Why NetSuite ERP for Manufacturing is Essential Today

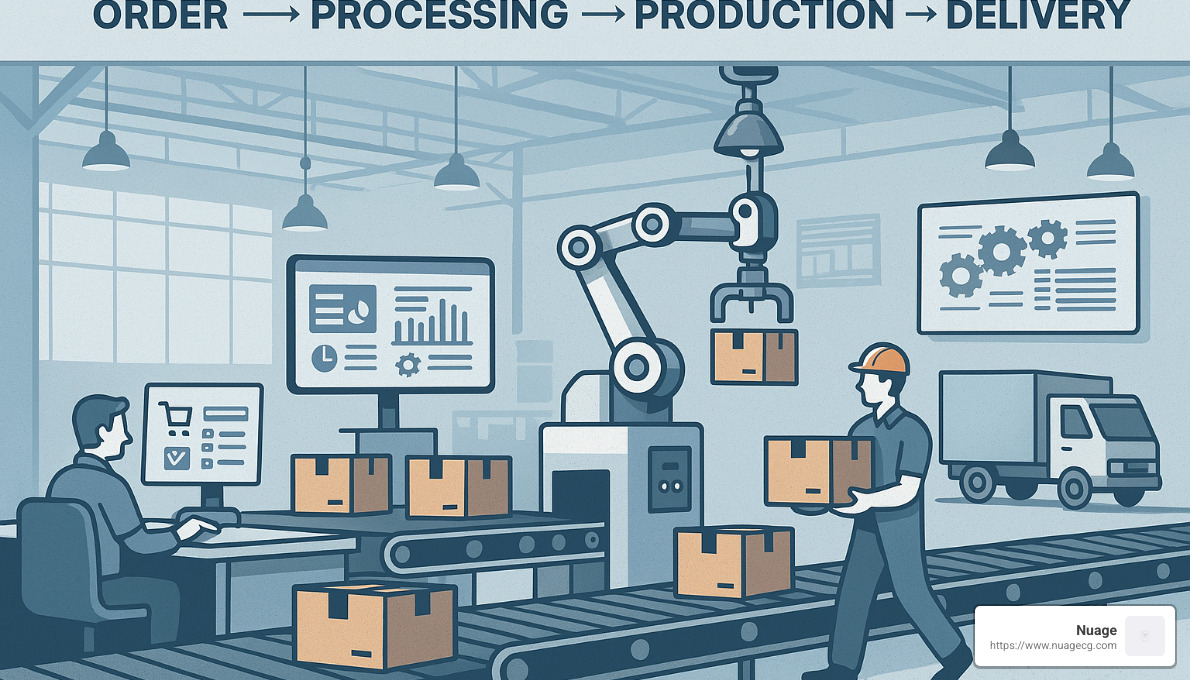

NetSuite ERP for manufacturing is a cloud-based solution that integrates production, inventory, finance, supply chain, and customer management into one unified system. It helps manufacturers tackle core challenges like managing complex processes, improving visibility, optimizing resources, and enabling global growth.

Here’s a quick overview of why it’s critical for modern manufacturing:

- Integrated Platform: Connects all aspects of business—from the shop floor to the top floor—in one platform.

- Real-Time Visibility: Provides live insights into inventory, production, financial performance, and order status.

- Operational Efficiency: Automates manual tasks, saving time and cutting operational costs.

- Improved Decision-Making: Detailed analytics help leaders make smarter, data-driven decisions.

As a Chief Revenue Officer at Nuage with over 15 years specializing in digital change, I’ve guided numerous companies on their journey with NetSuite ERP for manufacturing, ensuring integration success and improved business outcomes. In this review, we’ll dive deeper into how NetSuite ERP helps manufacturers stay agile and competitive.

NetSuite ERP for manufacturing basics:

– ERP solutions for manufacturing

– ERP solutions for food

– Food industry digital change

What is NetSuite ERP for Manufacturing and Why Does It Matter?

Manufacturing has evolved dramatically from traditional assembly lines to today’s smart factories. As we steer the fourth industrial revolution—Industry 4.0—manufacturers face both unprecedented challenges and exciting opportunities. In this rapidly changing landscape, NetSuite ERP for manufacturing has become a critical solution for companies determined to stay competitive and drive sustainable growth.

At its core, NetSuite ERP for manufacturing is a comprehensive, cloud-based solution that replaces disconnected systems with an integrated platform built specifically for manufacturing operations. It brings together everything from production planning and shop floor control to financial management and customer relationships in one centralized system.

Recent industry research tells an interesting story—a Deloitte survey found that 76% of manufacturing executives now place investing in digital supply chain tools at the top of their priority list. This shift makes perfect sense when you consider what today’s manufacturers are up against:

Supply chain disruptions have become the norm, requiring much greater visibility and control. Labor shortages continue to challenge even the best-run operations. Many facilities face capacity limitations that demand smarter production planning. Meanwhile, customer expectations for quality and speed keep rising, and global competition intensifies daily.

One manufacturing leader shared with us after implementing NetSuite: “It would be impossible to continue to grow as we have without NetSuite. We have customer financial, production and manufacturing data all in one place. And we’re still not utilizing everything.”

This statement captures exactly why NetSuite ERP for manufacturing matters so much—it provides the digital foundation necessary for modern manufacturing success, helping companies adapt quickly while optimizing operations. When properly implemented, it becomes the nervous system connecting every aspect of your manufacturing business.

Want to see how a Manufacturing Execution System can transform your operations? Or learn more about ERP Systems for Manufacturing? We’ve got you covered.

