Changing Your Beverage Business with Modern ERP Solutions

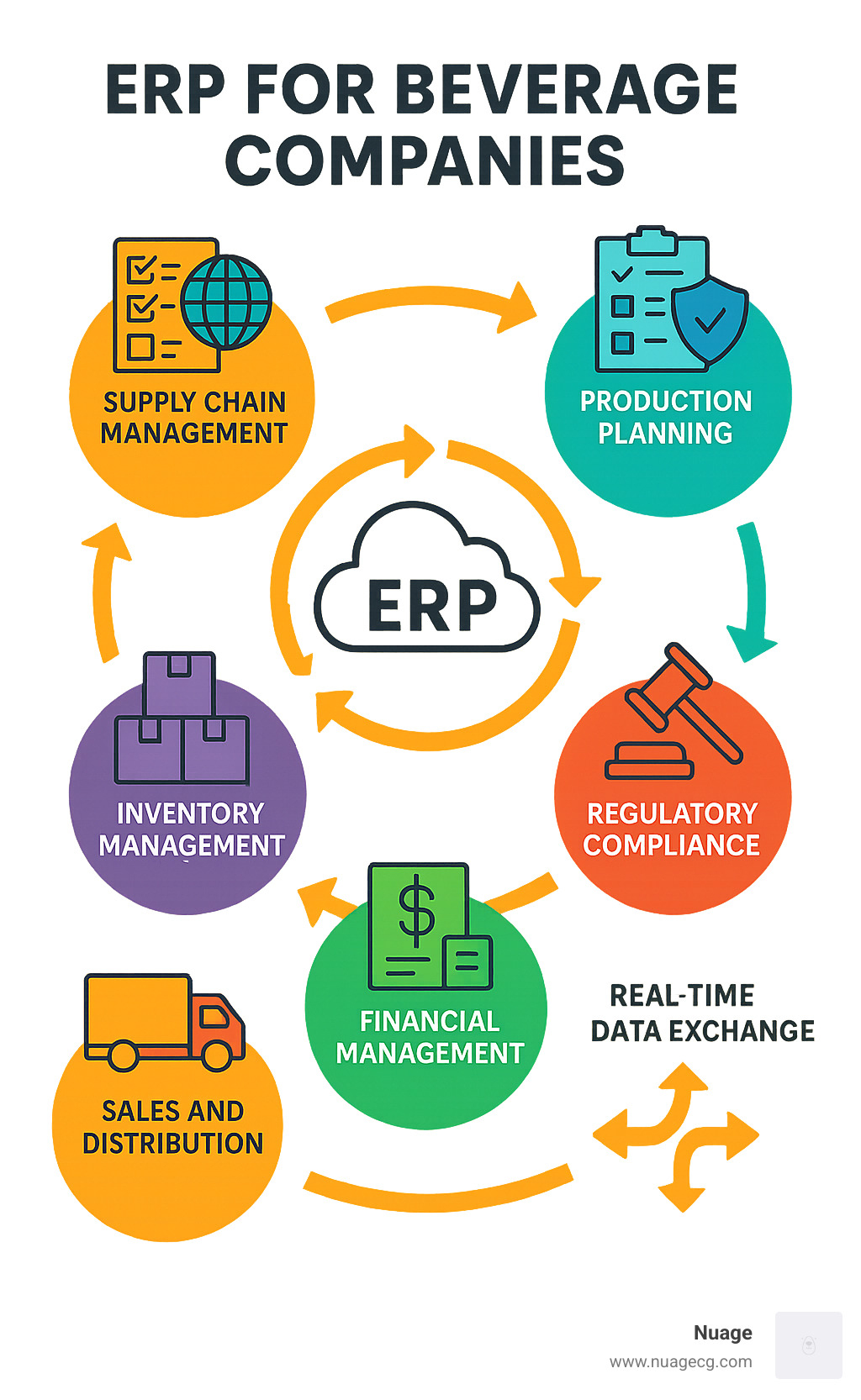

ERP for beverage companies is specialized software that integrates all aspects of beverage production, distribution, and sales into one unified platform. Here’s what you need to know:

- Purpose-built features: Recipe management, batch tracking, quality control, regulatory compliance

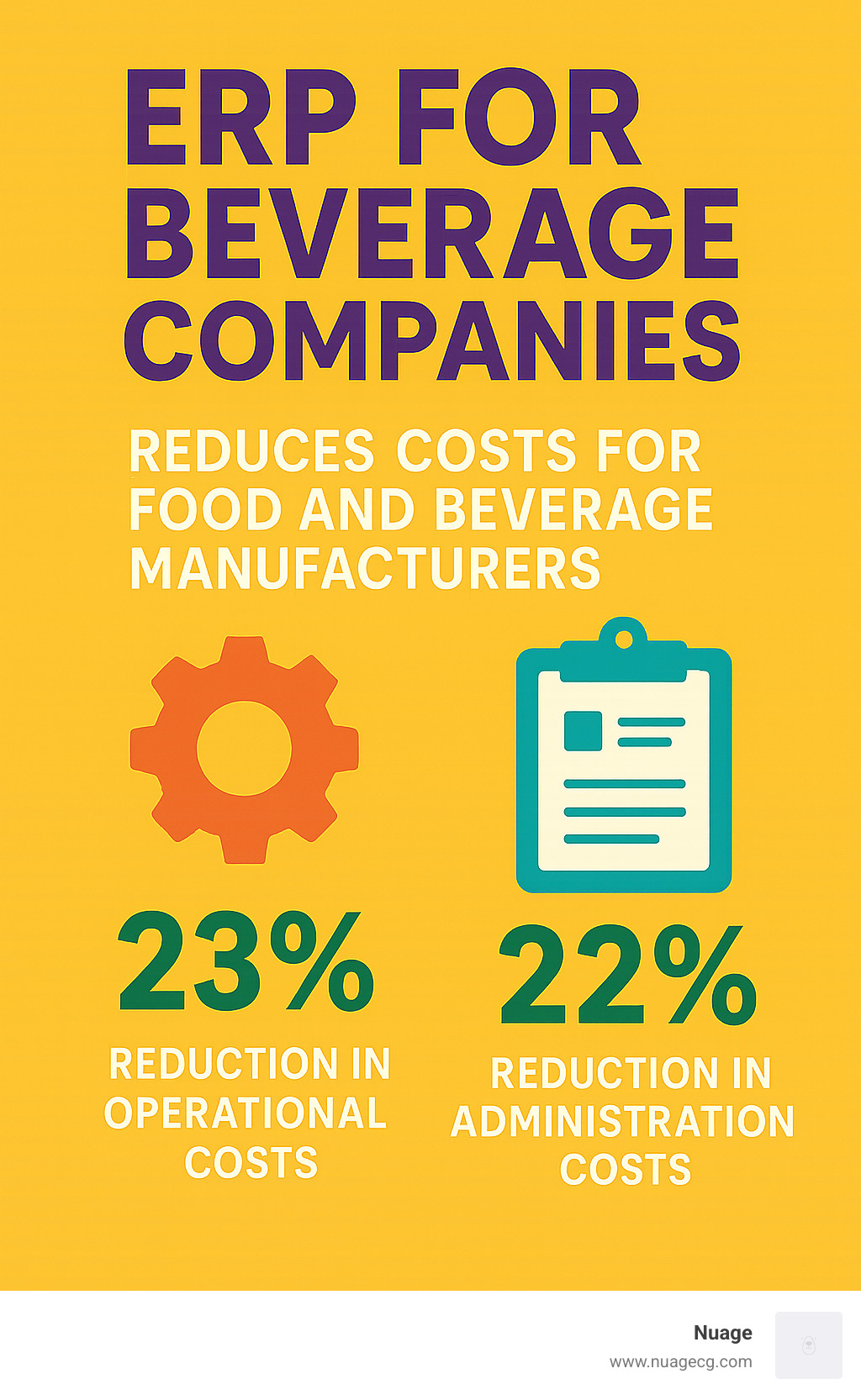

- Key benefits: 23% reduction in operational costs, 22% decrease in administration costs

- Top solutions: NetSuite Food & Beverage, IFS Cloud, BatchMaster, Crafted ERP, Infor CloudSuite

- Implementation timeline: Typically 3-6 months depending on complexity

The beverage industry faces unique challenges that generic ERP systems simply can’t handle. From managing perishable inventory and complex production schedules to navigating strict regulatory requirements and maintaining quality across batches, beverage manufacturers need specialized solutions.

