Why Food Industry Digital Change is Crucial for Your Business

Food industry digital change refers to integrating digital technologies like cloud ERP systems, AI-driven analytics, IoT, and automation throughout food production, management, and distribution processes. It’s used to increase operational efficiency, improve safety and compliance, drive cost reductions, and improve the customer experience. In short, digital change helps food businesses stay competitive, resilient, and aligned with evolving consumer demands and regulatory requirements.

Here’s the quick answer for those who just need the highlights:

- What it is: Using tech such as ERP solutions, IoT, automation, and analytics in the food industry.

- Why it matters: Boosts efficiency, saves money, improves product quality and safety, and provides better consumer experiences.

- Main Benefits: Operational improvements, better compliance, higher profitability, supply chain resilience, and improved consumer trust.

- Key Technologies: Cloud ERP (NetSuite), IoT sensors, AI analytics, robotics, predictive maintenance tools.

I’m Louis Balla, CRO and partner at Nuage, with over 15 years of experience in digital change and supply chain solutions. I’ve specialized in ERP platforms, notably NetSuite, helping numerous food manufacturers successfully implement their Food industry digital change projects.

Glossary for Food industry digital change:

– ERP solutions for food

– ERP solutions for manufacturing

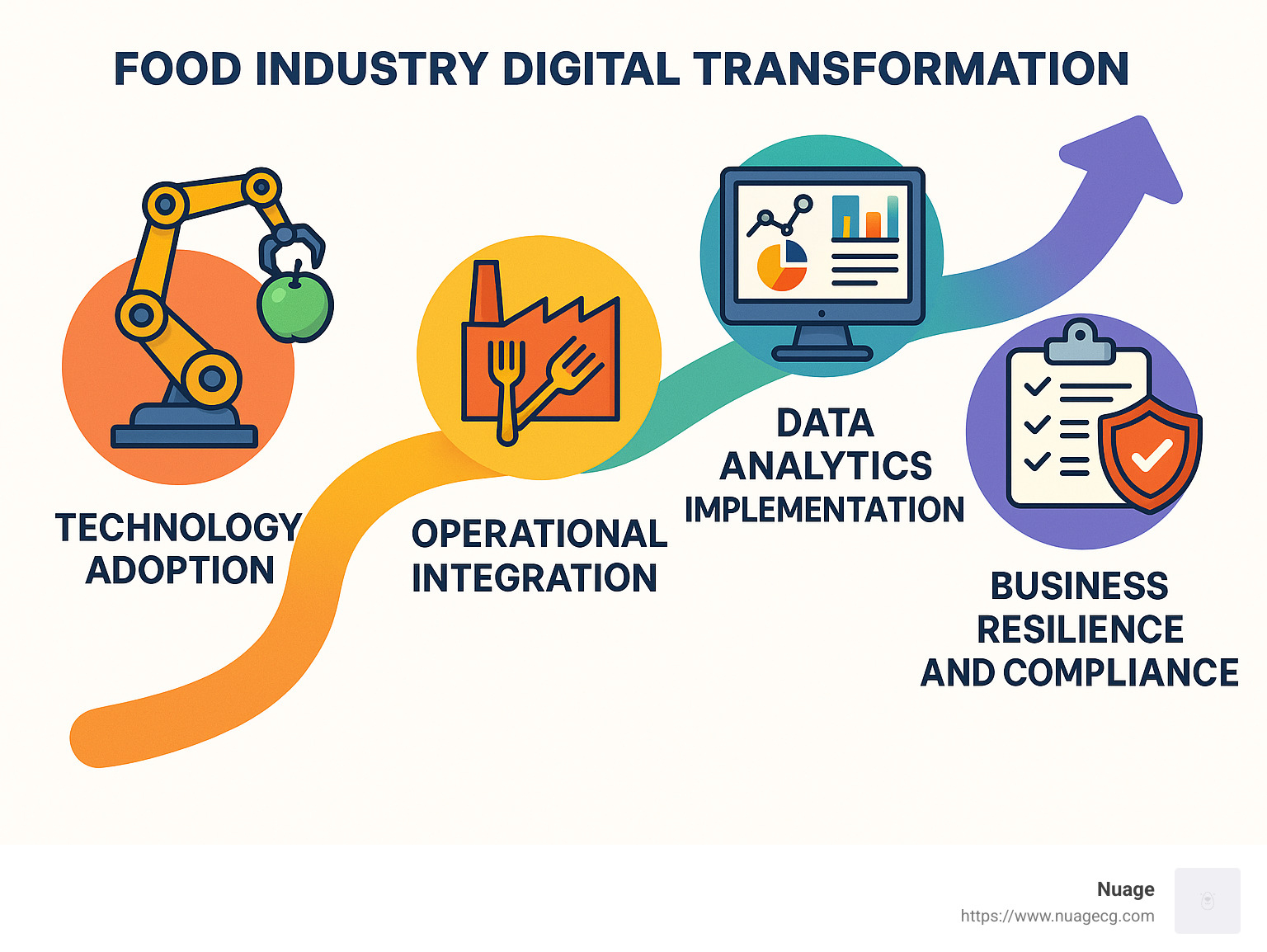

Understanding Food Industry Digital Change

The food and beverage world is changing fast, and technology is leading the charge. Food industry digital change isn’t just about fancy new gadgets—it’s about reimagining how your entire operation works in today’s connected world.

Think of modern ERP systems like NetSuite as the brain of this operation. They connect everything—from the ingredients coming in your door to the products going out to customers—in one central hub. And because they’re cloud-based, you can access your business info from anywhere, anytime.

