Why Food Manufacturing Management Has Never Been More Critical

Food manufacturing management is the comprehensive oversight of production processes, quality control, regulatory compliance, and operational efficiency in food and beverage operations. Here’s what it covers:

- Production Planning: Recipe development, batch scheduling, and resource allocation

- Quality Systems: HACCP implementation, GMP compliance, and traceability protocols

- Regulatory Compliance: FDA, USDA, and international food safety standards

- Supply Chain Control: Ingredient sourcing, inventory management, and distribution

- Technology Integration: ERP systems, MES platforms, and IoT monitoring

- Financial Management: Cost control, margin analysis, and performance tracking

The food manufacturing industry is experiencing unprecedented growth, with global revenue projected to reach $10.07 trillion in 2024 and a steady annual growth rate of 6.53%. Yet this expansion brings intense challenges.

Modern consumers demand transparency, safety, and sustainability. Regulatory pressures are at an all-time high. Supply chain disruptions have become the new normal. Rising costs are eating into already thin margins while poor operational visibility slows critical decision-making.

As one industry expert put it: “Food manufacturing has become a logistical and compliance nightmare for many producers.” The complexity of multi-line production, manual data entry errors, and equipment downtime creates a perfect storm of inefficiency.

The solution lies in structured, technology-enabled management systems. Companies that implement comprehensive NetSuite ERP solutions see dramatic improvements – like the lamb processor that achieved a 35% boost in traceability and 25% reduction in production planning time.

Small food manufacturers have unique opportunities to launch innovative products in niche markets, but only if they can manage the chaos of modern food production. The shift from spreadsheets to integrated systems isn’t optional anymore – it’s survival.

I’m Louis Balla, and I’ve spent over 15 years helping food manufacturers transform their operations through digital solutions and supply chain optimization. My experience in food manufacturing management shows that the companies thriving today are those that accept structured processes, technology integration, and continuous improvement from day one.

Why This Guide Matters

The opportunity in food manufacturing has never been larger. With the 6.53% compound annual growth rate, we’re seeing unprecedented expansion across all segments. The Confectionery & Snacks segment alone represents $1.77 trillion in global volume, while online sales are expected to contribute 4.3% of total revenue by 2024.

But here’s what excites us most: small food manufacturers have unique opportunities to launch innovative products that cater to niche markets in this busy food landscape. Every established food brand started small, proving that scale can follow quality and strategy.

The challenge? Navigating the complexity of modern food production while maintaining the agility that gives smaller operations their competitive edge. This guide will show you how to build systems that scale from startup to enterprise without losing control of your operations.

Mastering Food Manufacturing Management Fundamentals

The foundation of successful food manufacturing management starts long before your first production run. We’ve seen too many promising food businesses stumble because they rushed into production without proper groundwork. Let’s build your operation the right way.

Conducting Market & Competitor Analysis

Before you develop your first recipe, you need to understand your market landscape. We recommend starting with detailed customer personas – not just demographics, but psychographics. What drives your target customers’ purchasing decisions? What gaps exist in current offerings?

The direct-to-consumer (DTC) growth trend creates exceptional opportunities for small manufacturers. Unlike traditional retail distribution, DTC allows you to build direct relationships with customers, gather immediate feedback, and maintain higher margins. This shift has opened doors that were previously locked for smaller players.

In the $1.77 trillion confectionery and snacks market, there’s room for innovation. We’ve worked with clients who found success by identifying underserved dietary needs, regional flavor preferences, or sustainable packaging solutions that larger manufacturers couldn’t address quickly.

Your competitive analysis should extend beyond direct competitors. Study companies that serve similar customer needs, even if they’re in different categories. A successful artisanal bakery might offer insights for a specialty sauce manufacturer about customer engagement and brand storytelling.

