlenecks.

- Labor Costing: Track and allocate actual labor costs to jobs for a clearer picture of profitability.

- Routing Definition: Map out the sequence of operations, specifying work centers and time required.

- WIP Tracking: Gain financial control by monitoring the value of partially completed items as they move through production.

This module uses infinite capacity scheduling and provides a Gantt chart view for a visual timeline of production.

Level 3: Advanced Manufacturing

This is the complete NetSuite advanced manufacturing solution, offering total control and efficiency. It includes all features from the previous levels, plus powerful additions:

- Finite Capacity Scheduling: Plans production based on the real-world availability of machines and labor, creating achievable schedules.

- Batch Management: Supports process manufacturers with tools for formulas, recipes, co-products, and alternate assets.

- MES Capabilities: Brings real-time data capture to the shop floor for work order tracking, material issuance, and downtime reporting via mobile devices.

| Feature | Work Orders & Assemblies | WIP & Routings | Advanced Manufacturing |

|---|---|---|---|

| Basic Assembly | Yes | Yes | Yes |

| BOM Management | Yes | Yes | Yes (Advanced BOM) |

| Work Center Management | No | Yes | Yes |

| Labor Costing | No | Yes | Yes |

| WIP Tracking | No | Yes | Yes |

| Gantt Chart View | No | Yes | Yes |

| Finite Capacity Scheduling | No | No | Yes |

| Batch Management | No | No | Yes |

| MES Capabilities | No | No | Yes |

| Mobile Shop Floor Control | No | No | Yes |

| Quality Management | No | No | Yes |

Advanced Manufacturing is the single source of truth for optimizing operations, reducing costs, and accelerating time to value.

A Closer Look: Key Features and Technologies

Let’s explore the specific features that give NetSuite advanced manufacturing its power. These tools are designed to transform production control, data capture, and operational insight. For deep technical details, refer to the NetSuite Applications Suite Documentation.

The Manufacturing Work Bench and Scheduler

The Manufacturing Work Bench is the mission control for production. Its standout feature is finite production scheduling, which creates realistic schedules by considering actual machine capacity and labor availability. This avoids over-promising and scrambling to meet unrealistic deadlines.

Rough-cut capacity planning (RCCP) provides a high-level view to spot potential bottlenecks or idle resources in advance. The user-friendly drag-and-drop scheduling interface allows for quick adjustments to the production plan, with the system automatically showing the impact of any changes. It helps balance resource supply versus demand and uses dynamic schedule codes to manage different priorities.

Mobile Capabilities and Shop Floor Control

NetSuite advanced manufacturing brings real-time data capture to the factory floor via tablets and handheld devices, eliminating manual entry.

With barcode scanning, workers can instantly update inventory and production status for materials, work orders, and finished goods, often improving inventory accuracy to over 98%. Key functions include real-time work order completion, precise material issuance tracking, instant downtime reporting, and effortless labor tracking. Solutions like RF-SMART Mobile Solutions integrate seamlessly with NetSuite to provide this connectivity, with user training typically taking less than two hours.

Quality Management and Traceability

Quality control is woven directly into the production process. You can define inspections with specific test requirements and pass-fail criteria that trigger automatically at key production stages. Lot and serial tracking provides a complete history of every component and finished product, which is invaluable for regulatory compliance in industries like medical devices or food and beverage.

When issues arise, non-conformance reporting offers a structured workflow to resolve problems quickly. Vendor Return Authorizations (VRAs) streamline the return of defective materials to suppliers. This comprehensive approach to compliance creates detailed audit trails and maintains high quality standards with minimal administrative overhead.

Implementation and Best Practices

Successfully implementing NetSuite advanced manufacturing requires a solid foundation, careful planning, and the right team. It’s a change to your entire organization’s operations, making a phased approach with thorough data migration, user training, and change management essential.

At Nuage, we guide manufacturers through this journey, acting as a strategic partner to find the right solutions for your unique challenges. A NetSuite Assessment is a smart first step to map out your current and future state.

Prerequisites for Implementing NetSuite Advanced Manufacturing

Before implementation, several building blocks must be in place:

- Setup: An active NetSuite account with the Advanced Manufacturing SuiteApp installed and core manufacturing features enabled and configured.

- Work Centers: Both NetSuite Work Centers and Advanced Manufacturing Work Centers must be set up with a 1-to-1 mapping and identical names.

- BOM Configuration: Bills of Material must be accurately configured, especially for features like component yield.