The Evolution of Manufacturing ERP Systems

Manufacturing ERP systems have undergone a remarkable change over the decades. What started as simple Material Requirements Planning (MRP) systems in the 1960s has evolved into sophisticated, cloud-based platforms that integrate every aspect of manufacturing operations.

The journey from legacy systems to modern ERP solutions reflects how manufacturing needs have changed over time:

Back in the 1960s-1970s, MRP Systems focused primarily on production planning and inventory control—basic but for their time. By the 1980s, MRP II expanded capabilities to include shop floor control, capacity planning, and basic financial management. The 1990s-2000s saw the rise of On-Premises ERP systems that introduced integrated business management across departments but required significant IT infrastructure and expertise to maintain.

Today’s Cloud-Based ERP solutions represent a quantum leap forward, delivering comprehensive functionality with greater flexibility, accessibility, and dramatically reduced IT overhead.

“As technology becomes more accessible, and global supply chains make manufacturing more complex, ERP systems have emerged as a powerful tool. By breaking down siloed processes, centralizing business aspects and providing specialized features for the manufacturing industry, these systems offer a comprehensive solution.”

The shift to cloud-based solutions like NetSuite ERP for manufacturing is truly game-changing. Unlike traditional on-premises systems with their hardware investments and complicated updates, cloud ERP gives you automatic updates that keep functionality current without disruption. You’ll enjoy reduced IT costs, anywhere access to critical information, easier scalability as your business grows, and improved security to protect your valuable data.

At Nuage, we’ve guided numerous manufacturing clients through the transition from outdated, siloed systems to integrated NetSuite environments. One mid-sized discrete manufacturer told us that after implementation, they gained efficiencies equivalent to six full-time employees just by replacing their legacy system with NetSuite. That’s the kind of practical, bottom-line impact that makes a real difference.

Key Challenges Facing Modern Manufacturers

Today’s manufacturing landscape is more complex and challenging than ever before. Understanding these challenges helps explain why NetSuite ERP for manufacturing has become such a vital solution for forward-thinking companies.

Supply chain disruptions have become alarmingly common. The past few years have taught manufacturers harsh lessons about vulnerability in their supply networks. Companies struggle with unpredictable material availability, volatile shipping costs, limited supplier visibility, and difficulty adapting to sudden changes. NetSuite ERP for manufacturing tackles these issues head-on by providing real-time visibility across your entire supply chain. This allows you to spot potential disruptions before they impact production, while powerful demand planning helps maintain optimal inventory levels without excessive carrying costs.

Labor shortages continue to plague manufacturing operations nationwide. Finding and keeping skilled workers has never been more difficult, especially as experienced team members retire, taking valuable knowledge with them. NetSuite helps address these workforce challenges by automating routine tasks and streamlining workflows with intuitive interfaces that reduce training time. Mobile capabilities let your team access and update information right from the shop floor, boosting productivity even with fewer hands on deck.

Capacity limitations create constant pressure to do more with less. Balancing customer demand with available resources, managing multiple facilities, scheduling maintenance without disrupting production, and accurately forecasting capacity needs are daily challenges. With NetSuite ERP for manufacturing, you gain sophisticated planning and scheduling tools offering both finite and infinite capacity options. Real-time dashboards help your managers quickly identify bottlenecks and optimize resource allocation before small issues become big problems.

Quality and compliance demands grow more stringent every year. From industry-specific regulations to rising customer expectations, manufacturers must deliver consistent quality while maintaining exhaustive documentation. NetSuite’s quality management features allow you to define inspection plans, establish clear pass/fail criteria, and maintain comprehensive documentation that simplifies compliance and satisfies even the most demanding customers.

Global competition has transformed manufacturing into a worldwide marketplace. This creates pressure to match international pricing while navigating complex currency, language, tax, and regulatory requirements. NetSuite ERP for manufacturing supports your global ambitions with robust multi-currency, multi-language, and multi-subsidiary capabilities that provide real-time visibility across operations anywhere in the world.

These challenges aren’t going away—in fact, they’re likely to intensify. That’s why having the right ERP system isn’t just a technology decision; it’s a strategic imperative for manufacturing success.

Core Features of NetSuite ERP for Manufacturing

When it comes to streamlining your manufacturing operations, NetSuite ERP for manufacturing packs a powerful punch with an impressive lineup of features. Designed specifically to meet the unique needs manufacturers face every day, NetSuite goes beyond traditional ERP systems by offering deep functionality custom just for you—whether you’re assembling discrete components, mixing batches, or managing global production.

Let’s explore the core features that make NetSuite ERP a favorite among manufacturers.