As one brewery customer noted: “We want to focus on making great beer, not entering data and wrangling spreadsheets.” This sentiment echoes throughout the industry, where producers are looking to spend less time on administrative tasks and more time perfecting their products.

Modern beverage ERP systems deliver real-time visibility across your entire operation. They connect everything from procurement and production to quality control and distribution, eliminating silos and manual processes that drain resources and increase errors.

I’m Louis Balla, CRO and partner at Nuage with over 15 years of experience implementing ERP for beverage companies and driving digital change in supply chain operations, helping beverage manufacturers optimize their systems for maximum efficiency and growth.

Why Beverage Producers Need Purpose-Built ERP

When it comes to managing a beverage business, not just any ERP system will do. After years of helping beverage producers transform their operations, we’ve seen the struggles companies face when trying to make generic solutions fit their specialized needs.

Your beverage company isn’t like other manufacturers. You’re dealing with liquid gold that has expiration dates, batch variations, and a maze of regulations that would make any compliance officer sweat.

ERP for beverage companies needs to be as specialized as your products. The unique challenges you face demand purpose-built solutions that understand the rhythm of your business.

Your regulatory landscape is complex – from FDA requirements to TTB reporting for alcoholic beverages. Your inventory isn’t just sitting on shelves; it’s actively aging, expiring, or requiring precise temperature control. Your production requires meticulous batch tracking for quality and safety.

According to industry research, beverage manufacturers who implement specialized ERP systems see operational costs reduced by 23% and administrative costs decreased by 22%. That’s not just trimming the fat – it’s changing your entire operation.

The Big Picture: ERP for beverage companies

The regulatory environment for beverage producers isn’t just complicated – it’s constantly evolving. Food Safety Modernization Act (FSMA) requirements demand airtight documentation and traceability. If you’re producing alcoholic beverages, you’re also juggling Alcohol and Tobacco Tax and Trade Bureau (TTB) reporting requirements.

Beyond staying on the right side of regulators, you’re facing practical daily challenges:

Your SKU portfolio keeps growing as consumers demand more options. Your shelf-life controls need to ensure product quality from production to consumer. Your batch consistency is essential to maintaining flavor profiles customers love. And those seasonal demand fluctuations require planning that’s both flexible and precise.

A purpose-built ERP for beverage companies weaves all these considerations into smooth workflows that free up your team to focus on crafting exceptional beverages rather than drowning in paperwork.

Hidden Costs of “Good-Enough” Systems

“We’re managing fine with our current setup.” We hear this often from beverage companies running on a patchwork of basic accounting software, endless spreadsheets, and maybe a simple inventory tool. This approach might work when you’re small, but it quickly becomes your biggest liability as you grow.

The costs of sticking with “good-enough” systems aren’t always obvious on your balance sheet, but they’re draining your resources every day:

Your team spends hours maintaining manual spreadsheets, reconciling data that should flow automatically. Your departments operate in information silos, making decisions based on different versions of the truth. Your scalability is severely limited – systems that buckle just when you land that big new account. Your overhead keeps rising as you hire more people to manage administrative tasks rather than grow your business.

One craft brewery we partnered with was burning through over 20 hours weekly just updating spreadsheets to track production, inventory, and distribution. After implementing a beverage-specific ERP solution, those 20 hours shrank to just 2 hours of system oversight. That’s 18 extra hours every week they now spend on product innovation and market expansion.

The right NetSuite implementation for food and beverage companies doesn’t just save time – it transforms how you operate, giving you the foundation to scale without the growing pains that hold so many promising beverage companies back.

The Must-Have Feature Set for Winning Operations

When evaluating ERP for beverage companies, certain features aren’t just nice-to-have – they’re absolute necessities for operations that want to thrive rather than just survive. After helping dozens of beverage producers transform their businesses, we’ve identified the capabilities that truly move the needle.