Building a Bank-Ready Business Plan

Your business plan is more than a document – it’s your operational roadmap. We’ve reviewed hundreds of food manufacturing business plans, and the successful ones share common elements:

Capital budgeting that accounts for the reality of food production. Equipment costs, facility modifications, and working capital requirements are typically higher than initial estimates. Plan for 20-30% contingency on your capital budget.

Cash flow modeling that reflects the seasonality and payment terms common in food manufacturing. Retailers often have 30-60 day payment terms, while your ingredient suppliers may require faster payment. This timing mismatch can create cash flow challenges if not properly planned.

Break-even analysis that includes all true costs of production. Many new manufacturers underestimate the cost of compliance, quality control, and waste. Include these factors in your pricing model from the beginning.

Navigating Legal & Regulatory Problems

Food manufacturing is one of the most heavily regulated industries worldwide. The complexity can be overwhelming, but systematic compliance is non-negotiable. Every year, countless cases of foodborne illness occur due to contaminated products, making regulatory compliance both a legal requirement and a moral imperative.

Food safety certificates form the backbone of your compliance program. In the US, you’ll need to comply with FDA and USDA regulations depending on your product category. The FDA Food Code provides comprehensive guidelines for food safety practices, while FSMA (Food Safety Modernization Act) requires preventive controls and traceability.

For international operations, FSSAI licenses are required in India, along with optional certifications like BIS or Agmark. European operations must comply with EU food safety regulations, which often exceed US requirements.

Recall preparedness isn’t optional – it’s when, not if, you’ll need these procedures. Develop and test your recall procedures before production begins. This includes lot coding systems, customer notification procedures, and product retrieval processes.

Organic and kosher certifications can open premium market segments but require ongoing compliance monitoring. ISO 22000 certification demonstrates your commitment to food safety management systems and can be a competitive advantage in B2B sales.

For comprehensive guidance on regulatory compliance, we recommend reviewing scientific research on food safety regulations to understand the latest developments in food safety standards.

Essential Licenses & Insurance

Beyond basic business licenses, food manufacturers need specialized coverage. Product liability insurance protects against claims related to foodborne illness or product defects. Contamination coverage is essential for managing the costs of product recalls, facility cleaning, and business interruption.

Professional liability coverage for food manufacturers should include coverage for regulatory violations, as fines and legal costs can be substantial. Consider cyber liability insurance as well, especially if you’re collecting customer data through DTC sales channels.

Designing the Production Engine: From Recipe to Dispatch

The heart of food manufacturing management lies in your production system. This isn’t just about making food – it’s about creating a repeatable, scalable, and compliant manufacturing process that delivers consistent quality while maintaining profitability.

Good Manufacturing Practices (GMP) in Action

Good Manufacturing Practices aren’t just regulatory requirements – they’re the foundation of operational excellence. We’ve implemented GMP systems across dozens of food facilities, and the impact goes far beyond compliance.

Clean-in-place (CIP) systems automate the cleaning and sanitization of production equipment. While the initial investment is significant, CIP systems reduce labor costs, improve cleaning consistency, and minimize downtime between production runs.

Pest control requires integrated pest management (IPM) programs that combine physical barriers, monitoring systems, and targeted treatments. Regular inspections and documentation are essential for maintaining certification and preventing contamination.

Staff hygiene protocols extend beyond basic handwashing. Implement comprehensive personal hygiene programs including proper protective equipment, training on contamination prevention, and regular health monitoring for production staff.

Implementing HACCP & ISO/FSSC 22000

HACCP (Hazard Analysis and Critical Control Points) must be treated as an ongoing operational discipline, not a one-time risk assessment. The seven HACCP principles provide a systematic approach to identifying and controlling food safety hazards:

- Hazard analysis – Identify potential biological, chemical, and physical hazards

- Critical Control Points (CCPs) – Determine points where hazards can be prevented or eliminated

- Critical limits – Establish measurable criteria for each CCP

- Monitoring procedures – Develop systems to monitor CCPs

- Corrective actions – Define responses when critical limits are exceeded

- Verification – Confirm the HACCP system is working effectively

- Documentation – Maintain records demonstrating the system is followed

ISO/FSSC 22000 builds on HACCP principles while adding management system requirements. This certification demonstrates your commitment to food safety and can be a competitive advantage in B2B sales.