Production Management and Shop Floor Control

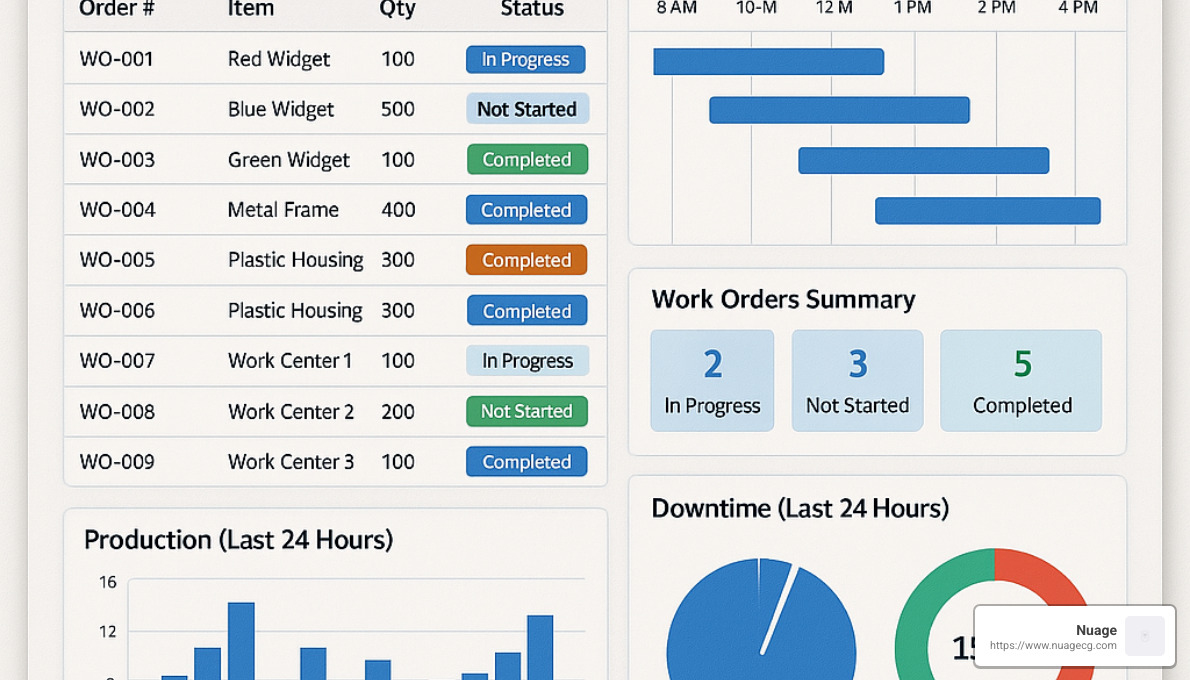

At the heart of your manufacturing business is production—and NetSuite has this covered from start to finish. Its robust production management tools give manufacturers complete visibility and control across the entire production cycle.

With NetSuite, managing your Bill of Materials (BOM) becomes a breeze. It supports advanced, multi-level BOM types—perfect for complex assemblies or custom-engineered products. You can easily track, manage, and modify work orders, and the built-in Engineering Change Orders (ECO) feature ensures your manufacturing teams are always aligned on the latest product changes. As one happy client shared: “We can track inventory with a click, drill right into sub-assemblies, and plan production and purchasing faster than ever.”

On the shop floor itself, NetSuite shines with user-friendly tablet applications designed specifically for tough manufacturing environments—even with gloves on! Workers can update production data in real-time directly from their workstations, scan barcodes efficiently, and clearly manage work centers. NetSuite’s intuitive interactive screens eliminate paperwork and dramatically reduce errors.

And when it’s time to schedule production, you’ll appreciate NetSuite’s visual, drag-and-drop scheduling tools. Easily create production routings, perform finite or infinite capacity scheduling, and instantly see your entire schedule displayed visually in Gantt charts. Say goodbye to cumbersome spreadsheets and guesswork.

Inventory and Supply Chain Management

Effective inventory management is crucial for manufacturers, and NetSuite understands this deeply. It provides total visibility across multiple inventory locations, automating replenishment based on demand forecasts, intelligently allocating stock, and providing granular tracking by bins and locations. This helps you keep just enough inventory to meet demand without excess costs and waste.

Speaking of demand, NetSuite has built-in statistical forecasting and scenario-planning tools that turn historical data into accurate demand forecasts. Its intuitive demand planning workbench makes collaboration among your teams easier, helping you prepare for market fluctuations before they happen.

NetSuite’s supply chain management functionality covers everything from vendor and purchase order management to receiving, inspection, and landed cost calculations—giving you a complete view of your procurement lifecycle. One of our manufacturing clients remarked: “We evaluated Microsoft Dynamics and SAP, but NetSuite provided simpler cloud access, seamless upgrades, and enabled us to streamline our entire quote-to-cash and procurement processes.”

For products requiring detailed traceability, NetSuite supports lot tracking and serial number management, allowing you to quickly trace items through production and beyond. This ensures compliance and gives peace of mind, especially for regulated industries.

To learn more about optimizing your order processes with NetSuite, check out our detailed article on NetSuite Order Management.

Financial Management and Reporting

Having manufacturing data closely integrated with financial management is essential for profitability. Thankfully, NetSuite brings finance and production together beautifully.

Financially speaking, NetSuite provides full-featured modules including general ledger, accounts receivable and payable, fixed asset management, and tax management. By tightly integrating these financial modules with your manufacturing processes, NetSuite reduces manual data entry, improves accuracy, and ensures your finance team always has real-time insight into your company’s performance.

NetSuite also delivers powerful manufacturing cost accounting capabilities. With standard costing, actual cost tracking, variance analysis, and Work-In-Process (WIP) accounting, you’ll gain deep visibility into all manufacturing costs. This allows you to spot inefficiencies and manage costs better, boosting profit margins.

When it’s time for reporting, NetSuite’s real-time dashboards and customizable financial statements provide instant access to detailed analytics. You can drill down into specific transactions to investigate variances, create custom reports, and keep your finger on the pulse of your business with insightful KPIs.

If you’re operating globally, NetSuite effortlessly handles multi-currency transactions and multi-subsidiary consolidation. This means you can focus on growing internationally without getting bogged down in currency conversions or complicated intercompany accounting.

For insights into implementation costs, check out our guide on NetSuite Implementation Costs or visit our main NetSuite ERP page for more details.