The results speak for themselves. According to IDC research, three-quarters of food and beverage leaders report better performance across their businesses after embracing digital technologies. That’s real impact you can measure!

Smart sensors (IoT devices) are now keeping watch over your production lines, tracking temperatures, humidity, and other critical factors in real-time. All this data feeds into analytics tools that help you spot trends and make smarter decisions.

As we’ve seen while helping clients implement ERP for Food and Beverage Industry solutions, the right system dramatically cuts down on manual errors, improves record accuracy, and helps you respond faster in this market.

The Driving Forces Behind Digital Change in Food

Several powerful forces are pushing food industry digital change forward faster than ever:

Today’s consumers want to know everything about their food—where it came from, what’s in it, and how sustainable it is. Digital tools help you provide this transparency and build trust with your customers.

Regulations like the Food Safety Modernization Act have shifted from “react to problems” to “prevent problems before they happen.” Digital systems automate compliance checks and documentation, keeping you on the right side of regulators.

Going green isn’t just good PR—it’s good business. McKinsey reports that companies with advanced digital strategies cut their environmental footprint dramatically—reducing greenhouse gases, waste, water and energy use by up to half in some cases.

In an industry where profit margins are often razor-thin, efficiency is everything. Automation and AI-powered tools help you reduce waste, keep equipment running, and make the most of every resource.

When your competitors adopt these technologies and gain an edge, you need to keep pace. This creates a positive cycle where everyone in the industry keeps improving.

And let’s face it—finding and keeping good workers is tough these days. Digital tools can help bridge the gap by streamlining operations and reducing dependence on manual labor.

Key Technologies Reshaping the Food Industry

The technology reshaping food production and distribution is evolving rapidly. Here are the game-changers:

Artificial Intelligence and Machine Learning are like having a crystal ball for your business. They analyze patterns in your data to predict equipment failures before they happen, forecast demand more accurately, and spot quality issues that human eyes might miss.

Blockchain technology creates an unalterable record of your food’s journey from farm to table. If there’s ever a safety concern, you can trace products to their source in minutes instead of days, potentially saving lives and your reputation.

IoT Sensors act as your eyes and ears throughout production and distribution. They constantly monitor critical conditions like temperature and humidity, helping maintain quality and reduce waste.

Cloud-Based ERP Systems like NetSuite for Food and Beverage bring everything together in one place. From purchasing ingredients to shipping finished products, these platforms keep your entire operation running smoothly and in compliance.

Robotics and Automation are booming in food production—expected to grow by 5.4 billion units by 2030. Robots handle repetitive tasks like sorting, cutting, and packaging with perfect consistency, freeing up your human talent for more complex work.

Predictive Analytics helps you see around corners. By analyzing historical data, you can anticipate equipment failures, forecast demand spikes, and keep just the right amount of inventory on hand.

At Nuage, we’ve guided countless food businesses through this technological evolution. We don’t just sell software—we help you find the right mix of tools to solve your specific challenges. The key is starting with your business goals, then finding the technology that gets you there—not the other way around.