Quality Control & Traceability

Lot coding and traceability systems enable rapid response to quality issues or recalls. Every ingredient batch and finished product lot should be traceable through your production records. Modern ERP systems can automate much of this tracking, reducing manual errors and improving response times.

FEFO (First Expired, First Out) inventory management is crucial for perishable ingredients. Unlike FIFO, which focuses on receipt date, FEFO prioritizes expiration dates to minimize waste and ensure product freshness.

Shelf-life testing validates your product’s stability over time. Conduct accelerated shelf-life studies during product development, then verify with real-time studies once production begins.

Recall simulation exercises test your traceability systems and response procedures. Conduct these exercises quarterly to identify gaps and improve response times.

Inventory & Waste Minimization

Effective inventory management directly impacts your bottom line. Food manufacturers typically see 15-25% of their costs tied up in inventory, making optimization crucial for cash flow and profitability.

FIFO (First In, First Out) rotation maintains ingredient freshness and minimizes spoilage. However, FIFO alone isn’t sufficient for perishable goods – you need systems that consider expiration dates, not just receipt dates.

Just-in-time (JIT) inventory reduces carrying costs and waste but requires reliable suppliers and accurate demand forecasting. Start with JIT for non-perishable ingredients while maintaining safety stock for critical items.

Cycle counting provides continuous inventory validation without the disruption of full physical counts. Focus cycle counting on high-value items and those with the greatest impact on production.

Lean tools like 5S workplace organization and value stream mapping identify waste in your production processes. We’ve seen manufacturers reduce waste by 20-30% through systematic application of lean principles.

| Inventory Method | Waste Reduction | Cash Flow Impact | Implementation Complexity |

|---|---|---|---|

| FIFO | 10-15% | Moderate | Low |

| JIT | 20-30% | High | High |

| Cycle Counting | 5-10% | Low | Medium |

| Lean Tools | 15-25% | Medium | Medium |

For more detailed guidance on inventory optimization, explore our insights on ERP solutions for food manufacturing.

Technology Stack for Scalable Control

The technology infrastructure you choose today will determine your ability to scale tomorrow. We’ve guided hundreds of food manufacturers through digital change, and the pattern is clear: companies that invest in integrated technology platforms early achieve better operational control and faster growth.

Selecting the Right ERP Backbone

Your ERP system is the central nervous system of your operation. It connects every aspect of your business – from ingredient procurement to customer delivery. The key is selecting a system that can grow with your business while handling the unique requirements of food manufacturing.

Requirements matrix development should include both current needs and future growth plans. Consider factors like multi-location support, regulatory compliance features, and integration capabilities with manufacturing equipment.

Scalability planning means choosing systems that can handle 10x your current volume without major reimplementation. Cloud-based ERP solutions offer the flexibility to scale resources as needed while maintaining system performance.

Integration APIs enable connections with specialized food manufacturing software, laboratory information systems, and e-commerce platforms. The ability to integrate with best-of-breed solutions prevents vendor lock-in and supports operational flexibility.

Food Manufacturing Management & NetSuite Optimization

NetSuite for food manufacturing provides comprehensive functionality designed specifically for food and beverage operations. The platform’s real-time financial management gives you instant visibility into costs, margins, and profitability at the product and batch level.

Batch traceability is built into NetSuite’s core functionality, automatically tracking ingredients from receipt through production to finished goods. This traceability supports both regulatory compliance and quality management.

Mobile warehouse management enables real-time inventory updates from handheld devices, reducing data entry errors and improving inventory accuracy. We’ve seen clients improve inventory accuracy from 70% to 99.6% after implementing mobile WMS capabilities.