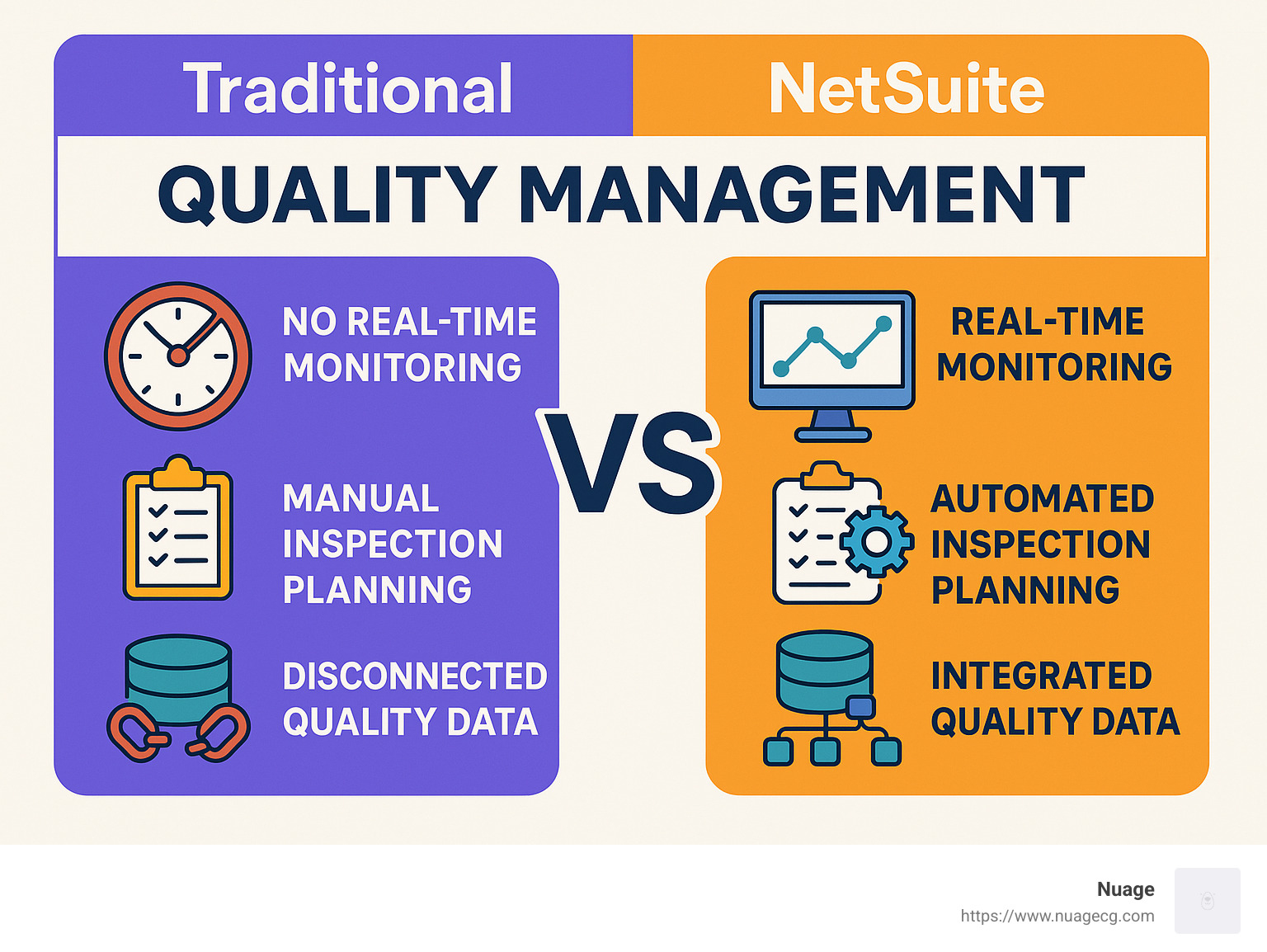

Quality Control and Compliance

Quality isn’t just nice-to-have—it’s critical. NetSuite ERP includes comprehensive quality management tools to ensure that your products consistently meet customer expectations and regulatory standards.

You can easily set up inspection plans at various checkpoints, define clear pass/fail criteria, collect quality data directly into the system, and quickly address non-conformance issues when they occur. This reduces errors, minimizes waste, and boosts customer satisfaction.

For regulatory compliance needs, NetSuite provides detailed audit trails, electronic signatures, secure document management, and configurable workflows—making it easy to stay compliant, especially in highly-regulated industries like food, pharmaceuticals, or aerospace.

NetSuite also supports environmental, health, and safety (EHS) initiatives. You can track incidents, manage corrective actions, generate compliance reports, and manage safety training easily within the system. Keeping your workers safe and compliant has never been simpler.

With all these powerful features at your fingertips, it’s easy to see why NetSuite ERP for manufacturing is a trusted solution for manufacturers worldwide. At Nuage, we’ve been helping businesses transform their operations for over 20 years. Whether you’re exploring NetSuite ERP or evaluating the best ERP solution for your needs, our team is here to guide you every step of the way. To learn more, explore our Nuage NetSuite page.

Benefits of Implementing NetSuite ERP in Manufacturing

Implementing NetSuite ERP for manufacturing offers a powerful way for manufacturers to lift their business—from streamlining day-to-day operations, to gaining greater visibility, to seamlessly managing global complexities. Simply put, NetSuite ERP connects your business in ways that legacy systems just can’t match.