Think of beverage-specific ERP as the difference between wearing off-the-rack clothes versus a custom suit. Here’s how specialized solutions compare to their generic counterparts:

| Feature | Generic ERP | Beverage-Specific ERP |

|---|---|---|

| Recipe/Formula Management | Basic BOM structure | Dynamic recipe scaling with potency tracking |

| Lot Traceability | Limited tracking | Full bi-directional lot tracking with recall functionality |

| Quality Control | Basic QC | Integrated HACCP, tasting panels, COA generation |

| Regulatory Compliance | Manual reporting | Automated TTB, FDA, nutritional reporting |

| Inventory Management | Standard inventory | Shelf-life tracking, FEFO, returnable packaging |

| Production Planning | Basic scheduling | Tank scheduling, CIP management, changeover optimization |

Quality & Compliance Engine

Quality and compliance might not be the sexiest parts of beverage production, but they’re absolutely critical to your survival and success. Modern ERP for beverage companies transforms these potential headaches into streamlined processes.

“The FDA doesn’t accept ‘we lost the paperwork’ as an excuse,” one of our craft brewery clients recently joked. With the right ERP, you’ll never have to make excuses because your system handles the heavy lifting automatically.

Your quality and compliance engine should include HACCP workflow automation that digitizes those critical control points and automated COA generation that creates quality documentation without manual effort. Allergen management capabilities ensure you’re tracking potential allergens throughout production.

The best systems maintain comprehensive audit trails that give you complete visibility into who did what and when. Automated regulatory reporting with built-in templates for FDA, TTB, and other agencies saves countless hours of administrative work.

We’ve seen clients reduce compliance-related administration by up to 75% after implementing these features. For deeper insights into related functionality, take a look at our guide on food distribution ERP.

Production & Inventory Control

The heartbeat of any beverage operation is its production floor and warehouse. Your ERP should strengthen this pulse, not complicate it.

Tank and equipment scheduling capabilities optimize your production assets, ensuring you’re getting maximum value from expensive equipment. Yield optimization features track and improve conversion rates – even small improvements here can dramatically impact your bottom line.

One wine producer we partnered with improved yield by just 1%, resulting in annual savings exceeding €500,000. That’s the power of precision in production management.

Expiry date management ensures you’re following FEFO principles (First Expired, First Out), critical for maintaining quality and minimizing waste. Mobile warehouse management with barcode or RFID scanning eliminates the errors that plague manual inventory systems.

Finance & Trade Management

The beverage industry’s financial landscape has unique contours that generic ERPs simply can’t steer effectively. Your system needs specialized tools to handle these complexities.

For companies selling across borders, multi-currency support is non-negotiable. Alcoholic beverage producers require excise tax calculation capabilities that automatically compute taxes by jurisdiction.

EDI capabilities streamline communication with major retailers and distributors, while automated rebate programs take the headache out of managing promotional pricing and volume discounts. Trade spend management helps you budget and analyze promotional activities so you can invest where it matters most.

ERP for Beverage Companies: Top Solutions to Toast

After reviewing dozens of systems and implementing various solutions for our clients, we’ve identified the top ERP for beverage companies that consistently deliver value. These platforms offer the specialized functionality beverage manufacturers need while providing the scalability to support growth.

NetSuite Food & Beverage Edition

NetSuite has become a favorite among our beverage clients, and for good reason. As certified NetSuite implementation partners at Nuage, we’ve seen how this cloud-based platform transforms operations from chaotic to streamlined.

What makes NetSuite particularly valuable for beverage producers? It starts with real-time visibility across your entire business. No more waiting for reports or wondering if your inventory numbers are accurate. Every department works from the same up-to-the-minute information.

The platform excels at omnichannel ordering, allowing you to manage sales whether they’re coming through your website, retail partners, or distribution channels. With native lot traceability, you can track ingredients from receipt through production and all the way to customer delivery – essential for quality control and potential recalls.

NetSuite’s cloud architecture means your team can access critical information from anywhere – perfect for companies with multiple facilities or teams on the road. And since updates happen automatically, you’re always working with the latest features without disruptive upgrade projects.