For comprehensive information about NetSuite’s food manufacturing capabilities, visit NetSuite.com to explore their industry-specific solutions.

MES vs ERP: Who Does What?

Manufacturing Execution Systems (MES) and ERP systems serve complementary roles in food manufacturing management. Understanding their distinct functions helps you build an integrated technology stack that maximizes operational efficiency.

ERP systems manage business processes across the entire organization – financials, sales, purchasing, inventory, and customer relationships. They provide the business intelligence and planning capabilities needed for strategic decision-making.

MES systems focus on shop floor execution – production scheduling, work order management, quality control, and real-time production monitoring. They bridge the gap between ERP planning and actual production execution.

Shop floor control through MES provides real-time visibility into production status, equipment performance, and quality metrics. This visibility enables rapid response to production issues and continuous improvement initiatives.

Compliance records are automatically generated by MES systems, reducing manual documentation and improving audit readiness. This automation is particularly valuable for FDA and USDA inspections.

Overall Equipment Effectiveness (OEE) tracking through MES identifies opportunities for productivity improvement and predictive maintenance scheduling.

Leveraging IoT & Analytics

Sensor data from production equipment provides real-time insights into temperature, pressure, flow rates, and other critical parameters. This data enables proactive quality control and predictive maintenance.

Statistical Process Control (SPC) charts automatically generated from sensor data help identify trends and variations before they impact product quality. SPC implementation can reduce quality defects by 30-50%.

AI-powered demand forecasting uses historical sales data, seasonal patterns, and external factors to improve production planning accuracy. Better forecasting reduces inventory costs while improving customer service levels.

For more insights on technology integration in food manufacturing, explore our article on Cooking Up Success with ERP in the Food and Beverage Sector.

People, Culture & Continuous Improvement

Technology alone doesn’t create successful food manufacturing operations – people do. The most sophisticated ERP system or MES platform is only as effective as the team that operates it. We’ve learned that building a high-performance culture is just as important as implementing the right technology.

Building a High-Performance Workforce

Skills matrix development helps identify training needs and career development paths for your team. Food manufacturing requires a unique combination of technical skills, regulatory knowledge, and quality consciousness that takes time to develop.

Mentorship programs pair experienced workers with new hires to accelerate learning and maintain institutional knowledge. This is particularly important in food manufacturing where subtle process knowledge can significantly impact product quality.

Multilingual training is essential for diverse workforces. Food safety courses are now available in over 40 languages, ensuring that all team members can fully understand safety procedures and quality requirements.

Studies show that companies focusing on professional development and upskilling see higher employee retention. In an industry where skilled workers are increasingly difficult to find, retention becomes a competitive advantage.

Food Manufacturing Management Mindset

Creating a positive culture around food safety and quality requires more than training – it requires leadership commitment and employee engagement. Recognition programs that celebrate quality achievements and safety milestones reinforce the importance of these values.

Idea boards and suggestion systems give front-line workers a voice in continuous improvement. Some of the best process improvements come from the people who work with the equipment every day.

Champion of the Month programs recognize employees who demonstrate exceptional commitment to quality and safety. These programs boost morale while reinforcing company values.

Financial Discipline & KPI Tracking

Budget variance analysis should be conducted monthly to identify trends and address issues before they become problems. Food manufacturing margins are typically thin, making cost control essential for profitability.

Margin analysis at the product and batch level helps identify your most profitable products and processes. This analysis guides pricing decisions and resource allocation.

Overall Equipment Effectiveness (OEE) tracking identifies opportunities for productivity improvement. OEE improvements of 10-15% are common after implementing systematic measurement and improvement programs.

Customer satisfaction scores provide leading indicators of business health. Regular customer feedback helps identify quality issues before they become major problems.

Innovation & Sustainability Loop

R&D pipeline management ensures continuous product development while managing development costs. Successful food manufacturers typically invest 2-5% of revenue in new product development.