Let’s dig deeper into the key benefits that manufacturers experience after adopting NetSuite ERP.

Streamlining Operations and Reducing Costs

One of the most immediate wins you’ll notice after implementing NetSuite ERP for manufacturing is the ability to simplify and streamline your operations. Say goodbye to those endless spreadsheets and manual processes that drain your team’s time (and patience!). Instead, NetSuite automates routine tasks like order processing, inventory management, production scheduling, and financial transactions.

By automating these processes, you’ll reduce manual data entry and eliminate costly errors. Because NetSuite unifies all your data into one integrated system, information flows smoothly from quotes to orders to production—no duplicate entry required. With NetSuite, inventory reordering becomes automatic, production schedules align effortlessly with demand, and financials update in real-time.

One of our manufacturing clients shared, “By replacing our old system with NetSuite, we’ve gained efficiencies equivalent to six full-time employees.” Imagine freeing up your team to focus on innovation and growth instead of repetitive tasks. It’s like having extra pairs of hands working quietly behind the scenes.

NetSuite also helps you optimize inventory levels across all your locations. Demand-based planning, automated replenishment, and clear inventory visibility mean you’ll carry just the right amount of stock. NetSuite users typically see inventory carrying costs decrease by around 20%, giving a nice boost to cash flow.

Additionally, NetSuite ERP improves resource utilization across your whole operation. From labor and equipment scheduling to materials and space planning, NetSuite’s built-in tools help you maximize productivity, reduce downtime, and even uncover hidden production capacity you didn’t know existed.

All these improvements mean fewer headaches and lower operational costs. And let’s face it—who doesn’t want that?

Enhancing Visibility and Decision-Making

When you run your manufacturing operations on NetSuite ERP, you’ll have a crystal-clear view of what’s happening across your business—in real-time. Gone are the days when you had to wait days or weeks for reports to know how things were going.

With NetSuite’s real-time dashboards and reporting features, everyone from the shop floor manager to the CFO has the critical information they need right at their fingertips. Role-based dashboards provide relevant insights custom specifically to each person’s job, highlighting important KPIs and alerting you to any issues immediately.

NetSuite ERP doesn’t just show you what’s happening—it helps you understand why it’s happening and what to do next. With built-in business intelligence and analytics, you’ll examine trends, benchmark performance, and even use predictive analytics to anticipate future outcomes.

This level of visibility takes decision-making from gut feelings to data-driven confidence. As one executive told us, “NetSuite gives us insight and control over our entire workflow. We can make decisions based on real data, not gut feelings.”

NetSuite also promotes better teamwork and collaboration. With shared, real-time data accessible across functions, teams can coordinate planning, quickly address issues, and communicate effortlessly—breaking down silos once and for all.

Supporting Global Manufacturing Operations

If your manufacturing business has global ambitions—or you’re already operating internationally—you know how complex it can get. From managing multiple currencies and languages to staying compliant with ever-changing international regulations, global operations can quickly become overwhelming.

Thankfully, NetSuite ERP for manufacturing makes going global simpler and less stressful. With robust multi-currency and multi-language capabilities, NetSuite allows your team to easily handle international transactions and operate seamlessly in local languages and formats.

NetSuite’s built-in global tax engine automatically calculates and reports taxes accurately in each jurisdiction. It also helps you track and manage regulatory requirements and documentation, simplifying international compliance and reducing risk.

Managing a global supply chain is also far easier with NetSuite. Whether you’re working with vendors across continents, handling international shipping, or calculating landed costs, NetSuite provides real-time visibility and control every step of the way.

For manufacturers with multiple subsidiaries or entities, NetSuite streamlines intercompany transactions, consolidates reporting, and provides role-based security so each team accesses only the information they need.

In short, NetSuite ERP gives growing manufacturers the tools they need to confidently expand and thrive on the global stage—without losing sleep (or sanity).

At Nuage, we’ve spent over 20 years helping manufacturers like you steer complex ERP implementations and open up real-world benefits. As proud partners of industry-leading platforms like NetSuite, we’re not here to sell you software; we’re here to help you select, implement, and thrive with the right ERP solution for your unique needs.

Curious about how NetSuite ERP can transform your manufacturing business? Feel free to explore NetSuite’s manufacturing solutions or connect directly with our team at Nuage—we promise we’ll keep the ERP jargon to a minimum! 😉

Types of Manufacturers Benefiting from NetSuite ERP

Manufacturing operations come in all shapes and sizes, and each has unique needs and challenges. One of the biggest advantages of NetSuite ERP for manufacturing is its ability to flexibly support different manufacturing models—from discrete assembly to process manufacturing and even outsourced production. Let’s explore how NetSuite fits seamlessly into different manufacturing environments.

Discrete Manufacturing

Discrete manufacturers create individual, finished products by assembling multiple components or parts. Think everything from bicycles to computers. Each assembly process must be carefully planned, tracked, and cost-controlled. Luckily, NetSuite ERP for manufacturing makes this a breeze.

NetSuite offers powerful tools to manage your assembly processes, starting with Bill of Materials (BOM) management. It ensures you have accurate, up-to-date product structures, making it easier to manage work orders, keep track of component availability, and monitor costs effectively.

For companies creating customized or engineer-to-order (ETO) products, NetSuite integrates project management tools to coordinate design, engineering, and production activities seamlessly. Need to track custom quotes or design changes? NetSuite handles this effortlessly, allowing your team to focus on delivering exceptional products without drowning in paperwork.