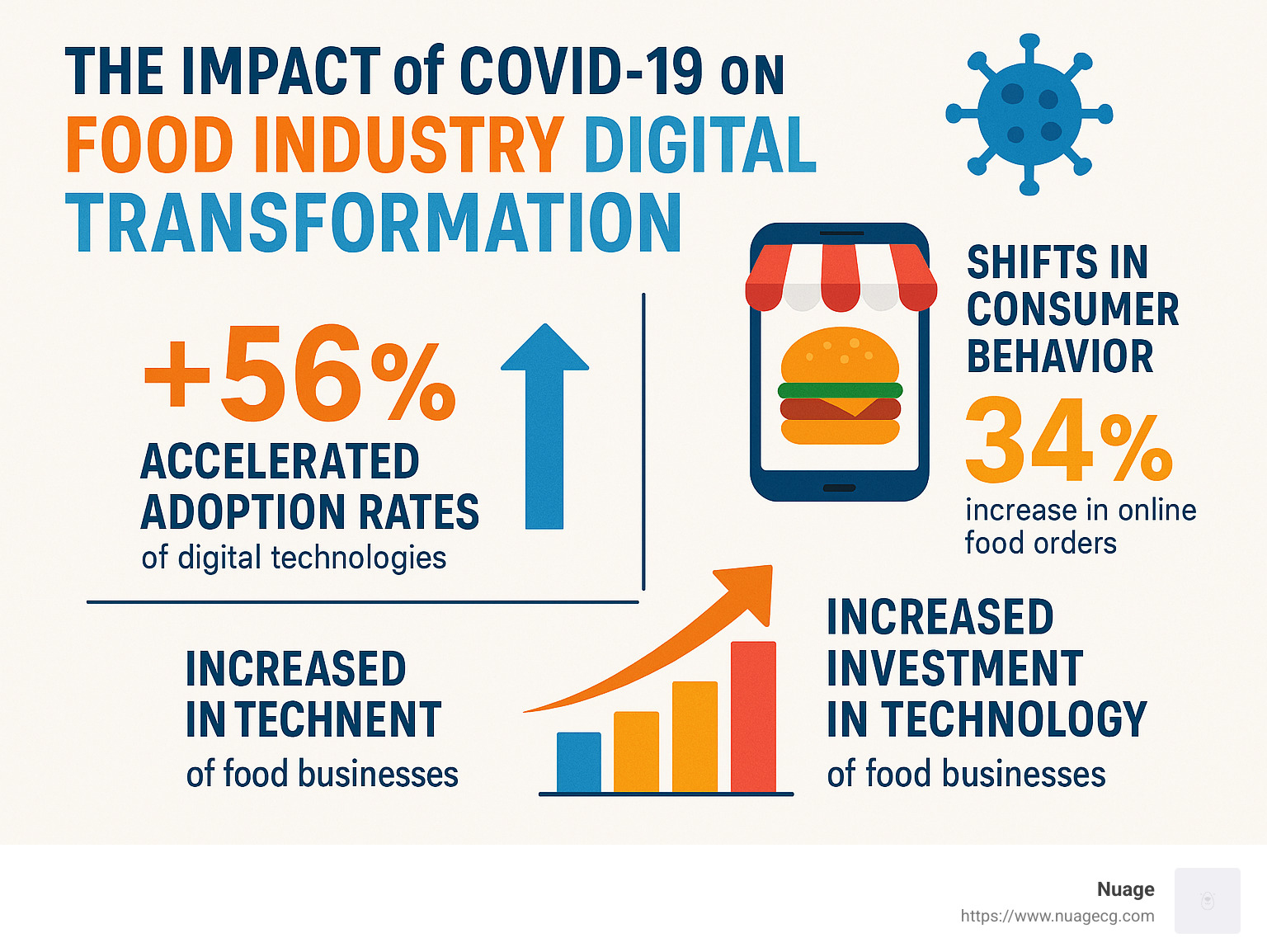

The Impact of COVID-19 on Food Industry Digital Change

When COVID-19 hit, it didn’t just change our personal lives—it completely transformed how food companies operate. What might have taken years to implement suddenly happened in a matter of months. The pandemic wasn’t just a disruption; it was a wake-up call that pushed food industry digital change into overdrive.

I’ve seen how companies that had been hesitant about new technology suddenly couldn’t implement it fast enough. When nearly 70% of food and beverage businesses reported major supply chain disruptions, it became crystal clear that the old ways of doing business just weren’t going to cut it anymore.

Remember those early pandemic days? Empty store shelves, restaurant closures, and consumers panic-buying pasta and toilet paper. Companies with digital systems already in place could pivot quickly—adjusting production, rerouting deliveries, and keeping customers informed. Those relying on manual processes and in-person interactions? They struggled to keep up.

As we explain in our Digital Change for Manufacturers: A Step-by-Step Guide, the pandemic forced businesses to not just address immediate challenges but also build long-term resilience. Many of our clients at Nuage found themselves accelerating digital projects that had been on the back burner for years.

How Food Companies Responded to the Pandemic

The pandemic response in the food industry wasn’t just impressive—it was inspiring. Companies that had never considered e-commerce suddenly built online stores. Manufacturers who relied on distributors found ways to ship directly to consumers’ homes. The creativity and adaptability were remarkable.

Omnichannel strategies became essential overnight. Local bakeries started offering online ordering. Meat processors created consumer-friendly packaging. Restaurant suppliers pivoted to serve home cooks. Companies that implemented NetSuite found they could quickly add these new channels without rebuilding their entire business systems.

Direct-to-consumer models flourished as traditional distribution channels faltered. When restaurants closed, food manufacturers needed new ways to sell their products. Many launched their own online stores, creating new revenue streams that continue today, long after restaurants reopened.

Automation initiatives accelerated dramatically as companies dealt with labor shortages and social distancing requirements. From robotic process automation handling paperwork to actual robots on production lines, technology stepped in when human hands couldn’t.

Virtual inspections became the norm as regulatory agencies and quality teams adapted to travel restrictions. Food safety couldn’t take a backseat to the pandemic, so companies implemented remote monitoring systems and video-based inspections to maintain standards.

Contactless operations transformed overnight from a convenience to a necessity. Digital payment systems, QR code menus, and contactless delivery became standard features rather than premium options.

As one of our food industry clients told me: “Faced with challenges on all fronts, food companies stepped up their digital change efforts. They focused on optimizing their processes for maximum efficiency and building resiliency into their supply chains.”

Perhaps the most significant shift was toward cloud-based solutions. When offices closed and staff worked from home, on-premise systems became a liability. According to recent industry surveys, about 25% of food and beverage companies have already moved their ERP to the cloud or are in the process of doing so, with another quarter actively exploring the option.

At Nuage, we’ve helped numerous food companies steer this challenging transition, implementing flexible NetSuite solutions that enable remote work while maintaining security and compliance. The pandemic may have forced their hand, but many of our clients now say they wish they’d made the move sooner.

The silver lining? These rapid changes have positioned food companies to be more resilient, efficient, and customer-focused than ever before. What started as crisis response has evolved into strategic advantage. The food industry digital change that COVID-19 accelerated isn’t slowing down—it’s becoming the new standard for success in a post-pandemic world.

Benefits of Digital Change in the Food Industry

Embracing food industry digital change isn’t just about upgrading technology—it’s about open uping real, measurable benefits that directly boost your business’s bottom line, improve safety, and lift customer satisfaction. Let’s break down these advantages into clear, digestible (pun totally intended!) insights.

Operational Efficiency and Cost Reduction

When margins are tight—as they often are in food manufacturing—every efficiency counts. Digital technologies offer powerful ways to streamline operations and lower costs at every step of the process.

For starters, automated workflows eliminate those tedious manual tasks and paperwork, freeing your team to focus on more valuable activities. In fact, smaller food manufacturers who’ve incorporated modern ERP solutions, like NetSuite, have reported operating cost reductions averaging around 11%. Imagine what you could do with that extra margin!

Technology like IoT sensors also enables predictive maintenance, which spots equipment issues before they become costly breakdowns. One food business leveraging predictive maintenance tech saw a significant 20% reduction in unexpected downtime—pretty impressive, right?