- Partner Involvement: The complexity of NetSuite advanced manufacturing makes an experienced partner essential for proper configuration, customizations (like XML-based traveler templates), and technical guidance. Our team can also walk you through NetSuite Pricing to ensure a clear understanding of the investment.

Best Practices for Operational Excellence

Once live, these practices will drive exceptional performance:

- Align operation sequence dates between NetSuite and Advanced Manufacturing for reliable backward scheduling.

- Use forward scheduling strategically for operations involving concurrent batching.

- Proactively manage inactive BOM items by removing them before creating new work orders.

- Leverage mobile data capture for real-time data that dramatically reduces errors and informs performance reports.

- Regularly review performance reports to spot trends and identify improvement opportunities.

- Compare actual vs. standard costs through variance management to pinpoint inefficiencies.

- Increase script yield limits (typically to 500) in the script deployment record to prevent timeout errors during traveler generation.

Addressing Common Challenges and Limitations

Knowing what to expect can help manage common challenges:

- Script Timeouts: The Advanced Manufacturing tablet can display a maximum of 45 operations. Complex work orders may need to be broken down.

- Traveler Customization: Customizing traveler templates often requires XML experience, an area where a partner can provide significant help.

- Employee Permissions: Ensure employees have at least “View” access to an employee record to use Advanced Manufacturing functionalities.

- Organizational Resistance: About 56% of organizations cite cultural challenges as a primary barrier to smart factory implementation. Strong change management, clear communication, and comprehensive training are key to fostering adoption.

A skilled implementation partner like Nuage can help anticipate and steer these challenges, ensuring a smoother implementation and a better return on your investment.

Frequently Asked Questions about NetSuite Advanced Manufacturing

Manufacturers often ask how NetSuite advanced manufacturing will work in their specific environment. Here are answers to the three most common questions.

How does Advanced Manufacturing handle different production types like discrete and batch?

NetSuite advanced manufacturing adapts to different production philosophies within a single platform.

-

For discrete and assembly manufacturers (e.g., electronics, machinery), it provides improved operations routings, configurable work order completion logic, and detailed planning parameters for managing complex Bills of Material and precise assembly.

-

For batch or process manufacturers (e.g., food and beverage, chemicals), it adds specialized capabilities like recipe and formulation management, alternate assets, co-products, and FIFO material issuance. Barcode-enabled batch travelers automatically generate lot IDs for full traceability, which is critical in regulated industries.

Can NetSuite Advanced Manufacturing integrate with other systems?

Yes, integration is a core strength. As part of the unified NetSuite platform, it connects seamlessly with financials, CRM, and inventory management, creating a smooth order-to-cash workflow.

Furthermore, the SuiteCloud platform allows for connections to specialized third-party systems. Using APIs, you can integrate with PLM software for engineering specs, SCADA systems for machine data, or IoT devices for real-time monitoring. NetSuite acts as the central nervous system, creating a single version of the truth across all critical systems.

What is the difference between infinite and finite capacity scheduling?

The difference is fundamental to effective production planning.

-

Infinite capacity scheduling, found in NetSuite’s WIP & Routings module, plans production without considering resource constraints. It assumes unlimited capacity, which can lead to unrealistic schedules and missed deadlines.

-

Finite capacity scheduling, a key feature of NetSuite advanced manufacturing, plans production based on the actual, limited availability of your machines and labor. It respects real-world constraints to create achievable schedules.

Finite scheduling helps identify bottlenecks, optimize resource use, and improve on-time delivery. It moves planning from wishful thinking to reality, which is essential for any complex manufacturing environment.

Transform Your Factory Floor with Expert Guidance

NetSuite advanced manufacturing offers a fundamental shift in operations, changing disconnected systems into an integrated powerhouse. It delivers improved efficiency through finite capacity scheduling, real-time visibility into every work order, and improved control over the entire production process. This unified system creates a direct link from your plant floor to your enterprise operations (P2E integration).

At Nuage, our two decades of experience in digital change have taught us that success depends on partnership. We work alongside you to understand your unique challenges, whether in discrete or batch manufacturing, and help you select, implement, and support an ERP solution that truly fits your business.

The journey to advanced manufacturing can be complex, which is why partnering for success is so critical. Our team has the expertise to steer technical nuances and manage the change required for a successful implementation.

Ready to take the next step? Speak to an Expert to discuss your specific challenges. You can also explore our comprehensive NetSuite solutions to see how we’ve helped other manufacturers transform their operations. Every great change starts with a conversation, and we’re here to guide you through the entire process.

Last Updated: January 3, 2026

Looking for help optimizing your NetSuite? Contact our team for a free consultation.