ERP solutions for manufacturing have become the backbone of digital change in today’s industrial landscape. These systems empower manufacturers by offering automation, real-time analytics, and seamless integration that improve efficiency, streamline processes, and optimize production. As companies face increasing pressure to adapt to market demands, ERP tools not only ensure compliance and improve decision-making but also foster innovation.

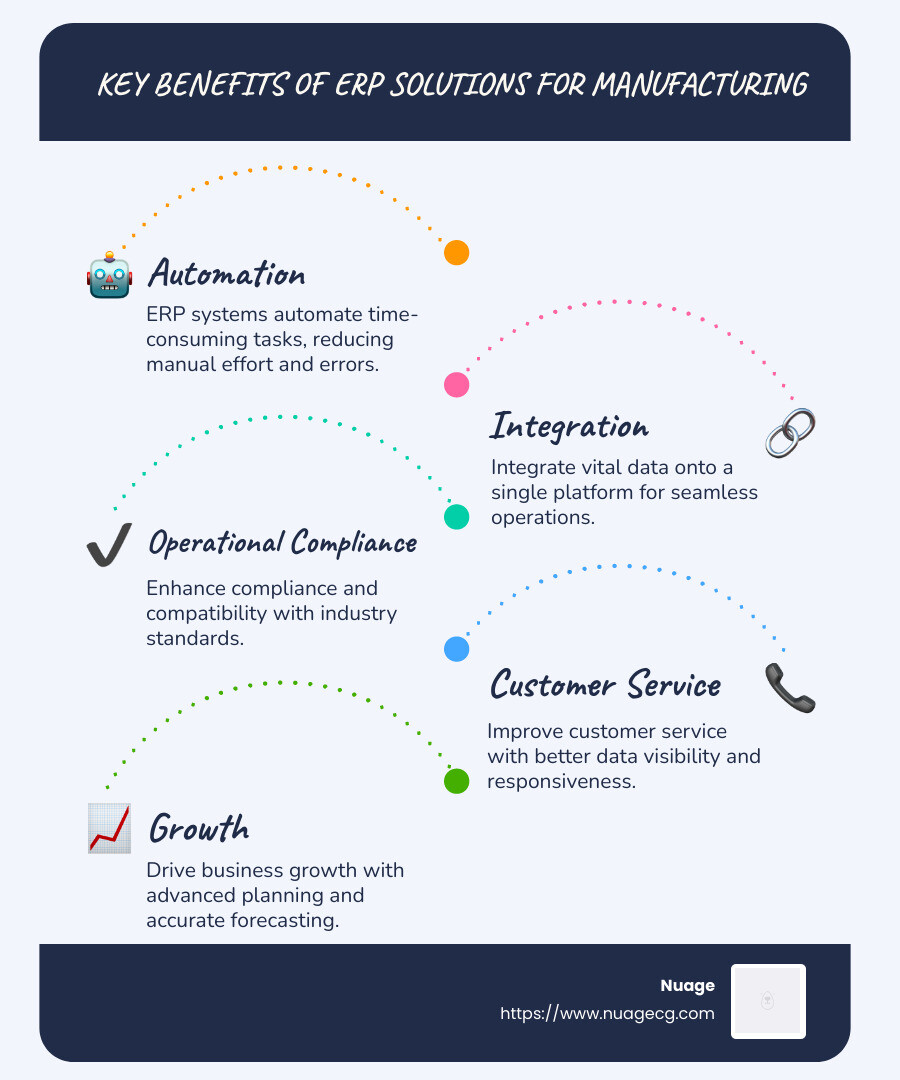

By embracing ERP solutions for manufacturing, businesses can:

- Automate time-consuming tasks.

- Integrate vital data onto a single platform.

- Improve operational compliance and compatibility.

- Improve customer service with better data visibility.

- Drive growth with advanced planning and forecasting.

This article digs deeper into how these transformative technologies are shaping the future of manufacturing industries. Learn from experts in the field and uncover opportunities for growth with solutions like NetSuite.

I’m Louis Balla, with over 15 years in digital change and ERP systems, especially in the field of NetSuit. My expertise helps businesses capitalize on the transformative power of ERP solutions for manufacturing, ensuring streamlined operations and significant return on investment.

Now, let’s explore what makes these ERP systems essential for modern manufacturing.

ERP solutions for manufacturing word list:

– ERP for beverage manufacturers

– ERP solutions for food

Understanding ERP Solutions for Manufacturing

When it comes to ERP solutions for manufacturing, integration is the magic word. These systems bring together every part of a manufacturing business, from accounting to production, into one unified platform. This means no more scattered data or siloed departments. Instead, you get a seamless flow of information that helps everyone stay on the same page.