Goodbye guesswork—hello, optimal inventory. By implementing advanced analytics through cloud-based ERP platforms, food companies can achieve inventory optimization, meaning less money tied up in excess stock and fewer out-of-stock headaches. NetSuite is particularly strong in this area, offering features tailored to the specific needs of the food industry.

Moreover, digital monitoring identifies areas of waste reduction you might otherwise overlook. Some companies have achieved up to 20% less waste by tracking operations digitally and pinpointing inefficiencies—saving both money and the environment.

Speaking of sustainability, energy efficiency is another key advantage. Digital sensors monitor and optimize energy usage, reducing utility bills and carbon footprints simultaneously. One food processing facility in France, for example, cut their energy use and emissions by 25% simply by implementing IoT sensors and cloud analytics.

Finally, digital tools significantly boost labor productivity. Streamlining tasks and improving access to real-time information means your staff spends less time chasing details and more time actually moving the business forward. Our Food Distribution ERP guide highlights how the right ERP system can notably improve productivity across distribution operations.

Improved Food Safety and Compliance

In the food industry, safety isn’t optional—it’s essential. Thankfully, digital change provides powerful tools to ensure food safety and regulatory compliance with ease.

Real-time data collection via IoT sensors allows for continuous monitoring of your operations’ critical control points. This proactive approach reduces risks and helps catch potential issues long before they become serious problems.

Automated digital platforms also handle compliance checks seamlessly, verifying each process against regulatory standards without manual intervention. With regulations increasingly complex and strict—such as the Food Safety Modernization Act—this efficiency is a huge advantage.

End-to-end digital solutions offer complete traceability, documenting the journey of ingredients and finished products from farm to fork. This transparency means that, should a recall occur, you can quickly identify the exact source, dramatically limiting scope and impact. Smart allergen management features further mitigate risks of cross-contamination, protecting both consumers and your brand reputation.

And when recalls do happen, digital platforms enable quick, precise responses. Companies equipped with strong traceability and recall systems can often isolate incidents to specific batches, minimizing disruption and preserving consumer trust.

Documentation and compliance record-keeping also become effortless with digital platforms, eliminating cumbersome paper-based processes. Solutions such as ERP for Food Manufacturing illustrate how streamlined digital documentation significantly reduces administrative burdens, allowing you to focus more on the core of your business.

Improved Customer Experience and Engagement

Digital change doesn’t just streamline operations—it also transforms the way your customers experience your brand.

It all starts with personalization. Digital platforms and analytics help you deeply understand your customers’ preferences, enabling custom marketing, customized product recommendations, and personalized promotions. This creates stronger connections and builds long-term loyalty.

Consumers nowadays also demand greater transparency. Digital tools empower you to easily share detailed information about your products—ingredients, sourcing, nutritional values, and sustainable practices—right at consumers’ fingertips. Something as simple as a QR code on packaging can offer a wealth of information, building trust with every scan.

An integrated digital presence facilitates a smooth omnichannel experience, allowing customers to easily interact with you in-store, online, or through mobile devices. By meeting consumers where they are, you make it easier (and more enjoyable!) for them to engage with your brand.

Additionally, digital tools help present comprehensive product information clearly and conveniently. This includes allergen data, nutrition facts, and preparation instructions, ensuring customers have everything they need to make informed choices.

Flexible delivery options—such as home delivery, click-and-collect, and subscription models—are easily enabled by digital platforms. These features boost convenience and encourage repeat purchases, enhancing customer satisfaction and loyalty.

Finally, digital channels establish continuous feedback loops, allowing your customers to effortlessly share their insights. This means you can quickly respond, adapt, and innovate based on real-world responses, creating a genuinely customer-centric approach.

From operational efficiency and cost savings, to better compliance, improved product safety, and an outstanding customer experience—food industry digital change truly offers tremendous potential. With Nuage’s expertise in ERP solutions like NetSuite, you’re in great hands to reap these benefits and drive lasting success.

Implementing Digital Change in the Food Industry: A Step-by-Step Approach

Successfully navigating food industry digital change isn’t something that happens overnight. It’s a thoughtful journey—a series of well-planned steps that involve people as much as they involve technology. To help you on your way, we’ve developed a clear and friendly roadmap that outlines exactly how to tackle digital change in your food and beverage business.

Step 1: Assess Your Current State and Define Objectives

Before diving headfirst into digital change, take a step back to understand where you currently stand. This first step sets the foundation for everything that comes after.

Begin by conducting a gap analysis to honestly evaluate your current systems and processes. Identify what’s working well—and where there’s room for improvement. Clearly define your business goals, making sure they’re SMART (specific, measurable, achievable, relevant, and time-bound).

Next, take a close look at your organization’s biggest pain points. Where are you feeling the most pinch? Perhaps it’s slow order processing, outdated inventory tracking, or difficulty complying with regulations. Pinpointing these challenges early on will help you prioritize effectively.

It’s also wise to benchmark your business against competitors. Understanding how others in your industry are handling digital change can highlight areas where you might be falling behind—or give you ideas on how to leap ahead.

Don’t forget to gather input from stakeholders across your organization, from leadership down to frontline employees. Their real-world insights will reveal practical opportunities (and challenges) you might not have otherwise considered. Finally, prioritize initiatives based on their potential impact and feasibility, and clearly define success metrics to track your progress.

Step 2: Select the Right Technologies and Partners

With clear objectives and priorities in place, you’re ready to choose the best-fit technologies—and partners—to help you achieve your goals. For many food companies, a modern ERP system is the heart of digital change, offering centralized control and visibility. Industry-leading ERP solutions like NetSuite offer powerful, cloud-based ERP solutions custom specifically for food and beverage businesses.