Want to learn more about changing your beverage operation with NetSuite? Visit our NetSuite page or check out our detailed article on NetSuite for Food and Beverage.

IFS Cloud for Process Manufacturing

For beverage manufacturers with complex production processes or global operations, IFS Cloud delivers powerful capabilities that go beyond standard ERP functionality. At Nuage, we’ve implemented IFS for several beverage clients who needed advanced manufacturing capabilities alongside comprehensive business management tools.

What sets IFS Cloud apart? Its AI-driven maintenance capabilities help prevent equipment failures before they happen – a game-changer for beverage producers where downtime can mean thousands in lost production. The platform’s advanced quality management tools ensure consistent product excellence, while ESG dashboards make it easy to track and report on sustainability initiatives.

Global beverage companies particularly appreciate IFS Cloud’s support for international regulatory compliance and multi-site management. The system unifies operations across different locations while respecting local requirements.

IFS Cloud’s integrated manufacturing execution capabilities give production managers real-time visibility into shop floor activities, while powerful planning tools optimize scheduling to maximize efficiency and throughput.

Find how IFS Cloud can lift your beverage manufacturing operation on our IFS Cloud page.

Niche Add-Ons & Extensions

Even the most comprehensive ERP platforms sometimes benefit from specialized add-ons that address specific beverage industry needs. Think of these as the perfect garnish for your ERP cocktail!

Mobile picking applications can dramatically improve warehouse efficiency – we’ve seen beverage distributors cut picking times by 30% with the right mobile tools. If you handle direct store delivery, specialized DSD routing software optimizes delivery schedules and helps manage in-store merchandising activities.

Taproom or retail operations? Connected Point of Sale solutions integrate directly with your ERP, eliminating manual sales entry and providing real-time visibility into consumer preferences. For data-driven decision making, industry-specific Business Intelligence visualizations transform complex data into actionable insights.

Implementation, ROI & Best Practices

Implementing ERP for beverage companies isn’t just about installing new software—it’s about changing how your business operates. After helping dozens of beverage producers modernize their operations, we’ve learned that success comes from thoughtful planning and a people-first approach.