Process optimization is another key benefit. With ERP, manufacturers can streamline operations, reduce waste, and improve efficiency. For example, automated production planning and scheduling help ensure that materials and resources are used optimally. This not only cuts costs but also boosts productivity. A well-optimized process means fewer bottlenecks and more consistent output.

Real-time data is a game-changer. With ERP systems, manufacturers can access up-to-the-minute information about inventory levels, production status, and sales trends. This visibility allows for quick decision-making and the ability to respond to changes in demand or supply. Imagine being able to adjust production schedules in real-time to meet unexpected spikes in customer orders. That’s the power of real-time data.

ERP systems like NetSuite are designed to support these integrations and optimizations. They provide a comprehensive suite of tools that help manufacturers manage everything from the shop floor to the top floor. With these systems, businesses can stay competitive in a rapidly changing market.

In summary, ERP solutions for manufacturing are all about integration, process optimization, and real-time data. They provide the foundation for a more efficient, responsive, and profitable manufacturing operation. The role of ERP in manufacturing will continue to grow, offering even more opportunities for innovation and success.

Top ERP Modules for Manufacturers

When diving into ERP solutions for manufacturing, understand the key modules that drive efficiency and productivity. Let’s explore the top modules that manufacturers rely on:

Materials Requirement Planning (MRP)

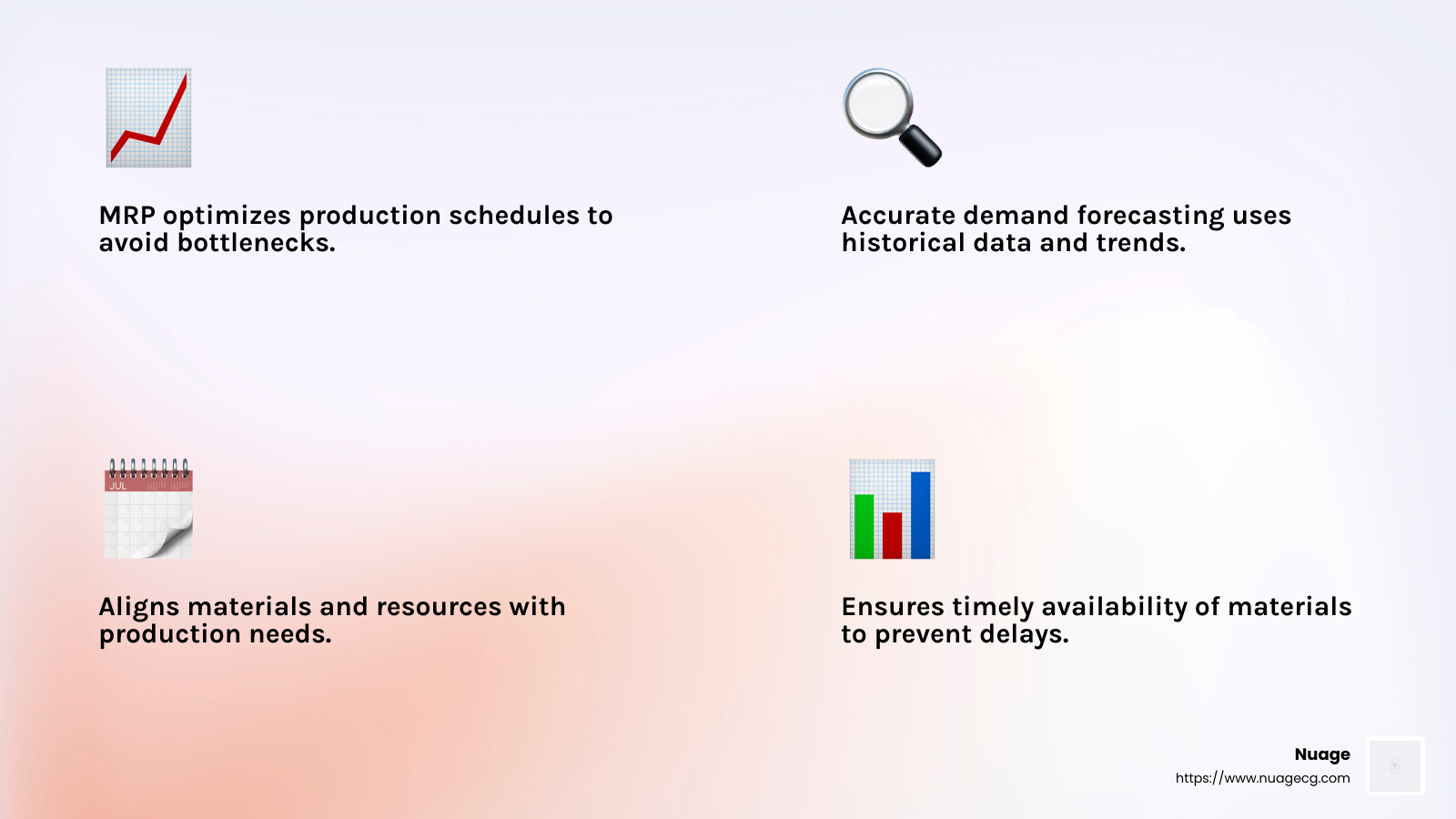

Materials Requirement Planning (MRP) is the backbone of production scheduling and demand forecasting. This module helps manufacturers determine what materials are needed, when they’re needed, and in what quantities. By doing so, it ensures that production runs smoothly without delays or excess inventory.