Eco-packaging initiatives respond to consumer demands for sustainability while potentially reducing packaging costs. Many sustainable packaging options provide cost savings through reduced material usage.

By-product valorization converts waste streams into revenue opportunities. Food manufacturers are increasingly finding ways to monetize what was previously considered waste, improving both profitability and sustainability.

Frequently Asked Questions about Food Manufacturing Management

What permits and certifications do I need before production?

The specific permits and certifications required depend on your product category, production location, and target markets. At minimum, you’ll need:

- Food facility registration with FDA (in the US) or equivalent regulatory body

- Food handler certifications for production staff

- Business licenses from local and state authorities

- Zoning permits for food manufacturing in your facility

- Water quality permits if you’re processing water-intensive products

Additional certifications like organic, kosher, or halal may be required depending on your target market. ISO 22000 or SQF certification can provide competitive advantages in B2B sales.

Start the permitting process early – some certifications can take 6-12 months to obtain.

How do GMP, HACCP, and ISO 22000 work together in daily operations?

These systems work together as layers of food safety management:

GMP (Good Manufacturing Practices) provides the foundation – facility design, equipment maintenance, personnel hygiene, and basic sanitation procedures. Think of GMP as the baseline requirements for safe food production.

HACCP builds on GMP by identifying specific hazards in your process and establishing critical control points to prevent, eliminate, or reduce those hazards. HACCP is process-specific and requires ongoing monitoring and verification.

ISO 22000 encompasses both GMP and HACCP while adding management system requirements like document control, internal audits, and continuous improvement processes.

In daily operations, your team follows GMP procedures for basic hygiene and sanitation, monitors HACCP critical control points during production, and uses ISO 22000 management system procedures for documentation and continuous improvement.

When should a growing plant migrate from spreadsheets to a full ERP/MES suite?

The transition point varies by company, but we typically recommend migration when you experience:

- Inventory accuracy below 95% – spreadsheets become unreliable as volume increases

- Manual data entry consuming more than 2 hours daily – automation becomes cost-effective

- Difficulty tracking batch genealogy – regulatory compliance becomes challenging

- Multiple production lines or shifts – coordination becomes complex

- Growth planning beyond current capacity – scalability becomes essential

The key is migrating before problems become critical. We’ve seen companies wait too long and face compliance issues or customer service problems that could have been avoided with earlier system implementation.

Start with a requirements assessment to identify your specific needs, then develop a phased implementation plan that minimizes disruption to ongoing operations.