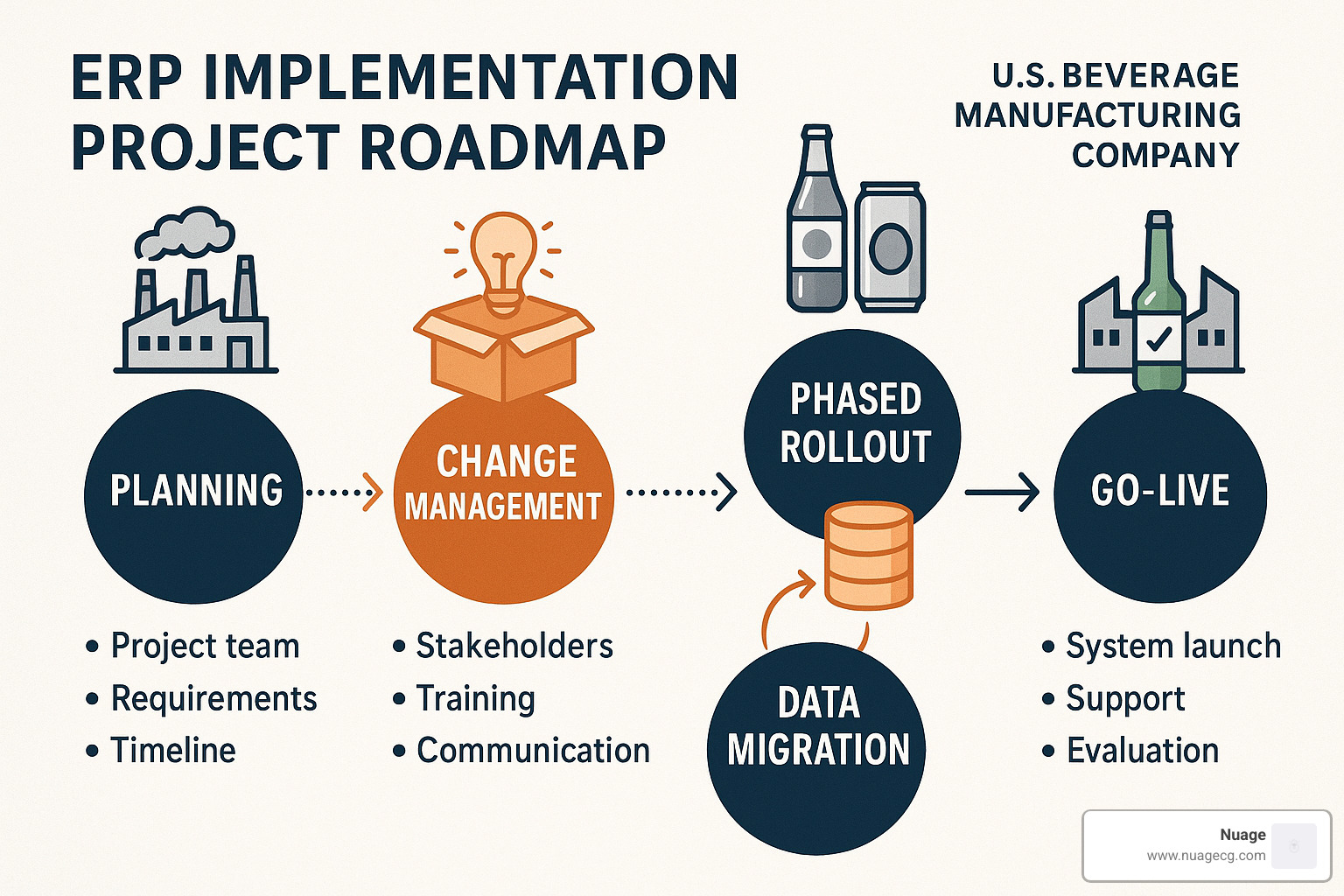

Think of ERP implementation as brewing a perfect batch—you need the right ingredients, proper timing, and careful attention throughout the process. The recipe for success typically includes change management to prepare your team, a phased rollout approach, meticulous data migration from legacy systems, establishing clear KPI baselines to measure success, comprehensive user training, and process optimization.

“The biggest mistake we see is companies rushing to go live without properly preparing their teams,” explains our implementation director. “Technology is only half the equation—people make the system work.”

The good news? The investment pays off quickly. Our beverage clients typically see complete payback within 6 months of going live, with an impressive average ROI of 250% over the first three years.

Calculating ROI for ERP for beverage companies

When tallying up the returns from your ERP investment, look beyond the obvious numbers. The real value comes from multiple areas:

Labor savings emerge when your team spends less time on manual data entry and more time on strategic work. A mid-sized winery we worked with reduced administrative headcount by 15% while increasing output by 22%—their staff was finally free to focus on making great wine instead of wrestling with spreadsheets.

Yield gains become noticeable as production efficiency improves. Better recipe management and inventory control typically reduce waste by 3-5%, which adds directly to your bottom line.

Faster financial close transforms month-end from a dreaded marathon to a manageable sprint. Most of our clients reduce closing time from 10+ days to just 3-5 days, giving management access to critical financial insights when they’re still relevant for decision-making.

Reduced recalls and waste, inventory optimization, improved customer service, and compliance efficiency round out the ROI picture.

Common Pitfalls & How to Avoid Them

After 20+ years of implementing ERP for beverage companies, we’ve seen the same challenges trip up even the most prepared organizations. Here’s how to sidestep the common pitfalls:

Scope creep happens when the project expands beyond its original boundaries. It’s tempting to fix every business challenge at once, but this approach often leads to delays and budget overruns. Instead, focus on core functionality for phase one and save refinements for later phases.

Under-training is a false economy. Your team needs more than a quick overview to use the system effectively. Invest in role-specific training programs that address real-world scenarios your staff encounters daily.

Poor master data can undermine even the best ERP system. Take time to clean and validate your product masters, customer records, and supplier information before migration. Establish clear data governance procedures to maintain quality going forward.

Lack of executive sponsorship dooms many promising projects. When leadership treats ERP as “just an IT project,” user adoption suffers. Successful implementations have visible, active support from the C-suite.