MRP systems allow manufacturers to:

- Optimize production schedules: Align materials and resources with production needs to avoid bottlenecks.

- Forecast demand accurately: Use historical data and trends to predict future demand and adjust production plans accordingly.

Inventory Management

An effective inventory management module is crucial for maintaining the right balance of stock. With real-time data, manufacturers can track inventory levels across multiple warehouses, ensuring they never run out or overstock items.

Key features of inventory management include:

- Multi-warehouse tracking: Manage inventory across different locations with ease, ensuring optimal stock levels everywhere.

- Stock control: Automatically reorder materials based on actual demand, reducing holding costs and minimizing waste.

Learn more about how NetSuite’s inventory management capabilities can streamline your operations.

Supply Chain Management

Supply chain management is all about strengthening vendor relationships and controlling costs. This module integrates supplier and vendor data, allowing manufacturers to make informed purchasing decisions and maintain strong relationships with their suppliers.

Benefits of supply chain management include:

- Vendor relationships: Evaluate suppliers on factors like delivery times, quality, and cost to choose the best partners.

- Cost control: Streamline purchasing processes to ensure you always have the right materials at the best prices.

By leveraging advanced supply chain management tools, manufacturers can keep their operations running smoothly and cost-effectively.

In conclusion, these ERP modules—MRP, inventory management, and supply chain management—are vital components of a successful manufacturing operation. They provide the tools needed to optimize production, manage inventory effectively, and maintain strong supplier relationships, all of which contribute to a more efficient and profitable business.

Benefits of Cloud-Based ERP Systems

In today’s manufacturing environment, cloud-based ERP solutions for manufacturing offer numerous advantages. These systems are designed to improve collaboration, enhance efficiency, and reduce costs. Let’s explore how they achieve this.

Improved Collaboration

One of the standout benefits of cloud-based ERP systems is improved collaboration. By centralizing data, these systems enable seamless data sharing across departments. Employees from accounting to production can access the same information in real-time, breaking down silos and fostering transparency.

This transparency ensures that everyone is on the same page, promoting better teamwork and faster decision-making. For instance, if there’s a delay in the supply chain, real-time data allows teams to adjust production schedules quickly, minimizing disruptions.

Improved Efficiency

Efficiency is at the heart of cloud-based ERP systems. By integrating real-time analytics, manufacturers can monitor operations continuously. This real-time insight helps identify bottlenecks and inefficiencies, allowing for swift corrective actions.

Moreover, cloud ERP systems offer scalability. As your business grows, the system can expand without the need for costly infrastructure investments. This flexibility ensures that your ERP solution evolves with your business needs.

An exciting development in cloud ERP is the integration of AI technologies. AI can automate routine tasks, such as data entry and report generation, freeing up employees to focus on more strategic activities. It can also provide predictive analytics, helping manufacturers anticipate market trends and adjust operations accordingly.

Streamlined processes are another key benefit. By automating workflows, cloud ERP systems reduce manual errors and improve productivity. For example, automated inventory management can ensure optimal stock levels, reducing both shortages and excesses.

Finally, cloud-based ERP systems contribute to cost reduction. With lower upfront costs compared to traditional systems, they offer a more affordable entry point for small and medium-sized manufacturers. Additionally, the software-as-a-service (SaaS) model can cut total ownership costs by 50% or more, delivering significant savings.

In summary, cloud-based ERP systems provide manufacturers with the tools they need for improved collaboration and efficiency. By leveraging real-time data, scalable solutions, and AI integration, these systems drive operational excellence and cost savings.

For more information on how these solutions can benefit your business, explore our pages on NetSuite. As we dig deeper into selecting the right ERP solution, we’ll explore how industry-specific needs can guide your choice.

Selecting the Right ERP Solution

Choosing the right ERP solutions for manufacturing is a critical step for any business aiming to streamline operations and drive growth. With the rapid pace of digital change, selecting an ERP system that aligns with your industry-specific needs and implementation strategies is crucial.