Similarly, if your operation produces goods according to customer specifications (make-to-order), NetSuite simplifies the entire process by automatically converting sales orders into work orders. It calculates available-to-promise dates accurately, manages configuration complexity, and even supports customer-specific pricing agreements.

High-volume producers aren’t left out either. NetSuite optimizes production scheduling, demand planning, finished goods inventory, and distribution management. In short, it helps you balance efficiency, inventory, and customer satisfaction like a pro.

Process Manufacturing

Unlike discrete manufacturing, process manufacturing involves mixing ingredients or raw materials following specific recipes or formulas—think food, beverages, pharmaceuticals, and cosmetics. Precision here is key, and again, NetSuite can handle it like a seasoned chef.

With NetSuite, you can effortlessly manage your formulas and recipes, including alternative ingredients, scaling batch sizes, and tracking formulation changes over time. Ever experienced the headache of managing batch production? NetSuite provides control over batch numbering, attributes, quality testing, and genealogy—crucial for regulated environments.

Lot tracking and expiration management couldn’t be simpler. NetSuite ensures you use the oldest materials first (First-Expired-First-Out), minimizes waste, and keeps your products safe and fresh. Additionally, it helps process manufacturers optimize yields by providing essential data on planned versus actual yields, valuable by-products, co-product allocations, and yield losses.

To learn more about how NetSuite supports food and beverage manufacturers, explore our detailed guide on NetSuite for food and beverage.

Contract and Outsourced Manufacturing

If your manufacturing strategy involves outsourcing some or all of your production, NetSuite ERP for manufacturing has got your back.

Managing outsourced production is tricky—communication with vendors, monitoring quality, and controlling costs can feel overwhelming. NetSuite simplifies vendor management with tools to track performance, manage vendor certifications, facilitate smooth communication, and evaluate vendor performance using intuitive scorecards.

As one of our clients joked, “NetSuite allows us to manage our outsourced production like they’re just next-door neighbors—even though they’re halfway across the globe!”

NetSuite makes outsourced production transparent by allowing you to track work orders, monitor provided components, and perform quality inspections on received products. Cost management features give you clear insights into contract pricing, total outsourcing costs, and profitability.

Thanks to robust multi-currency and international compliance features, NetSuite effortlessly supports global contract manufacturing relationships. You’ll never have to stress about regulatory compliance or international shipping complexities again.

Whether you’re considering discrete, process, or outsourced manufacturing—or a combination of these models—NetSuite’s best flexibility and features make it an ideal solution. At Nuage, we’ve spent over 20 years guiding manufacturers through their digital change journey and helping them select, implement, and optimize the right ERP solutions. If you’re curious how NetSuite can transform your manufacturing operations, let’s chat!

Explore our dedicated NetSuite ERP for manufacturing page or find alternative solutions—we’re here to help you choose what’s best for your business, not just sell software.

Implementing NetSuite ERP for Manufacturing Success

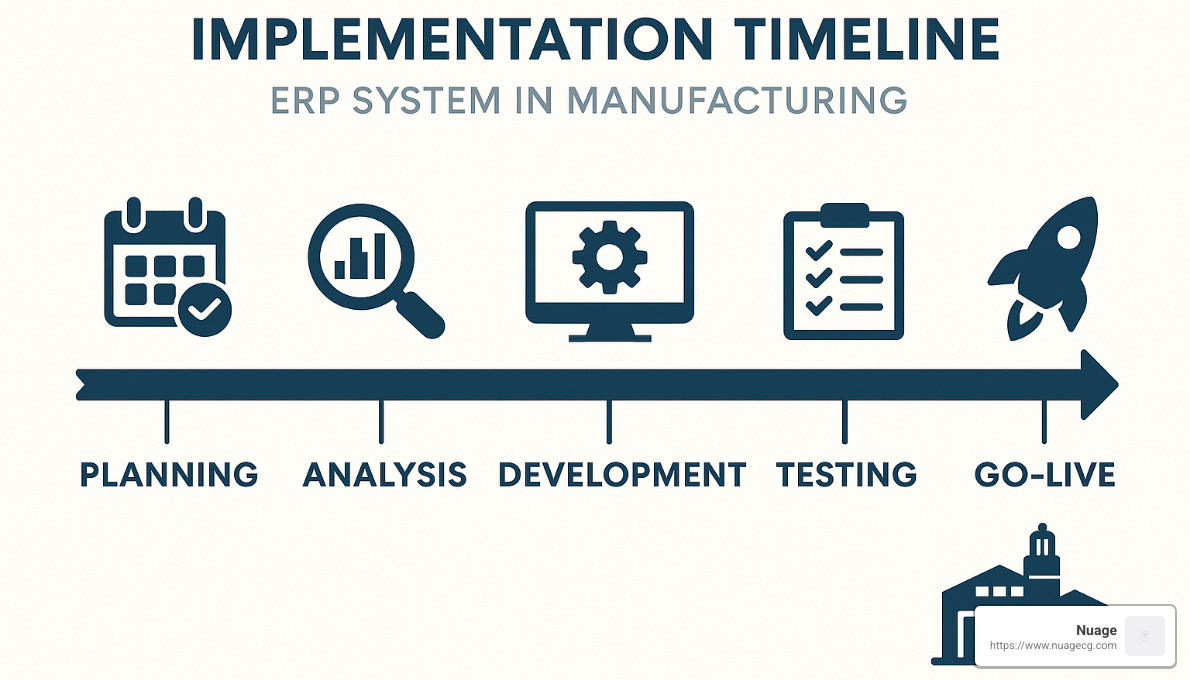

Implementing NetSuite ERP for manufacturing can feel like a big step—but rest assured, the payoff is absolutely worth it. At Nuage, we’ve walked alongside countless manufacturers on this journey. With over 20 years in ERP, we’ve developed a proven approach to make sure your NetSuite implementation is smooth, effective, and custom specifically to your business.