Conclusion

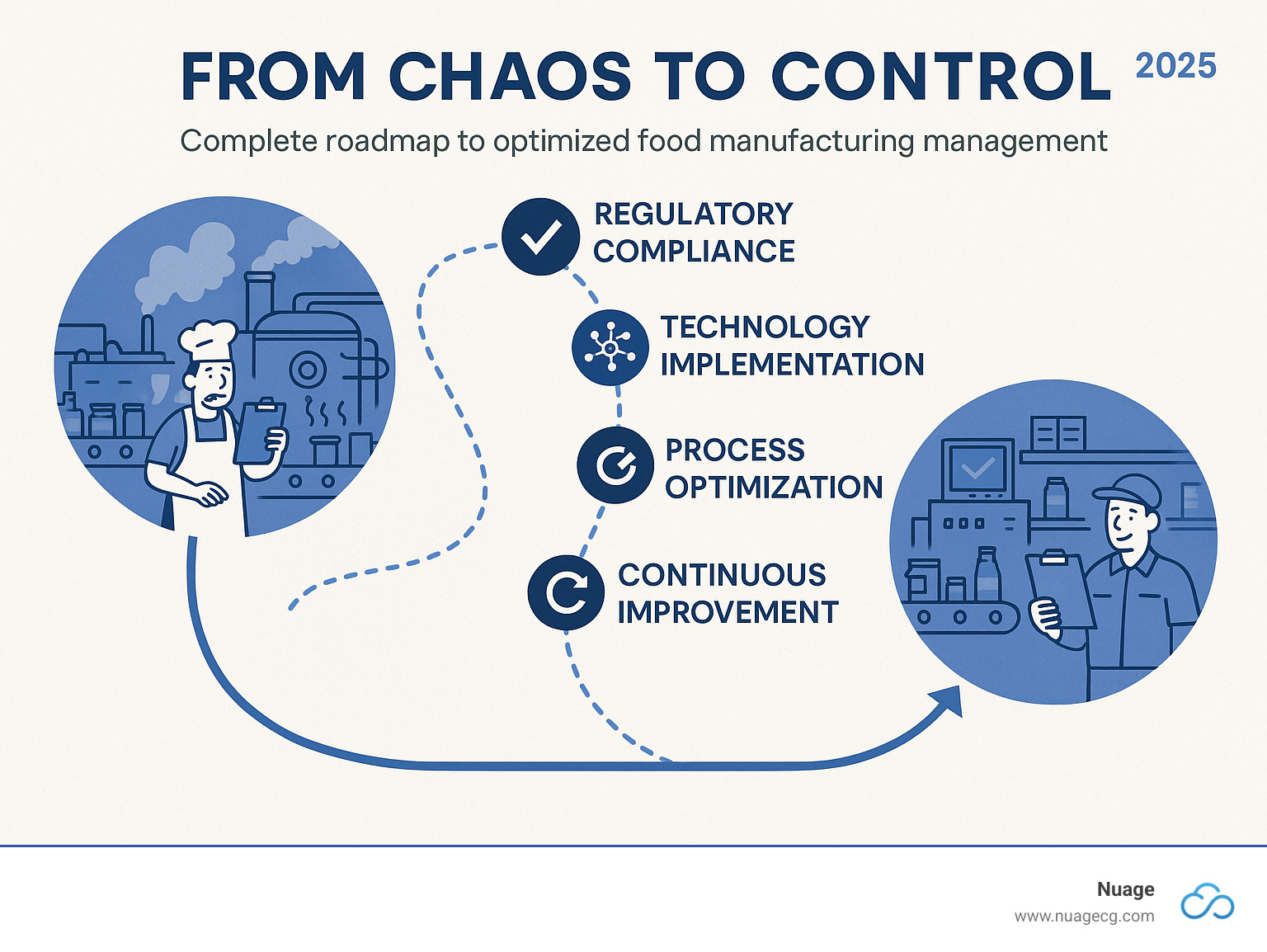

The journey from chaos to control in food manufacturing management isn’t just about implementing systems – it’s about building a foundation for sustainable growth. The companies that thrive in today’s competitive landscape are those that accept structured processes, integrated technology, and continuous improvement from the beginning.

Future-proofing your operation requires balancing current needs with growth potential. The decisions you make today about technology, processes, and people will determine your ability to scale tomorrow.

Agility in food manufacturing comes from having robust systems that can adapt to changing market conditions, regulatory requirements, and customer demands. This agility is built on a foundation of solid processes and integrated technology.

Compliance-first thinking isn’t just about avoiding problems – it’s about building quality into every aspect of your operation. Companies that excel at compliance typically excel at operational efficiency as well.

Digital change in food manufacturing is no longer optional. The companies that accept integrated ERP, MES, and analytics platforms gain competitive advantages that compound over time.

At Nuage, we’ve spent over 20 years helping food manufacturers steer this change. Our expertise in NetSuite and IFS Cloud implementations has shown us that successful digital change requires more than just software – it requires a partner who understands your industry and your growth objectives.

The path from chaos to control is challenging, but the rewards – operational excellence, regulatory compliance, and sustainable growth – make the journey worthwhile. With the right systems, processes, and partners, your food manufacturing operation can achieve the control and scalability needed to thrive in today’s competitive market.

For more comprehensive guidance on ERP solutions for food manufacturing, explore our detailed insights on ERP for Food and Beverage Industry.