ERP Solutions for Manufacturing

When selecting an ERP system, it’s important to consider options that cater specifically to the manufacturing sector. One standout solution is NetSuite, which offers robust features tailored for manufacturers.

NetSuite is renowned for its scalability and integration capabilities. It is particularly beneficial for small to mid-sized manufacturers looking to transition from basic accounting software to a more comprehensive ERP system. With features like mobile ERP access, NetSuite ensures that manufacturers can manage their operations from anywhere, anytime. Learn more at NetSuite.

How Nuage Can Help

At Nuage, we understand the complexities involved in selecting and implementing the right ERP solution. Our team of experts provides guidance custom to your specific business needs, ensuring a smooth transition and successful integration of your chosen ERP system.

We specialize in helping businesses steer digital change by offering expert advice on the best practices for ERP implementation. Our strategies focus on minimizing disruptions while maximizing the benefits of your new system. Whether you’re a small business or a large enterprise, our goal is to empower you with the tools you need to succeed in today’s competitive manufacturing landscape.

By partnering with Nuage, you gain access to industry insights and personalized support, ensuring that your ERP system not only meets your current needs but also scales with your business as it grows.

We’ll address common questions and concerns about ERP solutions for manufacturing, helping you make informed decisions.

Frequently Asked Questions about ERP Solutions for Manufacturing

What is the difference between generic and manufacturing ERP systems?

Generic ERP systems are designed to be flexible and adaptable across various industries. They provide a broad range of features that can be customized to fit different business processes. However, this adaptability often requires additional configurations and customizations to meet the specific needs of a manufacturing company.

In contrast, manufacturing ERP systems are specifically custom to address the unique challenges and requirements of the manufacturing sector. These systems come equipped with industry-specific modules, such as production planning, quality control, and shop floor management, which are crucial for optimizing manufacturing operations. By focusing on manufacturing needs, these ERPs reduce the need for extensive customizations and provide a more streamlined implementation process.

How does cloud ERP improve manufacturing operations?

Cloud ERP offers several advantages that can significantly improve manufacturing operations. One of the primary benefits is real-time data access. With cloud-based systems, manufacturers can access up-to-date information from anywhere, facilitating better decision-making and faster response times to market changes.

Cloud ERP also improves collaboration and transparency by enabling seamless data sharing across departments. This ensures that everyone, from the shop floor to the executive suite, has access to the same information, reducing errors and improving communication.

Scalability is another key advantage. Cloud ERP systems can easily adjust to the changing needs of a business, whether it’s expanding operations or integrating new technologies like AI and IoT. This flexibility is essential for manufacturers looking to stay competitive in a rapidly evolving industry.

What are the key features of a manufacturing ERP system?

A robust manufacturing ERP system should include several essential features to support efficient operations:

- Materials Requirement Planning (MRP): This module helps in production scheduling and demand forecasting, ensuring that the right materials are available when needed.

- Inventory Management: Effective inventory control, including multi-warehouse management and stock level optimization, is crucial for reducing waste and improving efficiency.

- Supply Chain Management: This feature improves vendor relationships and cost control by providing visibility into the entire supply chain.

- Quality Management: Ensuring product quality through tools for quality control, compliance tracking, and audit management.

- Shop Floor Control: Real-time tracking of shop floor activities, including labor reporting and production output, to improve operational efficiency.

By incorporating these features, a manufacturing ERP system can streamline processes, reduce costs, and improve overall productivity. For more insights into how these systems can transform your manufacturing operations, explore our NetSuite solutions.

Conclusion

In the world of manufacturing, having the right tools is crucial for success. At Nuage, we understand the unique challenges faced by manufacturers and are committed to helping you steer the complexities of digital change. With over 20 years of experience, we are a trusted partner in selecting, implementing, and supporting ERP solutions custom specifically for the manufacturing sector.

Our expertise lies in providing comprehensive guidance and support for ERP solutions that drive efficiency, streamline processes, and improve productivity. We do not just sell software; we offer solutions that empower your business to thrive in a competitive landscape.

Why Choose Nuage?

- Expert Guidance: Our team of experts is well-versed in the intricacies of ERP systems, ensuring that you receive the best advice and support custom to your needs.

- Custom Solutions: We partner with leading ERP providers like NetSuite to deliver solutions that align with your specific manufacturing requirements.

- Proven Track Record: With a history of successful ERP implementations, we have helped numerous manufacturing businesses achieve their goals and improve their operations.

By partnering with Nuage, you gain access to a wealth of knowledge and resources that will help you build a better future for your manufacturing business. Whether you’re looking to improve collaboration, improve efficiency, or integrate cutting-edge technologies, we are here to guide you every step of the way.

Ready to transform your manufacturing operations? Let’s start on this journey together. Visit our NetSuite 101 page to learn more about how we can support your ERP needs.