As you evaluate software options, ensure they have strong integration capabilities so they talk seamlessly with your existing systems, like warehouse management, transportation software, or customer platforms. Also, think long-term: prioritize solutions that offer easy scalability, adaptability, and regular updates, like those provided through the NetSuite Solution Provider Program.

Don’t underestimate the value of industry expertise in your technology partner. At Nuage, for instance, we’ve spent more than 20 years guiding food and beverage companies through their digital change journeys. We don’t just sell software—we help you select the right solutions and make sure they work effectively in your unique environment.

Consider carefully the level of implementation support and training resources offered by technology providers. Thorough training is critical to ensuring your teams accept and effectively use new systems. Finally, understand the total cost of ownership—including implementation, training, maintenance, and upgrades—to avoid surprises down the road.

Step 3: Develop a Phased Implementation Plan

Digital change isn’t a sprint; it’s a marathon (but far less sweaty). A phased approach helps reduce risk, ensures smoother adoption, and sets you up for early wins.

Start by identifying quick wins: projects that have high impact but lower risk, so you can build momentum and confidence within your team. Launch pilot projects in controlled environments, allowing you to test, learn, and make necessary adjustments before rolling out broadly. Always have a solid risk management strategy in place, preparing you for potential setbacks.

Resource allocation is crucial. You wouldn’t bake a cake without gathering all your ingredients first—similarly, make sure you have the budget, personnel, and time required for successful implementation. Develop a clear, detailed timeline that includes planning, configuration, training, testing, and go-live—building in some buffer for unexpected hiccups.

Good communication is key. Keep your team in the loop at every step, managing expectations and building excitement about the positive changes ahead. Lastly, have contingency plans ready. Life happens, so it’s wise to have fallback procedures in place if you encounter any issues during implementation.

Step 4: Manage Change and Train Your Workforce

Here’s a secret: the most challenging (and rewarding!) aspect of digital change is usually the human element. After all, technology doesn’t operate itself—your people are what truly make digital change successful.

Begin by securing strong leadership buy-in. Leaders at all levels must actively champion the change, demonstrating commitment and enthusiasm. Engage your employees early and often, asking for their input and feedback. Allowing them to shape the process builds ownership and reduces resistance.

Invest heavily in skills development. Continuous, practical training helps your team become proficient with new technologies and processes. Clear, user-friendly documentation of new procedures is also invaluable—think of it as a helpful manual for your staff.

Encourage continuous feedback through clear channels. Quick feedback loops help you identify and fix issues promptly. Provide performance support resources, such as help desks, FAQs, or peer support teams, so your staff have help available when they need it most.

Embracing digital change often means embracing a new culture—one of innovation, continuous improvement, and data-driven decision-making. Celebrate successes loudly and often, reinforcing the positive impact digital change has on your business.

Step 5: Measure Results and Continuously Improve

Digital change in the food industry isn’t a single event—it’s an ongoing journey. Once you’re up and running, continue tracking key performance indicators (KPIs) regularly to measure your progress and success.

Leverage the powerful data generated by your new systems to gain deeper insights. Analyze what’s working, what’s not, and what needs optimization. Continuously gather user feedback, too. Your team members on the front lines will have invaluable insights into how systems are performing in real-world scenarios.

Regularly optimize your system configuration and keep pace with technology updates. Cloud-based platforms like NetSuite automatically deliver new improvements, keeping your capabilities fresh and current.

Refine processes regularly based on your learnings, ensuring you continue to get the most from your digital investment. And don’t stop looking ahead—stay curious and keep an eye on emerging technologies. Maintain an innovation pipeline, testing and preparing for future opportunities that can further propel your business forward.

In the end, digital change is about continuous improvement. It’s not just a tech upgrade; it’s a strategic shift that transforms your entire food business, positioning it for long-term success, resilience, and growth.

Real-World Success Stories of Food Industry Digital Change

When it comes to food industry digital change, seeing really is believing. Real-world success stories aren’t just impressive—they’re inspiring. Let’s take a closer look at how digital technologies are reshaping the food industry, making life easier, production smoother, and customers happier.

Case Study: Bakery Digitizes Sales Operations

Imagine you’re a bakery supplying delicious baked goods across several countries. Sounds tasty, right? But behind the scenes, the sales and ordering processes were anything but sweet. Manual order handling was slow, prone to errors, and left customers feeling a bit neglected. “With all the requirements coming in, we were feeling quite uncomfortable with the level of responsiveness we could currently provide,” confessed their Digital Lead.

To tackle these challenges, the bakery acceptd a **cloud-based ERP solution**, migrating their sales operations online, and even launching a B2B e-commerce platform across multiple countries. They integrated seamlessly with retail customers’ systems, allowing for quicker order processing and eliminating manual headaches. Now, employees had real-time visibility of inventory across all their production and distribution points.

The change was nothing short of incredible. The VP of Operations proudly noted, “The most drastic improvement derived from our digital solutions is that we know the inventory situation at any point in time without manual intervention.” With digital tools in place, their B2B e-commerce channel now effortlessly processes large daily orders, significantly improving service and boosting customer satisfaction. Now that’s a recipe for success!

Case Study: Global Producer Improves Supply Chain Visibility

Supply chains can be tricky, especially if you’re a global food producer navigating disruptions like COVID-19. When logistics get complicated, visibility is key. One global food producer found themselves in exactly that situation—struggling to keep products moving and customers informed.

To solve this, they implemented a comprehensive digital solution using tools like predictive analytics, real-time shipment tracking, and integrated inventory management—powered by reliable ERP platforms. They also adopted collaboration platforms to communicate effectively with suppliers, ensuring everyone stayed coordinated and agile.