Resistance to change is natural but manageable. Involve key users in design decisions, communicate benefits clearly, and celebrate early wins to build momentum.

For more insights on implementing ERP in food and beverage operations, check out our article on ERP solutions for food.

Frequently Asked Questions about ERP for Beverage Companies

What is the typical timeline to deploy an industry ERP?

When clients ask us about implementation timelines for ERP for beverage companies, we typically share that most projects take between 3 and 9 months from kickoff to go-live. Several factors influence this timeline:

Company size matters—a regional craft brewery with a single facility will move faster than a multi-national beverage corporation with facilities across continents. The scope of what you’re implementing also significantly impacts the timeline.

Data migration is often the hidden time-consumer. Bringing years of historical data into your new system requires careful cleaning and validation. Similarly, if you need your ERP to talk to other systems like e-commerce platforms or specialized production equipment, these integrations add complexity.

At Nuage, we’ve refined our approach over 20 years to favor phased implementations. Most of our beverage clients see their first phase go live within 4-6 months, giving them quick wins while building toward their complete solution.

How does a beverage ERP handle recalls in minutes?

Recalls—the scenario that keeps beverage executives up at night. Modern ERP for beverage companies transforms this potential nightmare into a manageable process through powerful lot traceability features.

Think of it as a digital family tree for every product you make. Your ERP maintains complete relationships between raw materials, production batches, and finished goods. When a quality issue arises, you can instantly trace forward to see every product affected and backward to identify the source.

With pre-configured trace reports, you can generate a complete picture of the situation in minutes. The system quickly identifies which customers received potentially affected products, when they received them, and in what quantities.

One craft soda manufacturer we work with conducts monthly mock recalls and consistently completes the full trace process in under 5 minutes—a process that used to take them days with spreadsheets and paper records.

Cloud vs. On-premise—what’s safer for my proprietary formulas?

“But if our secret recipe is in the cloud, won’t it be easier to hack?” This concern comes up in nearly every conversation we have with beverage manufacturers considering cloud ERP solutions.

The reality might surprise you. Modern cloud platforms like NetSuite and IFS Cloud typically offer more robust security than on-premise systems. Cloud providers invest millions in security expertise, employ teams dedicated to protecting your data, and continuously update their systems against emerging threats.

Your data in these systems is encrypted both while being transmitted and when stored. Access controls can be finely tuned to ensure only authorized personnel can view sensitive information like proprietary formulas. Leading cloud providers maintain rigorous security certifications including SOC 1, SOC 2, and ISO 27001.

At Nuage, we help clients implement appropriate security controls regardless of deployment model. For more information about how we approach security in our implementations, visit our NetSuite ERP consultants page.

Conclusion

Implementing the right ERP for beverage companies isn’t just a technology upgrade—it’s a strategic business decision that can transform your entire operation. In today’s competitive landscape, where regulatory demands increase and margins tighten, having the right systems in place makes all the difference between struggling and thriving.

Throughout this article, we’ve explored how beverage manufacturers face unique challenges that demand specialized solutions. Your business deserves more than a generic ERP system trying to fit a square peg into a round hole. From managing complex recipes and ensuring lot traceability to maintaining regulatory compliance and controlling quality, purpose-built ERP systems address these specific needs while delivering remarkable operational and financial benefits.

At Nuage, we bring over 20 years of hands-on experience implementing ERP solutions for beverage producers of all sizes. This experience gives us a unique perspective on what truly works—and equally important, what doesn’t—for companies like yours. We pride ourselves on our vendor-agnostic approach, ensuring we recommend the solution that genuinely fits your specific needs, whether that’s NetSuite, IFS Cloud, or another platform.

We understand that choosing and implementing an ERP system represents a significant decision that will impact your business for years to come. That’s why we take the time to truly understand your unique challenges, goals, and processes before making any recommendations.

Ready to explore how a modern ERP solution can transform your beverage operation? Our team of NetSuite ERP consultants is available for a friendly, no-obligation consultation to help you steer the options and develop a practical roadmap for success. With the right technology partner and purpose-built ERP for beverage companies, you can focus on what you do best—creating exceptional beverages that your customers love.