To set yourself up for success, some key considerations are crucial. Let’s explore the core elements that make your NetSuite transition as seamless—and dare we say, enjoyable—as possible.

Key Implementation Considerations

Every successful ERP project begins with clear planning and understanding. Here’s our advice for getting it right from day one:

First, dig deep into your business requirements. Take the time to document exactly how things run today (warts and all!), then carefully outline how you’d ideally like processes to flow in the future. A comprehensive gap analysis—comparing those ideal processes to NetSuite’s standard capabilities—helps you define what’s essential, what’s nice-to-have, and what might need customization.

Next, get your data migration right—trust us, you’ll thank yourself later! We can’t emphasize enough the importance of clean, accurate data. Begin by carefully identifying all data you’ll move into NetSuite. Take the opportunity to tidy things up (goodbye duplicated customer records!), then decide precisely what you’ll migrate, when, and how you’ll validate accuracy post-migration. One of our clients recently shared, “The extra time we spent cleaning our data before migrating made all the difference. We kicked off our NetSuite journey with peace of mind—and pristine data.”

Integration is another biggie. Rarely does a manufacturing ERP live alone. You’ll likely need to connect NetSuite ERP for manufacturing to other key systems—production equipment, warehouse management, quality control software, or even your CRM. Determine early which integrations you’ll require, how they’ll exchange data with NetSuite, and how you’ll continuously monitor integration health. Trust us, smoothly integrated systems are worth their weight in gold.

Finally, never underestimate user adoption. A shiny new system is only valuable if your team actually loves (or at least, doesn’t hate!) using it. Identify key stakeholders, clarify expectations, and create a plan for continuous communication and training. Having strong post-launch support is critical. The better your people understand and accept NetSuite, the quicker you’ll see substantial returns.

Best Practices for NetSuite ERP Implementation

At Nuage, we’re big believers in learning from experience. After countless successful NetSuite ERP for manufacturing rollouts, we’ve gathered a few tried-and-true best practices that help ensure smooth sailing.

Follow a phased implementation approach. Instead of attempting a “Big Bang” rollout, break the implementation into manageable, logical steps. Begin by implementing core functionalities first—like financials, production management, and inventory control—then gradually introduce additional modules or more sophisticated features. For example, start with a pilot group of users or a single location. Once you’re confident, scale out incrementally. Each phase builds on the successes (and lessons!) of the previous one.

Involve a cross-functional team throughout the process. Nothing spells trouble faster than approaching an ERP implementation as “just an IT project.” Establish a project team that includes representatives from finance, production, supply chain, quality control, and more. Clear responsibilities, regular collaboration, and active executive sponsorship ensure that everyone’s voice is heard. Your solution will be more comprehensive, and you’ll have strong buy-in and enthusiasm across your entire organization.

Testing, testing, and yet more testing is non-negotiable. Plan thoroughly, and perform extensive user acceptance testing (UAT) involving real-world scenarios from actual end users. Ensure NetSuite integrates smoothly with existing systems, and rigorously test performance under realistic conditions. When launch day comes, you’ll confidently flip the switch knowing you’ve ironed out any potential wrinkles.

Finally, approach your NetSuite implementation with a continuous improvement mindset. The day you go-live is just the beginning. Regularly seek feedback from users and periodically review system performance. Identify what went well, what could be better, and make adjustments accordingly. A roadmap for ongoing improvements ensures you’re always deriving increasing value from your NetSuite investment.

At Nuage, our experienced consultants partner closely with you throughout your NetSuite journey. From initial planning and data mapping to testing, go-live, and beyond, we’re dedicated to your success. As a trusted partner of NetSuite, our goal isn’t just to install software—we’re here to help you achieve meaningful digital change that sets your manufacturing business up for long-term success.

Ready to learn more about implementing NetSuite for your manufacturing business? Check out our detailed article on choosing the right NetSuite Implementation Consultant or reach out to our friendly Nuage team—we’re here to help every step of the way.

Frequently Asked Questions about NetSuite ERP for Manufacturing

At Nuage, we’ve guided many manufacturing companies through their digital change journeys. When it comes to NetSuite ERP for manufacturing, we often hear similar questions from clients who are evaluating if this solution is right for them. To help you out, we’ve rounded up the top questions we frequently hear—along with clear, honest answers.

How Does NetSuite ERP Differ from Traditional Manufacturing Systems?

Traditional manufacturing systems were typically installed on-site, requiring lots of hardware, IT support, and complex maintenance. NetSuite, on the other hand, is completely cloud-based. This means you don’t need to invest in costly servers or dedicate IT resources to keep the system running. You can access your data securely from anywhere, at any time—making remote work and multi-site management a breeze.

Another significant difference: NetSuite offers fully integrated functionality. No more hopping between separate systems for finance, inventory management, and production. With NetSuite, all your core processes live comfortably under one roof. This gives you one accurate source of truth, eliminating data silos and tedious manual entries.

And speaking of maintenance, here’s a breath of fresh air: NetSuite rolls out automatic updates twice a year, seamlessly delivering new features and improvements without downtime or extra costs. Forget those painful upgrade cycles of older systems!

Finally, scalability is a standout benefit. As your business grows—whether adding new products, opening locations, or entering new markets—NetSuite easily adapts. You won’t outgrow it, and you won’t need disruptive upgrades to keep up.