This digital leap paid off massively. When disruptions hit, the company could quickly reroute shipments, adjust production schedules, and inform customers proactively. And as a bonus, optimized routes and inventory levels even aligned nicely with their sustainability goals, minimizing waste and environmental impact.

In short, digital change didn’t just keep things moving during tough times—it actually improved the company’s resilience and gave them the agility they needed to thrive.

Case Study: Food Manufacturer Implements AI for Quality Control

Quality control can make or break a food manufacturer, and maintaining consistency isn’t always easy. One manufacturer was struggling with inconsistent products, leading to wasted materials and unhappy customers. That’s when they decided to get smart—literally—by implementing an AI-powered quality control system.

They integrated computer vision and machine learning to quickly detect defects right on the production line in real-time. The AI learned quickly, continuously improving its accuracy and helping the equipment automatically adjust as needed. Better yet, all quality checks and data were automatically documented, simplifying compliance and regulatory paperwork.

The results were remarkable: the manufacturer saw a 17% reduction in waste and a 25% boost in product consistency. The AI noticed subtle quality issues humans might have missed, meaning only top-quality products reached customers. “The data we collect in our quality system totally guides our purchasing and manufacturing processes,” said the company’s quality manager. Talk about working smarter, not harder!

These success stories tell a clear tale: food industry digital change isn’t just a tech trend—it’s a proven path to operational efficiency, happier customers, and a healthier bottom line. Whether you’re looking to streamline sales operations, gain end-to-end supply chain visibility, or boost quality with AI, companies like Nuage are here to help. With our deep expertise in NetSuite, we can find the right solutions to make your digital journey a success.

Challenges and Solutions in Food Industry Digital Change

Starting on a food industry digital change journey offers huge benefits, but let’s be honest—it’s not always a walk in the park. Every digital leap forward comes with its share of technical headaches and people-related hiccups. The good news? Understanding these challenges upfront makes overcoming them significantly easier.

Overcoming Technical Challenges

Technical roadblocks are common when shifting to digital, especially in the food and beverage industry where legacy systems seem to stick around way past their expiration dates.

One big hurdle is system integration. Many food businesses run on multiple systems that don’t play nicely together. Think of it as trying to make a recipe when none of your ingredients match. The ideal solution: choose a comprehensive and flexible ERP system like NetSuite that can replace a jumble of outdated systems. Alternatively, middleware or integration platforms can bridge gaps between existing applications.

Then there’s data standardization. Different systems often speak different languages, causing confusion when it’s time to analyze results or run reports. Implementing solid data governance guidelines that define uniform data formats and ensure everyone’s on the same page can save your team from serious frustration down the road.

Infrastructure limitations are another common bump in the road. Older IT setups often struggle to handle modern digital technologies. Moving to the cloud can solve this neatly, reducing reliance on outdated hardware and simplifying maintenance. (Cloud-based ERPs like NetSuite make infrastructure worries a thing of the past.)

Of course, with new tech comes new risks, particularly around security. Digital change expands your digital footprint, making cybersecurity more critical than ever. To stay secure, adopt robust security practices from the start—like encryption, strict access controls, and regular security checks. After all, nobody wants their food secrets leaked online.

Scalability is another consideration. Systems that run smoothly when you’re small may sputter as you grow. Opting for cloud-based solutions (hello again, NetSuite) means your tech can effortlessly scale alongside your business.

And let’s not forget technology obsolescence—today’s shiny tech might be tomorrow’s antique. Choosing modular, regularly updated systems that evolve over time ensures your investment stays relevant. Over 85% of food and beverage instruments already have digital capabilities lying dormant. Leveraging existing tech before adding new ones can maximize your investment and reduce headaches.

Addressing Organizational and Cultural Barriers

But here’s a little secret: the biggest challenges in digital change usually aren’t technical—they’re human.

At the heart of most digital change struggles is plain old change management. Let’s face it, people naturally resist change (we’ve all met someone who’s still using a flip phone). To win buy-in across your organization, implement clear communication, plenty of training, and incentives that encourage adoption. Everyone likes recognition, especially when stepping out of their comfort zones.

Strong, visible leadership commitment is crucial. Executives who champion your digital initiatives and are accountable for results inspire confidence throughout your team. Digital change starts at the top, so make sure your leaders aren’t just on board—they’re steering the ship.

Another common pitfall is underestimating employee training. Tossing new tech at your team without proper support is like handing someone a complicated recipe without instructions. Comprehensive training should cover not just how software works, but why it matters to employees in their roles.

Digital change isn’t just about shiny new systems—sometimes it requires process redesign. Digitizing inefficient processes won’t magically make them effective. Use the opportunity to streamline workflows for maximum efficiency and customer value.

And speaking of motivating people, don’t forget to update performance incentives. If your team is still measured the old-fashioned way, they’ll stick to old-fashioned methods. Adjust your KPIs and reward structures to reflect and encourage digital-forward behaviors.

Lastly, keep enthusiasm high by celebrating early successes. Publicly recognizing small wins builds momentum, reinforces the benefits, and keeps your team energized for the bigger changes ahead. Nearly 70% of industrial firms stall out at the pilot stage of their digital change — a sobering reminder of just how important these people-focused strategies are.

The digital shift in the food industry is an exciting, transformative journey—one that we at Nuage have helped many manufacturing and food businesses steer successfully. Whether you’re exploring solutions like NetSuite or looking for guidance on the best fit for your operations, we’re here to make sure your change is as smooth—and tasty—as possible.

Future Trends in Food Industry Digital Change

The food industry digital change journey is just getting started. Emerging technologies promise exciting possibilities, reshaping everything from production and packaging to customer experiences and sustainability efforts. Let’s explore some of the most promising digital trends on the horizon, and what they mean for food and beverage businesses.

Emerging Technologies to Watch

One of the most captivating technologies making waves right now is Generative AI. Think about having a conversation with your favorite supermarket’s website or app, getting personalized meal recommendations, nutritional advice custom to your diet, or even recipe ideas based on what’s currently in your fridge. According to recent studies, nearly one in four U.K. consumers who’ve tried generative AI would happily use it to improve their food shopping experiences. Expect to see more interactive, personalized experiences driven by this exciting tech.

Another game-changer is the adoption of Blockchain Traceability. This technology has moved beyond the hype stage into practical applications. Blockchain can track food products from farm to fork, allowing for complete transparency. Imagine scanning a QR code on your fresh veggies and instantly seeing where they were grown and how sustainably they were sourced. This isn’t just good for consumers—it also simplifies compliance and recall processes, protecting brands and customers alike.

If you dream of automated production lines humming along seamlessly, you’re not alone. Autonomous Operations powered by robotics and AI are becoming increasingly viable. Fully automated warehouses and production facilities can reduce reliance on manual labor, improve product consistency, and boost overall efficiency.

Smart Packaging is another exciting frontier. Thanks to embedded sensors and scannable QR codes, packaging can now communicate directly with consumers. It could verify authenticity, provide detailed nutritional and allergen information, or even indicate freshness levels. That means no more guessing whether your milk is still good—your packaging might soon tell you directly!

Personalized Nutrition, powered by digital health tracking and data analytics, is gaining serious traction. Digital technologies can pinpoint nutritional recommendations based on individual health data, preferences, and life goals. Imagine personalized food products custom precisely to your unique dietary needs—this reality is closer than you may think.

We’re also seeing fascinating advancements in Vertical Farming, driven by digitally controlled environments. This technology allows fresh produce to be grown sustainably in urban areas, reducing transportation needs and emissions, and providing local communities with fresh food, year-round.

On the more futuristic front, technologies like 3D Food Printing and Cultured Meat Production are gaining momentum. 3D food printing enables customized meals with precise nutritional values, while cultured meat technology aims to sustainably replicate real meat without traditional animal agriculture. Both promise significant sustainability benefits and new market opportunities.

Additionally, Drone Delivery might soon drop fresh groceries right at your doorstep, especially in rural or congested urban areas. And with Voice Commerce, you’ll soon simply tell your smart speaker, “Hey, order more coffee beans,” and they’ll magically appear on your doorstep. Convenience, anyone?

These digital innovations aren’t just speculative—they’re actively shaping the food industry’s future.

Preparing for the Future of Food

So, how can your business get ready for this brave new world?

First, adopt an agile approach. The technology landscape evolves rapidly, so flexibly adapting your strategies as new opportunities emerge is key. Staying nimble means you’ll thrive, not just survive.

Next, foster an innovation-friendly company culture. Encourage experimentation, accept trial-and-error, and celebrate bold ideas. The most successful food businesses aren’t afraid to test new concepts and pivot quickly based on results.

Another practical step is to create ecosystem partnerships. Collaborate with technology providers, research institutes, and even industry peers to share insights. At Nuage, we’ve seen how partnerships between food businesses and technology providers like NetSuite can drive rapid innovation and long-term success.

Don’t forget the people side of the equation. Invest in talent development by hiring digitally savvy team members and continuously upskilling your existing workforce. The future food industry won’t just be about tech—it needs skilled, adaptable people to leverage these innovations effectively.

Engage proactively with regulatory bodies, too. By joining the conversation early, you can help shape regulations that balance innovation and consumer safety. Additionally, take time to educate your consumers about new technologies. Clear communication helps your customers feel confident and informed—and builds trust in your brand.

Finally, remain laser-focused on sustainability initiatives. Digital technologies can dramatically reduce waste, lower energy use, and minimize your environmental footprint. For consumers and regulators alike, sustainability isn’t optional—it’s fundamental.

As Darren Thomson, Senior Client Partner in Consumer Products, puts it: “Everyone defines omnichannel differently, and it’s incredibly complex for food and beverage brands. But fundamentally the best approach to existing and emerging channels is to focus on the customer or consumer need, at any given point of time, and ensure the unified brand experience is available to them.”

In short, while technology trends are exciting, keeping the customer—and the planet—at the heart of your food industry digital change efforts is what will truly set you up for success.

Frequently Asked Questions about Food Industry Digital Change

What are the primary areas of digital change in the food industry?

When we talk about food industry digital change, we’re looking at several connected areas that together reshape how food businesses operate. At the heart of these changes is supply chain management, which benefits from improved visibility, traceability, and greater efficiency from farm to table. From sourcing ingredients to delivering products to customers, digital solutions like cloud ERP platforms (NetSuite) give businesses real-time data to make smarter, quicker decisions.

Another primary focus is food safety and quality control. Digital tools automate monitoring and testing, ensuring compliance and consistently high quality. Instead of manual checks and paperwork, automated solutions can flag concerns immediately, reducing risk and keeping customers safe.

The rise of online shopping has accelerated the importance of e-commerce adoption. Food brands are increasingly selling directly to consumers or business partners through digital channels. This not only broadens their market reach but also meets modern consumer expectations for convenience and fast service.

Digital change also enables more meaningful customer engagement. Think personalized marketing campaigns, loyalty programs, and deeper consumer insights. These digital connections create lasting relationships and loyalty, turning one-time buyers into lifelong fans.