(For a deeper dive into NetSuite’s strengths, see our NetSuite overview page or explore more directly on NetSuite.com.)

What is the ROI Timeline for NetSuite ERP in Manufacturing?

This is a big one! While every business is different, we’ve found that most manufacturers start seeing tangible returns between 3 to 6 months after going live. Full return on investment typically happens within 12 to 24 months. Of course, your timeline might vary depending on factors like implementation scope, the complexity of current systems, and how quickly your team accepts the new ERP.

Early wins often come from inventory optimization (say goodbye to wasted warehouse space and carrying costs!), increased productivity (fewer errors, less time spent on manual entries), and better visibility into operations and finances (real-time decisions save money).

One client, a mid-sized manufacturer we worked with, recouped their entire NetSuite investment within the first year—just by reducing inventory carrying costs and improving productivity. Talk about a quick win!

How Does NetSuite Support Different Manufacturing Models?

Manufacturing isn’t one-size-fits-all—and neither is NetSuite ERP. Its flexibility is one reason it’s become a favorite across diverse manufacturing models. Let’s quickly explore how NetSuite adapts to various types of manufacturing:

If you’re in discrete manufacturing (think assembling distinct products from components), NetSuite provides strong capabilities like comprehensive Bill of Materials management, detailed work order tracking, component usage monitoring, and precise assembly costing. It’s ideal for manufacturers who need clear visibility across complex assembly processes.

For process manufacturing (that’s you if you’re blending, mixing, or using recipes), NetSuite offers robust formula management, batch production tracking, lot and expiration management, and yield analysis features. Keeping batches consistent and managing expiration dates has never been simpler.

What if you’re doing a bit of both? No worries—NetSuite has you covered with its strong mixed-mode manufacturing capabilities. You can manage discrete assemblies alongside process-driven batches effortlessly, all within a single system.

And what about custom products? Manufacturers doing make-to-order and engineer-to-order get powerful built-in tools for customer-specific pricing, product configurations, project cost tracking, and milestone-based billing. Say goodbye to time-consuming spreadsheets and hello to streamlined project management.

Finally, for make-to-stock operations (high-volume production to fill inventory), NetSuite’s demand planning, production scheduling, and distribution management features help keep shelves appropriately stocked without unnecessary overhead.

For more info on how NetSuite ERP can fit your unique manufacturing model, check out our detailed NetSuite manufacturing overview or explore direct resources at NetSuite.com.

We know making the switch to an ERP system like NetSuite is a big decision. Hopefully, these FAQs clear things up a bit—or at least get you started! Still have questions? No worries. Our warm and friendly Nuage team has 20+ years of ERP experience, and we’re always here to help you determine the best solution for your manufacturing business—whether that’s NetSuite or something else.

Reach out anytime. We’ve got your back.

Conclusion

Navigating today’s rapidly evolving manufacturing world is no small feat. The pace of change, from unpredictable supply chains to rising customer expectations, is enough to keep even the most seasoned manufacturer awake at night. Thankfully, having the right technology partner by your side can transform these challenges into opportunities for growth and innovation. At Nuage, we’ve witnessed how NetSuite ERP for manufacturing can be a game-changer for modern manufacturers—delivering the flexibility, visibility, and efficiency needed not just to survive, but thrive.

Throughout this guide, we’ve explored how NetSuite ERP for manufacturing empowers companies to tackle today’s biggest problems head-on. Supply chain disruptions become manageable with real-time visibility across inventory and suppliers. Labor shortages become less daunting thanks to intuitive user interfaces and automation that boost team productivity. Capacity planning headaches ease up with powerful scheduling tools and insightful analytics—helping you make smarter resource decisions every day.

Keeping up with strict quality and compliance demands? NetSuite integrates robust quality management right into your processes, streamlining inspections and audits, and giving you peace of mind. And when global competition heats up, features like multi-currency, multi-language, and multi-subsidiary support give you a clear edge. NetSuite helps manufacturers operate seamlessly on a global scale, ensuring you’re always a step ahead.

We also dug deeper into the core features that make NetSuite ERP for manufacturing such an essential tool today. From comprehensive production management and real-time shop floor control to advanced inventory optimization, NetSuite has you covered. Detailed financial management and insightful reporting capabilities mean you’ll always stay on top of your bottom line. When it comes to quality control and industry compliance, NetSuite simplifies complex tasks, helping you consistently meet customer expectations and regulatory requirements without breaking a sweat.

At Nuage, we understand that every manufacturer’s journey is unique. With over 20 years of experience in ERP implementations, our passionate team takes pride in tailoring solutions to meet your specific needs. Our goal isn’t just to sell you software—it’s to help you choose the right solution, carefully steer the implementation process, and continually optimize your ERP for maximum value. Whether you’re considering NetSuite ERP or exploring other options, our experts have your back every step of the way.

Manufacturing is changing fast—and it won’t slow down anytime soon. But that’s not a reason to worry. With the right digital foundation in place, these changes become opportunities for growth, efficiency, and competitive advantage. NetSuite ERP for manufacturing provides exactly that foundation: scalable, flexible, and powerful enough to keep you agile and future-ready.

Interested in learning more? Find the possibilities by visiting NetSuite’s manufacturing industry page, or take your next step with our easy-to-understand NetSuite 101 guide. Want personalized advice? Our friendly team at Nuage would love to help—just let us know how we can support your manufacturing goals.

Together, let’s transform your manufacturing operations and build a future-ready business.