When it comes to producing food, production automation is another game-changer. Robotics, IoT sensors, and AI-powered analytics streamline operations, improve consistency, and reduce the reliance on manual labor. The result? More efficient processes, lower costs, and safer working environments.

And finally, sustainability has become a top priority for consumers and regulators alike, pushing companies toward more responsible practices. Digital tools support sophisticated sustainability initiatives by monitoring and reducing environmental impacts, from energy and water use to packaging optimization and waste reduction.

How does digital change contribute to sustainability in the food industry?

Digital change is a powerful ally in the quest for sustainability in food businesses. With advanced analytics and real-time monitoring, companies can significantly cut down on waste—whether it’s reducing food waste in production or minimizing packaging materials. In fact, industry leaders who’ve acceptd digital solutions have been able to achieve impressive reductions in greenhouse gas emissions, energy, and water usage, sometimes by as much as half.

One key area where digital solutions shine brightest is energy efficiency. Smart sensors and cloud analytics platforms can closely track energy usage in production facilities, storage, and transportation. By pinpointing inefficiencies, companies save money while reducing their carbon footprint.

Similarly, digital monitoring can greatly improve water conservation. With sensors in place, food processors and agricultural operations can optimize water use, ensuring this precious resource is used efficiently and responsibly.

Digital tools also empower companies to accurately track and report their carbon footprints, providing transparency to customers and regulators. This transparency supports ongoing efforts to reduce emissions and develop greener operations.

Sustainable sourcing practices also benefit from digital technologies. Tools like blockchain and ERP software (NetSuite) give brands confidence and proof that their ingredients and supplies come from ethical, environmentally responsible sources. This boosts customer trust and helps build a healthier planet.

Lastly, digital solutions streamline packaging optimization and encourage circular economy practices. By digitally designing and testing sustainable packaging alternatives, food businesses can reduce waste without sacrificing product protection. Meanwhile, digital tracking supports recycling and reuse initiatives, contributing to a closed-loop system that’s kinder to the environment.

What ROI can food companies expect from digital change initiatives?

When considering an investment in digital change, it’s natural to wonder about the return you’ll see. While specific ROI varies depending on the initiatives you undertake, there are several common outcomes that food companies consistently experience.

One significant benefit is operational cost savings. Automating routine tasks, optimizing production processes, and using predictive maintenance solutions significantly reduce labor costs, material waste, and energy usage. Small to mid-sized manufacturing plants adopting ERP systems like NetSuite often see operating costs drop by an average of 11%.

Increased productivity is another significant ROI driver. Digital tools free employees from manual, time-consuming tasks. Teams become more productive, processes become smoother, and businesses can do more with less. This productivity uplift translates directly to improved profitability.

Quality improvements also contribute to ROI. Digital systems for quality control and monitoring quickly detect defects, reducing rework and waste. Products become more consistent, customer complaints go down, and brand reputation strengthens.

Speaking of waste, digital solutions significantly reduce waste across the business—in production, inventory management, and distribution. Real-time analytics prevent over-production and spoilage, saving valuable resources and money.

Better products and personalized experiences naturally improve customer satisfaction and loyalty. Satisfied customers return, buy more, and recommend your products to others, driving ongoing revenue growth.

As your food business becomes digitally agile, you’re better positioned to respond to market changes quickly. This adaptability helps you gain market share by launching new products faster, entering new markets seamlessly, and staying ahead of competitors.

Digital capabilities also become a meaningful competitive differentiator. While competitors are still wrestling with outdated systems, digitally transformed businesses deliver smoother customer experiences, higher quality products, and superior service. These advantages are challenging for slower-moving competitors to replicate.

Finally, digital change reduces the administrative load and risk associated with regulatory compliance. Automated monitoring and documentation slash the time it takes to ensure compliance, eliminating costly penalties and freeing your teams to focus on strategic tasks.

ROI timelines can vary—some “quick wins” deliver results in months, while larger initiatives may take longer. But the cumulative impact is significant. Studies show that three-quarters of food and beverage leaders report measurable improvements across all key performance indicators after embracing digital change.

At Nuage, we’ve helped countless food and beverage businesses successfully steer their digital change journey. We don’t just sell software; we partner with you to find the right digital solutions and guide you every step of the way.

Conclusion

Let’s face it: Food industry digital change isn’t just a buzzword—it’s a strategic necessity. If you want your food business to stay competitive, profitable, and resilient, embracing digital technology is essential.

Shifting your operations into the digital world might feel daunting at first. There’s new technology to learn, processes to redesign, and cultural changes to manage. But as we’ve seen throughout this guide, the payoff makes it all worth the effort. Companies that take the leap into digital change see real, measurable benefits like smoother operations, lower costs, stronger compliance, and happier customers.

The key to successful digital change isn’t just buying new tech—it’s about carefully balancing technology, processes, and people. You don’t just bolt on an ERP system and call it a day (trust us, we’ve seen companies try that—not pretty). Instead, you rethink your business from the ground up, asking how new digital tools can make your entire operation better.

At Nuage, we’ve spent over 20 years helping food and beverage companies steer their digital journeys. We’ve partnered closely with businesses just like yours, supporting them through every step of selecting, implementing, and optimizing their ERP solutions. We don’t push a particular software; rather, we take the time to understand your unique challenges and opportunities, then help you choose the best path forward.

The food industry is changing at lightning speed, driven by consumer demands, regulatory pressures, and rapid technological advancements. Now more than ever, waiting on the sidelines isn’t an option. The future belongs to businesses that see food industry digital change not as a hurdle, but as an opportunity to grow and thrive.

Check out our NetSuite 101 resource, or get in touch to find how Nuage can guide your food business on this exciting digital journey.